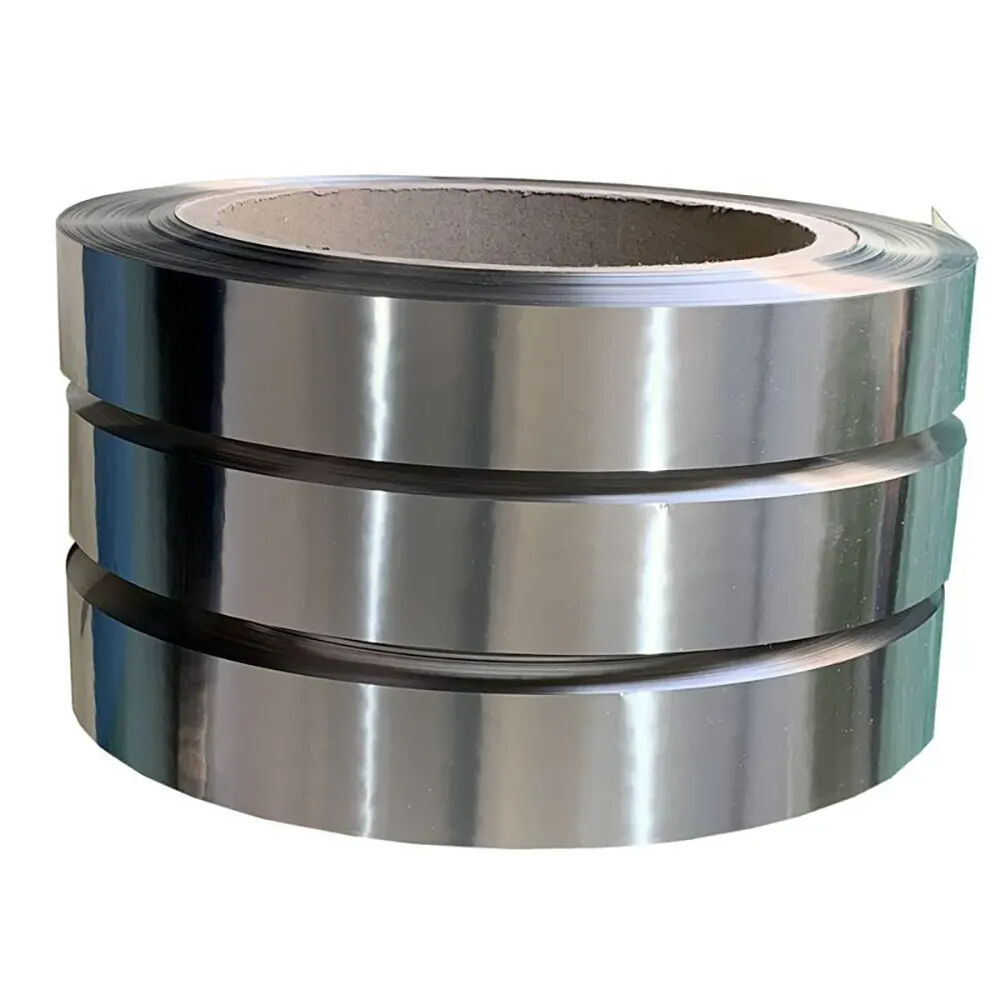

Incoloy 925 Strip para sa mga Aplikasyon ng Maritim & Aerospace – Mataas na Lakas

Nag-aalok kami ng presyo na direkta mula sa fabrica at espesyal na mga diskwento para sa mga bulaklak na order. Kailanman ay kailangan mo ng maliit o malaking dami, madalas na ipinapadala ang aming mga produkto upang siguraduhing may sapat na suplay para sa industriyal na mga proyekto sa buong mundo.

- Panimula

- Espesipikasyon

- Paggamit

- Mga FAQ

- Inirerekomendang mga Produkto

Pangunguna sa Incoloy 925 Strip

Ang Incoloy 925 ay isang mataas na lakas, korosyon-resistente na alahas base sa nikel na disenyo para sa mga demanding na aplikasyon sa industriya ng maritim at aerospesyal. Nag-aalok ito ng mahusay na kombinasyon ng mekanikal na lakas, resistensya sa mga kakaibang kapaligiran, at katatagan sa ilalim ng ekstremong temperatura at presyon.

Gumagamit ang Incoloy 925 strips sa mga kritikal na bahagi tulad ng mga parte ng eroplano, maritim na pagsasakay, at oilfield equipment. Ang kanilang napakabuting resistensya sa oksidasyon, pitting, at stress corrosion cracking ay nagiging sanhi kung bakit sila ay pinili bilang opsyon sa mga industriya na may mataas na pagganap.

Mga Punong Epekto ng Incoloy 925 Strips

Napakabuting Resistensya sa Korosyon – Mahusay na resistensya sa tubig dagat, asido, at mga kakaibang kemikal.

Mataas na Lakas at Katigasan – Pinagalingang mga mekanikal na characteristics para sa mga demanding application.

Kahanga-hangang Pagweld at Fabrication – Madali mong iproseso, kuttin, at hugutin sa iba't ibang bahagi.

