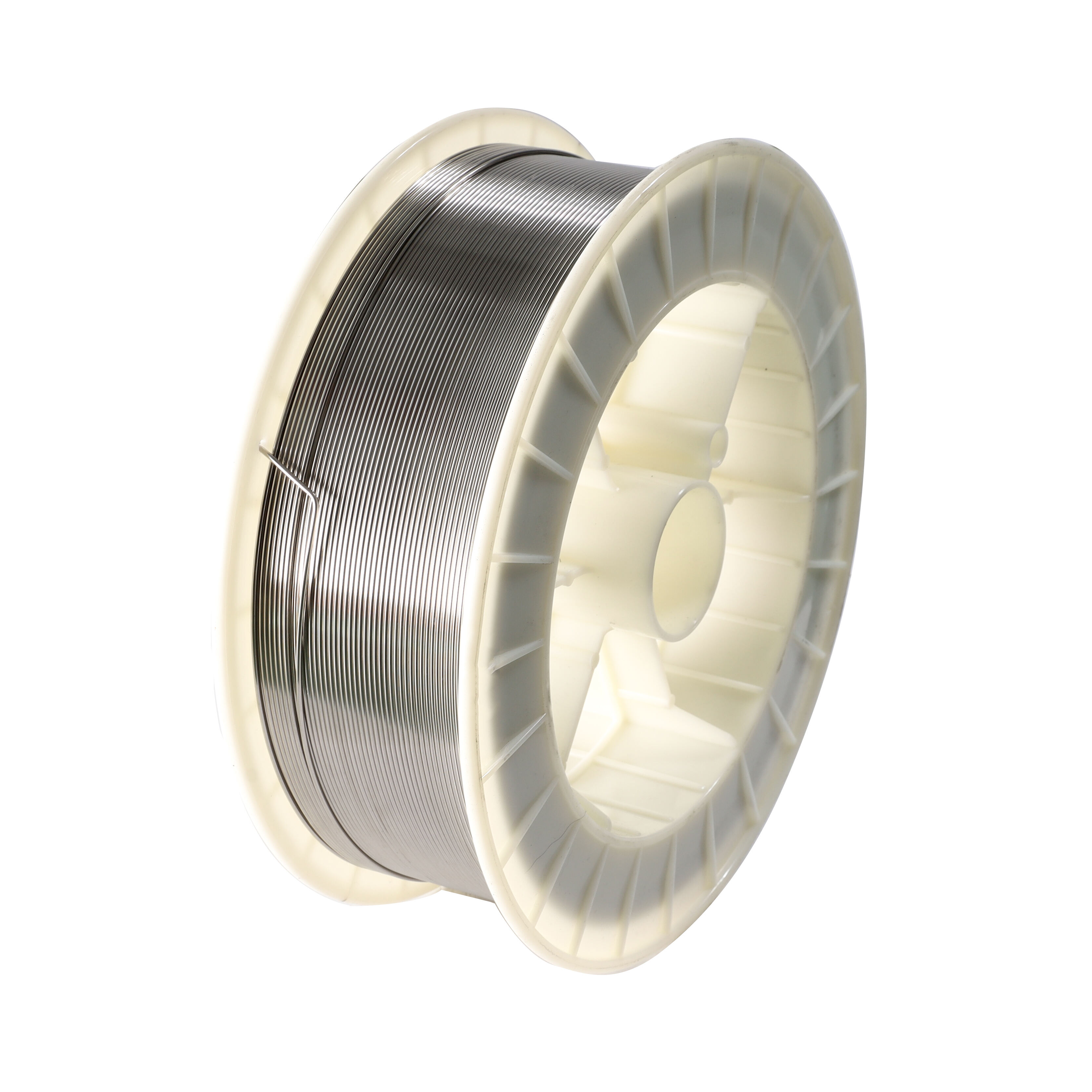

Dây hàn ERNiCrMo-4 (C-276) cho bộ trao đổi nhiệt – Thỏa thuận mua sỉ

Thêm:ERNiCrMo-3, ERNiCrMo-4, ERNiCrMo-13, ERNiCrFe-3, ERNiCrFe-7, ERNiCr-3, ERNiCr-7, ERNiCu-7, ERNi-1, ER70S-6. Chúng tôi cung cấp giá trực tiếp từ nhà máy với chiết khấu đặc biệt cho đơn đặt hàng số lượng lớn. Dù bạn cần số lượng nhỏ hay lớn, dây hàn ERNiCrMo-4 của chúng tôi luôn sẵn sàng giao hàng ngay, đảm bảo nguồn cung đáng tin cậy cho các dự án công nghiệp trên toàn thế giới.

