Tubong Ni201 Pure Nickel 8mm-60mm | Paggawa ng Barko & Pagproseso ng Kimika

Nag-aalok kami ng presyo na direkta mula sa fabrica at espesyal na mga diskwento para sa mga bulaklak na order. Kailanman ay kailangan mo ng maliit o malaking dami, madalas na ipinapadala ang aming mga produkto upang siguraduhing may sapat na suplay para sa industriyal na mga proyekto sa buong mundo.

- Panimula

- Espesipikasyon

- Paggamit

- Mga FAQ

- Inirerekomendang mga Produkto

Ang Ni201 Pure Nickel Tube ay isang premium-grade, mataas na kalidad na produkto ng nickel na may higit na kakayahang magtakbo laban sa korosyon, mataas na thermal conductivity, at mahusay na mekanikal na lakas. May outer diameter na mula 8mm hanggang 60mm, ang tubo na ito ay madalas gamitin sa mga industriya tulad ng paggawa ng barko, kimikal na proseso, at pagprodyus ng kuryente.

Ginawa ayon sa mga pamantayan ng ASTM B161 at ASME SB-161, siguradong magiging relihiyos ang pagganap ng mga tubo ng nickel Ni201 sa mga malubhang kapaligiran, kabilang ang pagsamyo sa mga asido, alkali, at mataas na temperatura.

Pangunahing benepisyo

Higit na Kakayahang Magtakbo Laban sa Korosyon – Nagtatrabaho nang mahusay sa mga kapaligiran na pantao at kimikal.

Mataas na Thermal & Electrical Conductivity – Nagpapatakbo ng makabuluhang pagpapasa ng init at elektrikal na pagganap.

Malakas at Matatag – Nakikipagtagpo sa estabilidad sa mga mataas na temperatura at mekanikal na presyon.

Mababang Carbon Content – Minimizesthe graphitization at nagpapalakas ng resistensya sa intergranular corrosion.

Magagamit na Custom Sizes – Mga iba't ibang diametro, haba, at kapaligiran upang tugunan ang mga pangangailangan ng industriya.

Paggamit

1. Paggawa ng Barko at Maritimong Inhinyeriya

Ginagamit sa heat exchanger tubing, ballast water systems, at offshore structures.

Makabagong resistensya sa karumihan ng seawater, nagiging ideal ito para sa maritimong pipa at condensers.

2. Industriya ng Kimikal Processing

Kailangan para sa pagproseso ng mga korosibong quimika, kabilang ang mga asido at alkali.

Inaaply sa chemical reactors, condensers, at storage tanks para sa ligtas at matatag na pagganap.

3. Pagbibigay Enerhiya at Heat Exchangers

Madalas gamitin sa steam piping, turbines, at nuclear power systems.

High-temperature stability nagpapatakbo ng mabuting pamamaraan ng heat exchange at energy transfer.

4. Himpapawid at Mataas na Temperaturang Sistema

Pinapili para sa mga fuel lines, exhaust systems, at mga bahagi ng high-performance engine.

| Espesipikasyon | Mga detalye |

|---|---|

| Material | Ni201 Pure Nickel (≥99.6%) |

| Labas na Bantog (OD) | 8mm – 60mm |

| Kapal ng pader | 0.5mm – 5mm |

| Habà | 1000mm – 6000mm |

| Pamantayan | ASTM B161, ASME SB-161, GB/T 4435-1984 |

| Punto ng paglalaho | 1435°C (2615°F) |

| Tensile Strength | ≥380 MPa |

| Elektrikal na Resistivity | ≤0.099 Ω·mm²/m |

Bakit Magpili ng Mga Ni201 Nickel Tubes namin?

? Direktang Pagsubok mula sa Fabrika & Diskwento para sa Bulk Order

? Minsang Pagsusuri ng Kalidad & Pag-aayos sa mga Industriyal na Standars

? Magagamit ang Pagpasok (Mga Iba't Ibang Sukat & Espekifikasiyon)

? Pampandaigdigang Pagpapadala & Mabilis na Paghatid

Mga tanong:

Gaano katagal ang oras ng paghahatid?

Nakaka-depende sa dami ng order, 10-30 araw para sa maliit na mga order. Para sa malaking mga order, kailangan iyan ng 60 araw.

Tatanggap ba kayo ng OEM/ODM produksyon?

Oo! Tatanggap kami ng OEM/ODM produksyon. Maaari mong ipadala sa amin ang mga sample o drawing mo.