Nakakabatong Estabilidad ng Init – Maganda ang pagganap sa mga ekstremong temperatura environments.

Resistente sa Stress Corrosion Cracking – Ideal para sa aerospace at offshore applications.

| Element | Komposisyon (%) |

|---|---|

| Nickel (Ni) | 42.0 – 46.0 |

| Kromium (Cr) | 19.5 – 22.5 |

| Tolang (Fe) | Balance |

| Molybdenum (Mo) | 2.5 – 3.5 |

| Titanium (Ti) | 1.9 – 2.4 |

| Aluminum (Al) | 0.1 – 0.5 |

| Copper (Cu) | 1.5 – 3.0 |

| Buhangin (C) | ≤ 0.03 |

Mga Pamamaraan ng Incoloy 925 Strip

1. Industriya ng Aerospesyal

Ginagamit sa jet engines, exhaust systems, at mga bahagi ng anyo ng eroplano.

Matatag na suporta sa timbang at resistensya sa oksidasyon na nagpapabuti sa pagganap.

2. Maritima & Offshore Engineering

Inaaplay sa mga seawater piping system, propeller shafts, at marine fasteners.

Nakakabanggit na resistensya sa korosyon na dulot ng chloride at biofouling.

3. Industriya ng Oil & Gas

Ginagamit sa tubing, downhole equipment, at wellhead components.

Matatag sa mga kapaligiran ng mataas na presyon at mataas na temperatura (HPHT).

4. Prosesong Kimikal at Pagbibigay Enerhiya

Ginagamit sa heat exchangers, reactor vessels, at industriyal na boilers.

Resistente sa mabubuting asido at korosibong industriyal na kondisyon.

Proseso ng Paggawa ng Incoloy 925 Strips

Paggising ng Materyales – Pinipili ang mataas kwalidad na nickel, chromium, at iron alloys.

Pagmimelt at Pag-alloy – Nililikha gamit ang advanced vacuum induction melting (VIM) o electric arc furnace (EAF) technology.

Hot & Cold Rolling – Ginagawa ang strips upang makamit ang eksaktong kalakasan kasama ang mahusay na ibabaw na pamamahid.

Pagsasamad at Pagsenyor – Nagpapabilis ng mekanikal na lakas at resistensya sa korosyon.

Pagpapabuti ng Ibabaw at Pagsusuri – Nag-aasigurado na sumusunod sa industriyal na pamantayan at mga kinakailangan ng customer.

Bakit Magpili ng Mga Incoloy 925 Strip sa Amin?

Direktang Pagbibigay mula sa Fabrika – Kagilingang Pribisyo para sa Batog

Magagamit sa Pasadyang Largura, Kapal, at Pagpolis ng Sarpis

Tinatanggap ang OEM at Bulk Orders

Matalik na Kontrol ng Kalidad at Pagsunod sa Pandaigdigang Pamantayan

Mabilis na Pagpapadala at Handa na Suporta para sa Mga Kliyente

Mga tanong:

Gaano katagal ang oras ng paghahatid?

Nakaka-depende sa dami ng order, 10-30 araw para sa maliit na mga order. Para sa malaking mga order, kailangan iyan ng 60 araw.

Tatanggap ba kayo ng OEM/ODM produksyon?

Oo! Tatanggap kami ng OEM/ODM produksyon. Maaari mong ipadala sa amin ang mga sample o drawing mo.

Paano kontrol ninyo ang kalidad ng inyong mga produkto? Nakakamit ba ng mga kemikal na katangian ng mga produkto ang mga estandar ng kalidad?

Sa pamamagitan ng propesyonang team ng kalidad, maunlad na pagpaplano ng kalidad ng produkto, matalik na pagsisikap at patuloy na pag-unlad, ihahanda namin sertipiko ng inspeksyon ng kalidad ng produkto, kabilang ang ulat ng analisis ng kemika.

Maaari ba ang inyong kompanya na magbigay ng detalyadong teknikal na datos at mga drawing?

Oo, maaari. Paki-abot sa amin ang mga produkto at aplikasyon na kailangan ninyo, at ipapadala namin ang detalyadong teknikal na datos at mga drawing para sa inyong pag-e-evalwate at konirmasyon.

Paano ninyo hahandle ang serbisyo bago at matapos ang pagsisimula?

Mayroon kami ng isang propesyonal na pangkalahatang team na magtatrabaho ng isa-sisa upang protektahan ang inyong mga pangangailangan sa produkto, at kung mayroon kang anumang tanong, maaaring sagutin niya ito para sa iyo!

Maaari ba akong bisitahin ang inyong fabrica bago mag-order?

Oo, mabibigyan ka ng permiso na bisitahin ang aming fabrica. Masaya kami na mayroon naming pagkakataon na makilala ang isa't-isa.

Saan matatagpuan ang inyong production base?

Gumagawa kami ng mga produkto sa Jiangsu, China at ipipadala namin ito mula sa China patungo sa inyong bansa ng maikling oras, na madalas ay depende sa mga requirement ng inyong produkto at dami.

Maaari mo bang magpadala ng mga sample?

Oo, maaaring gawin namin iyon.