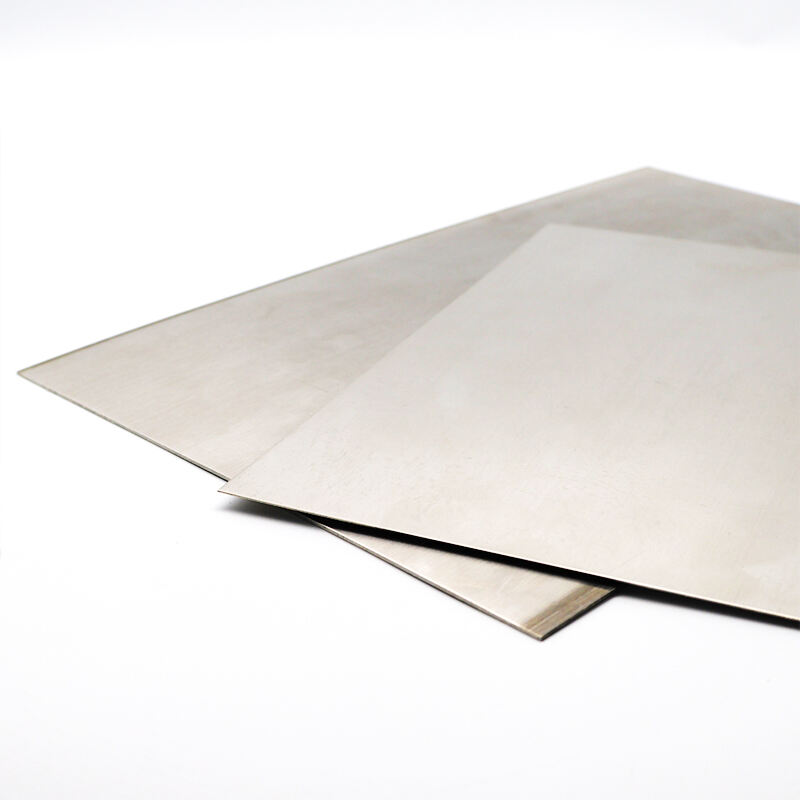

Високопрочні арматурні листи Monel K500 – ідеальні для екстремальних умов

Ми пропонуємо ціни напряму від заводу та спеціальні знижки для оптових замовлень. Незалежно від того, чи потрібні вам малі або великі кількості, наші продукти доставляються швидко, щоб забезпечити надійне постачання для промислових проектів у всьому світі.

- Огляд

- Специфікація

- Заявки

- Часто задані питання

- Рекомендовані продукти

- Нікель (Ni): 63.0% мінімум

- Мідь (Cu): 27,0-33,0%

- Алюміній (Al): 2,30-3,15%

- Титан (Ti): 0,35-0,85%

- Жалезо (Fe): ≤ 2,0%

- Манган (Mn): ≤ 1,5%

- Вуглець (C): ≤ 0.25%

- Кремній (Si): ≤ 0.50%

- Сір (S): ≤ 0.010%

- Використовується у суднобудуванні, валів вісів гребілки, насосних імпелерів та теплообмінників.

- Відмінна стійкість до солонаводної води та біологічного забруднення у морському середовищі.

- Застосовується у компонентах підводних човнів та платформ офшорного бурення.

- Використовується у компонентах літаківих двигунів, шасі для посадки та систем ракет.

- Витримує температурні коливання на висоті та атмосферну корозію.

- Застосовується у конструкціях супутників та космічних апаратів, яким потрібна легка та міцна тривалість.

- Використовується у клапанах, валках насосів та бурових інструментах для надморського та глибинного бурення.

- Стійкий до сірководню (H2S) та високотискових середовищ з кислого газу.

- Застосовується у системах трубопроводів, компонентах добових голов та петрохімічному обладнанні.

- Використовується у теплообмінниках, реакторах та тискових ємностях, що обробляють корозійні хімічні речовини.

- Стійкий до соляної кислоти, серної кислоти та промислових розчинників.

- Забезпечує тривалу експлуатаційну надійність у екстремальних хімічних середовищах.

- Застосовується у лопастях турбін, компонентах генераторів та системах ядерних реакторів.

- Видримує високе теплове та радіаційне навантаження.

- Використовується у парових турбінах, компонентах паливних стержнів та конструкціях радіаційного захисту.

- Вибір сировини: Використовуються високочисті билити з сплаву Монель K500.