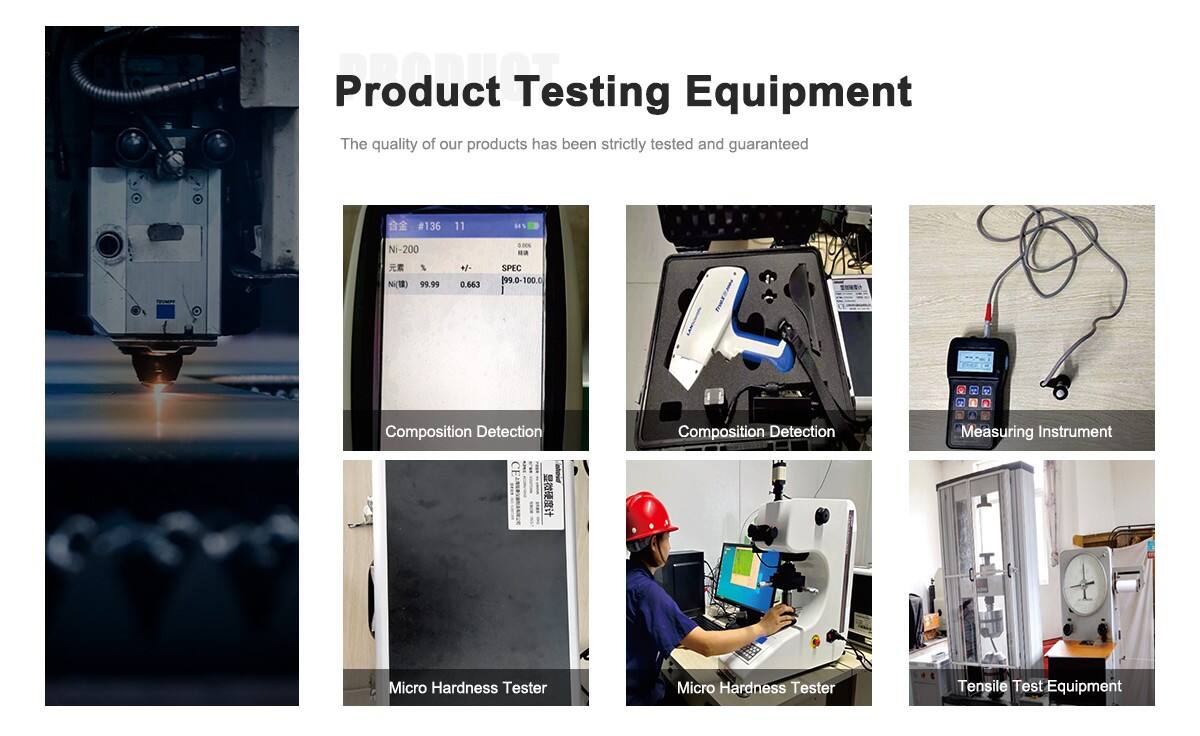

Paano kontrol ninyo ang kalidad ng inyong mga produkto? Nakakamit ba ng mga kemikal na katangian ng mga produkto ang mga estandar ng kalidad?

Sa pamamagitan ng propesyonang team ng kalidad, maunlad na pagpaplano ng kalidad ng produkto, matalik na pagsisikap at patuloy na pag-unlad, ihahanda namin sertipiko ng inspeksyon ng kalidad ng produkto, kabilang ang ulat ng analisis ng kemika.

Maaari ba ang inyong kompanya na magbigay ng detalyadong teknikal na datos at mga drawing?

Oo, maaari. Paki-abot sa amin ang mga produkto at aplikasyon na kailangan ninyo, at ipapadala namin ang detalyadong teknikal na datos at mga drawing para sa inyong pag-e-evalwate at konirmasyon.

Paano ninyo hahandle ang serbisyo bago at matapos ang pagsisimula?

Mayroon kami ng isang propesyonal na pangkalahatang team na magtatrabaho ng isa-sisa upang protektahan ang inyong mga pangangailangan sa produkto, at kung mayroon kang anumang tanong, maaaring sagutin niya ito para sa iyo!

Maaari ba akong bisitahin ang inyong fabrica bago mag-order?

Oo, mabibigyan ka ng permiso na bisitahin ang aming fabrica. Masaya kami na mayroon naming pagkakataon na makilala ang isa't-isa.

Saan matatagpuan ang inyong production base?

Gumagawa kami ng mga produkto sa Jiangsu, China at ipipadala namin ito mula sa China patungo sa inyong bansa ng maikling oras, na madalas ay depende sa mga requirement ng inyong produkto at dami.

Maaari mo bang magpadala ng mga sample?

Oo, maaaring gawin namin iyon.