- Tổng quan

- Các câu hỏi thường gặp

- Sản phẩm được đề xuất

Giới thiệu về dây hàn ERNiCrMo-4 (C-276)

Dây hàn ERNiCrMo-4 (C-276) là hợp kim dựa trên niken được thiết kế đặc biệt để hàn các vật liệu chống ăn mòn dùng trong trao đổi nhiệt, bình áp lực và các ứng dụng nhiệt độ cao khác. Với khả năng kháng ăn mòn tuyệt vời, chịu được nhiệt độ cực cao và tiếp xúc với hóa chất, hợp kim này được sử dụng rộng rãi trong chế biến hóa chất, nhà máy điện, dầu khí và ngành công nghiệp hàng hải.

Đối với các doanh nghiệp đang tìm kiếm các thỏa thuận mua sỉ, chúng tôi cung cấp giá trực tiếp từ nhà máy với số lượng hàng tồn kho lớn để đảm bảo cung cấp kịp thời cho các dự án quy mô lớn.

Tổng quan về vật liệu: Đặc tính của dây hàn ERNiCrMo-4 (C-276)

ERNiCrMo-4 (C-276), còn được biết đến với tên Hastelloy® C-276, được công nhận vì hiệu suất vượt trội trong các môi trường khắc nghiệt:

✔ Kháng ăn mòn xuất sắc – Bảo vệ khỏi hiện tượng ăn mòn điểm, ăn mòn khe hở và nứt do ăn mòn dưới stress trong các môi trường axit mạnh và giàu clo.

✔ Độ bền ở nhiệt độ cao – Giữ nguyên tính toàn vẹn cơ học ở nhiệt độ lên tới 1093°C (2000°F).

✔ Khả năng hàn tuyệt vời – Tạo ra các mối hàn mạnh, không có khuyết tật với mức nứt hoặc lỗ porosity tối thiểu.

✔ Độ kháng hóa học vượt trội – Chịu được các tác nhân oxy hóa và khử, bao gồm axit sunfuric, hydrocloric và nitric.

✔ Độ bền lâu dài – Đảm bảo tuổi thọ sử dụng kéo dài trong các ứng dụng công nghiệp khắc nghiệt.

Những đặc tính này làm cho ERNiCrMo-4 trở thành dây hàn lý tưởng cho bộ trao đổi nhiệt và các thiết bị quan trọng khác khi tiếp xúc với nhiệt độ cao và hóa chất tấn công.

| Tiêu chuẩn | Thông số kỹ thuật |

|---|---|

| AWS A5.14 | ERNiCrMo-4 |

| UNS Number | N10276 |

| Tiêu chuẩn ASTM | ASTM B574, ASTM B575 |

| Tiêu chuẩn ISO | ISO 18274: NiCr15Mo16Fe6W4 |

Ứng dụng của dây hàn ERNiCrMo-4 (C-276) cho bộ trao đổi nhiệt

Bộ trao đổi nhiệt phải chịu nhiệt độ cực đoan, áp suất cao và các chất lỏng ăn mòn, khiến dây hàn ERNiCrMo-4 (C-276) là giải pháp hoàn hảo để hàn các bộ phận của chúng.

1. Ngành công nghiệp chế biến hóa chất

Máy trao đổi nhiệt và Hệ thống làm mát – Cung cấp khả năng kháng axit mạnh và hóa chất ăn mòn.

Thùng phản ứng và Bồn chứa – Đảm bảo độ bền trong môi trường hóa học khắc nghiệt.

2. Sản xuất điện & ngành công nghiệp hạt nhân

Ống nồi hơi và Lò siêu nhiệt – Chịu được chu trình nhiệt và oxy hóa.

Turbine hơi nước và Khí – Bảo vệ khỏi sự suy giảm ở nhiệt độ cao.

