Khả năng chống ăn mòn tuyệt vời:

Đặc biệt có khả năng kháng ăn mòn do ứng suất clo (SCC), ăn mòn điểm và ăn mòn khe hở rất cao.

Tính ổn định ở nhiệt độ cao tốt:

Có thể hoạt động trong thời gian dài trong môi trường nhiệt độ cao mà không mất đi các đặc tính cơ học hoặc bị oxi hóa.

Độ mạnh và độ dai cao:

Duy trì độ bền kéo và độ dẻo ngay cả ở nhiệt độ cực thấp.

Khả năng kháng oxi hóa và cacbon hóa xuất sắc:

Phù hợp với môi trường oxi hóa và cacbon hóa ở nhiệt độ cao, vẫn giữ được các đặc tính vật lý sau thời gian sử dụng lâu dài.

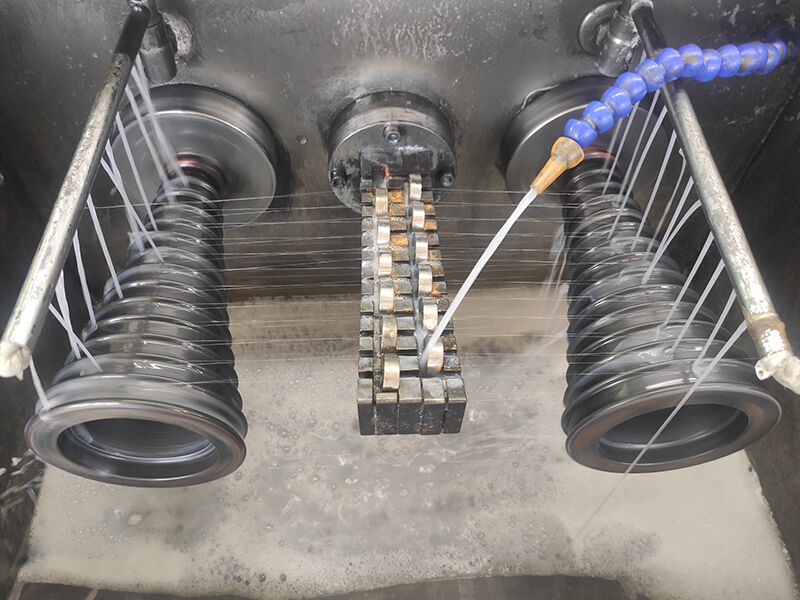

Hiệu suất gia công tốt:

Dễ hàn, tạo hình nóng và lạnh cũng như gia công, dễ chế tạo các sản phẩm có hình dạng phức tạp.

Không từ tính hoặc yếu từ tính:

Điều này khiến chúng phù hợp cho các ứng dụng nhạy cảm với trường từ.