- Гаряче і холодне прокатування: Сплав формують у листи з точними розмірами товщини і якісним поверхневим покриттям.

- Посилова термічна обробка: Термічна обробка підвищує міцність, твердість і стійкість до зношення.

- Кислотна обробка та пасивування: Призводить до вилучення поверхневих забруднень для покращення корозійної стійкості.

- Тестування якості та перевірки: Включає ультразвукове тестування, перевірку твердості та габаритних розмірів для відповідності стандартам ASTM B127 та ASME SB127.

- Можливості налаштування: Доступні у різних розмірах, товщині та поверхневих покриттях.

- Дуже замовлення та економічна ефективність: Постачання напряму від заводу забезпечує конкурентоспроможну ціну та великомасштабне виробництво.

- Сувора дотримка: Відповідає міжнародним стандартам якості для критичних галузей.

- Глобальна мережа розподілу: Забезпечує швидку доставку та надійне постачання у всьому світі.

Листи Monel K500 - це високопрочні матеріали з нікелево-мідного сплаву, призначені для екстремальних умов, де важлива корозійна стійкість, тривалість та механічна сила. Комбінується виняткова корозійна стійкість Monel 400 з додатковою силою та твердістю через утворення твердого фазового сплаву алюмінієм та титаном. Листи Monel K500 широко використовуються в морській, авіакосмічній, хімічній обробці та галузях нафтогазової промисловості.

Огляд матеріалу – Monel K500 (UNS N05500)

Monel K500 - це сплав на основі нікеля з покращеними властивостями завдяки додаванню алюмінію (Al) і титану (Ti), що значно підвищують механічну силу, стійкість до зносу та твердість за допомогою процесу старіння.

Хімічний склад Монелю K500

Основні властивості листів Monel K500

✔ Висока міцність та твердість: до двох разів міцніше, ніж Монель 400, завдяки умові старіння.

✔ Відмінна корозійна стійкість: виняткова стійкість до солонаводної води, кислотних та основних середовищ.

✔ Відмінна стійкість до зносу та ерозії: ідеальна для високонавантажених застосувань у важких промислових умовах.

✔ Добра теплопровідність та електропровідність: придатна для високотемпературних застосувань.

✔ Немагнітна у стані анілювання: зберігає магнітну стійкість при низьких температурах.

Застосування аркушів Monel K500

1. Морська та шельфова промисловість

2. Авіаційна та космічна промисловість

3. Галузь нафтогазової промисловості

4. Хімічна та переробнича промисловість

5. Виробництво електроенергії та ядерна промисловість

Технологічний процес виготовлення листів Monel K500

Потреба ринку та вимоги клієнтів

Зростаюча промислова потреба у матеріалах з високою міцністю та корозійною стійкістю призводить до широкого використання аркушів Монель K500 у галузях, де потрібна тривала тривалість та ефективність.

Поширені запитання:

Скільки часу триває доставка?

Залежить від кількості замовлення, для малих замовлень 10-30 днів. Для великих замовлень потрібно 60 днів.

Чи приймаєте ви виробництво OEM/ODM?

Так! Ми приймаємо виробництво OEM/ODM. Ви можете надіслати нам свої зразки або малюнки.

Як ви контролюєте якість своїх продуктів? Чи відповідають хімічні властивості продуктів якісним стандартам?

З професійною командою якості, сучасним планированням якості продукції, строгим виконанням та неперервним покращенням, ми видаватимемо свідоцтво про перевірку якості продукції, включаючи звіт про хімічний аналіз.

Чи може ваша компанія надати детальні технічні дані та малюнки?

Так, може. Будь ласка, повідомте нас про продукти та застосування, які вам потрібні, і ми надішлемо вам детальні технічні дані та малюнки для оцінки та підтвердження.

Як ви обробляєте передпродажну та післяпродажну службу?

У нас є професійна комерційна команда, яка буде працювати один до одного, щоб захищати ваші потреби у продуктах, і якщо виникнуть будь-які питання, він зможе на них відповісти!

Чи можу я відвідати вашу фабрику, перш ніж зробити замовлення?

Так, ви можете відвідати нашу фабрику. Ми раді мати можливість познайомитися.

Де розташована ваша виробнича база?

Ми виготовляємо наші продукти в провінції Цзянсу, Китай, і відправляємо їх з Китаю до вашої країни якомога швидше, що зазвичай залежить від ваших вимог до продукту та кількості.

Чи можете ви надіслати зразки?

Так, ми можемо.