3. Ngành dầu khí

Đơn vị thu hồi nhiệt và Nền tảng khai thác biển – Chống lại hiện tượng nứt do ứng suất sulfua và áp suất cực đại.

Xử lý LNG và Hóa dầu – Duy trì ổn định cấu trúc trong điều kiện nhiệt độ thấp.

4. Hàng không vũ trụ & Kỹ thuật hàng hải

Hệ thống xả động cơ phản lực – Chịu được nhiệt độ cao và oxy hóa.

Máy trao đổi nhiệt nước biển – Ngăn ngừa ăn mòn trong môi trường hàng hải.

5. Dược phẩm & Chế biến thực phẩm

Thiết bị trao đổi nhiệt vệ sinh – Đảm bảo hoạt động vệ sinh và không bị ô nhiễm.

Thiết bị khử trùng & Y tế – Cung cấp khả năng tương thích sinh học và chịu được điều kiện khử trùng cực đoan.

Tại sao Nên Chọn Sợi Hàn ERNiCrMo-4 (C-276) của Chúng Tôi?

✅ Ưu đãi Mua Sỉ Đặc Biệt – Giảm giá đặc biệt cho các dự án công nghiệp quy mô lớn.

✅ Hợp kim Chất lượng Cao được Chứng nhận – Đáp ứng tiêu chuẩn ngành AWS, ASTM và ISO.

✅ Kích thước & Bao bì Theo Yêu cầu – Có sẵn dạng cuộn, dây thừng và tùy chọn cắt theo chiều dài.

✅ Giao Hàng Toàn cầu Nhanh chóng & Uy tín – Đảm bảo cung cấp đúng hạn cho các dự án quan trọng.

✅ Cam Kết Có sẵn Hàng Trong Kho – Luôn có hàng cho các đơn đặt hàng số lượng lớn.

Thời gian giao hàng là bao lâu?

Tùy thuộc vào số lượng đơn hàng, 10-30 ngày cho đơn hàng nhỏ. Đối với đơn hàng lớn, mất 60 ngày.

Bạn có chấp nhận sản xuất OEM/ODM không?

Có! Chúng tôi chấp nhận sản xuất OEM/ODM. Bạn có thể gửi mẫu hoặc bản vẽ của bạn cho chúng tôi.

Bạn kiểm soát chất lượng sản phẩm như thế nào? Các đặc tính hóa học của sản phẩm có đáp ứng tiêu chuẩn chất lượng không?

Với đội ngũ chất lượng chuyên nghiệp, kế hoạch kiểm soát chất lượng sản phẩm tiên tiến, thực hiện nghiêm ngặt và cải tiến liên tục, chúng tôi sẽ cấp chứng chỉ kiểm tra chất lượng sản phẩm, bao gồm báo cáo phân tích hóa học.

thực hiện và cải tiến liên tục, chúng tôi sẽ cấp giấy chứng nhận kiểm tra chất lượng sản phẩm, bao gồm báo cáo phân tích hóa học.

Công ty của bạn có thể cung cấp dữ liệu kỹ thuật và bản vẽ chi tiết không?

Có, bạn có thể. Vui lòng cho chúng tôi biết sản phẩm và ứng dụng mà bạn cần, và chúng tôi sẽ gửi dữ liệu kỹ thuật và bản vẽ chi tiết để bạn đánh giá và xác nhận.

Bạn xử lý dịch vụ trước và sau bán hàng như thế nào?

Chúng tôi có một đội ngũ kinh doanh chuyên nghiệp sẽ làm việc một đối một để bảo vệ nhu cầu sản phẩm của bạn, và nếu bạn có bất kỳ câu hỏi nào, họ có thể trả lời cho bạn!

Tôi có thể đến thăm nhà máy của bạn trước khi đặt hàng không?

Có, bạn rất được chào đón đến thăm nhà máy của chúng tôi. Chúng tôi rất vui có cơ hội để làm quen với nhau.

Nhà máy sản xuất của bạn ở đâu?

Chúng tôi sản xuất sản phẩm tại Giang Tô, Trung Quốc và sẽ vận chuyển chúng từ Trung Quốc đến quốc gia của bạn sớm nhất có thể, điều này thường phụ thuộc vào yêu cầu sản phẩm và số lượng của bạn.

Bạn có thể gửi mẫu không?

Ừ, chúng ta có thể.