ERNiCrMo-4 (C-276) Welding Wire para sa Mataas na Pagganap na Paggawa sa Industriya

Mas marami: ERNiCrMo-3,ERNiCrMo-4,ERNiCrMo-13,ERNiCrFe-3,ERNiCrFe-7,ERNiCr-3,ERNiCr-7,ERNiCu-7,ERNi-1, ER70S-6.

Nag-aalok kami ng presyo na direkta mula sa fabrica kasama ang espesyal na diskwento para sa mga bulaklak na order. Kailanman ang iyong kailangan ng maliit o malaking dami, available ang aming ERNiCrMo-4 welding wire para sa agad na pagpapadala, siguraduhin ang wastong suplay para sa mga industriyal na proyekto sa buong mundo.

- Panimula

- Paggamit

- Mga FAQ

- Inirerekomendang mga Produkto

Pangunguna sa ERNiCrMo-4 (C-276) Kabukiran

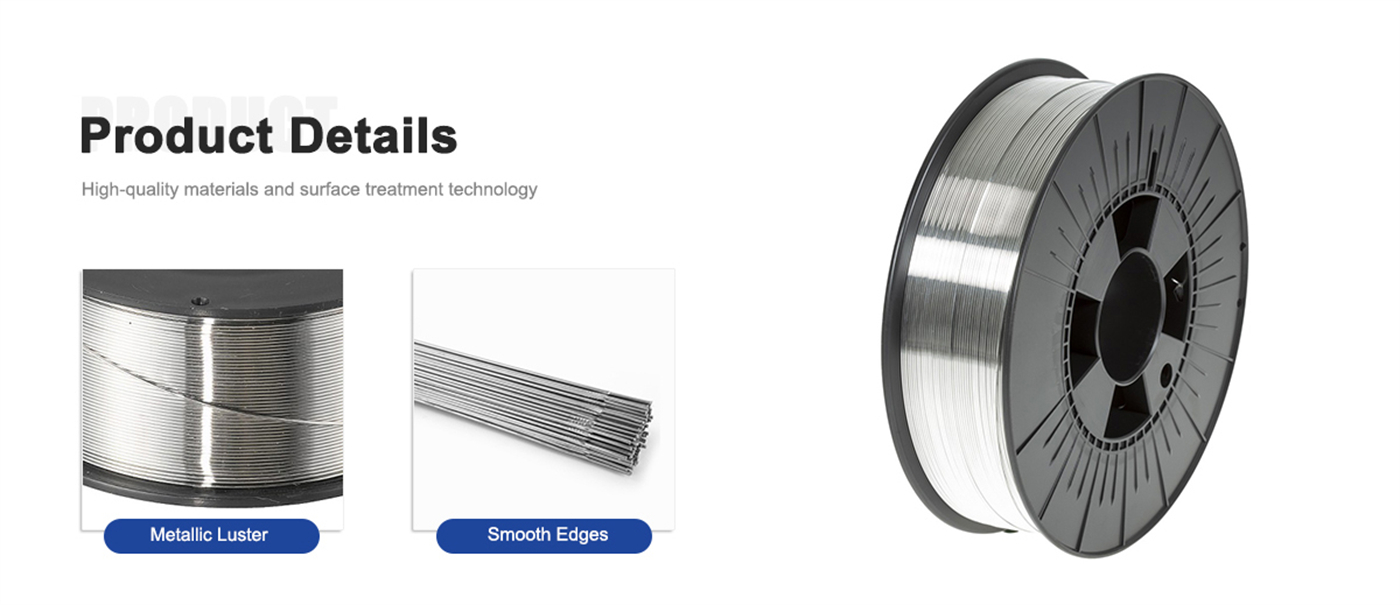

Ang ERNiCrMo-4 (C-276) welding wire ay isang nickel-base na alloy na disenyo para sa pagweld ng Hastelloy C-276 at iba pang mga korosyon-resistente na alloy. Nag-aalok ito ng eksepsiyonal na pagganap sa mga ekstremong industriyal na kapaligiran, gumaganap bilang pinili sa mga aplikasyon sa kimikal na proseso, langis & gas, elektrikong planta, eroplano, at marino na industriya.

Ang matalinong welding wire na ito ay kilala dahil sa kanyang napakatanging resistensya sa korosyon, matatag na temperatura sa mataas na lebel, at napakagandang mekanikal na lakas, nagpapatakbo ng tiyak na relihiyosong, walang defektong, at mahabang panahong pagweld.

Paglalarawan ng Materyales: Mga Katangian ng ERNiCrMo-4 (C-276) Kabuluan ng Wir

ERNiCrMo-4 ay isang alloy na may nickel, chromium, at molybdenum na may maliit na halaga ng iron at tungsten, na nagbibigay ng mahusay na resistensya sa oksidasyon, pitting, crevice korosyon, at stress corrosion cracking. Ito ay disenyo para gumawa ng trabaho sa mga kagubatan na malubhang asido, mayaman sa chloride, at mataas na temperatura.

Pangunahing Mga Tampok ng ERNiCrMo-4 (C-276) Welding Wire

✔ Mahusay na Resistensya sa Korosyon – Epektibo laban sa mga oxidizing at reducing agents, asido, at seawater korosyon.

✔ Pagganap sa Mataas na Temperatura – Makakabatian hanggang 1093°C (2000°F) nang walang pagkawala ng mekanikal na integridad.

✔ Mahusay na Kabidad sa Pagweld – Nagpapakita ng mabilis, walang sugat, at walang defektong welds, siguradong makabuo ng malakas at matatag na joints.

✔ Resistensya sa Kimikal at Asido – Resistente sa hydrochloric acid, sulfuric acid, nitric acid, at iba pang agresibong kimikal.

✔ Matagal na Tagal na Katatagan – Disenyo para sa malubhang industriyal na aplikasyon na kailangan ng ekstremong relihiyosidad.

Pamantayan at Espekifikasiyon ng Industriya

Ang aming ERNiCrMo-4 welding wire ay nililikha upang tugunan ang pinakamataas na pamantayan ng kalidad at pagganap, nagpapatakbo ng relihiabilidad para sa mga kritikal na aplikasyon.

Pamantayang Espekifikasiyon

AWS A5.14 ERNiCrMo-4

UNS Number N10276

ASTM Standard ASTM B574, ASTM B575

ISO Standard ISO 18274: NiCr15Mo16Fe6W4

Mga ito ay patunay na ang aming welding wire ay nakakatugon sa matalinghagang mga kinakailangan para sa industriyal na aplikasyon ng pagweld, nagbibigay ng konsistensya at masusing mga resulta.

Aplikasyon ng ERNiCrMo-4 (C-276) Welding Wire

Ang ERNiCrMo-4 welding wire ay malawakang ginagamit sa mga industriya na humihingi ng mataas na resistensya sa korosyon, toleransiya sa ekstremong temperatura, at matagal-mabuhay na pagganap ng weld.

1. Proseso ng Kimika at Petrokimika

Mga Tanke ng Pagtitipid at Pipela – Nagbibigay ng resistensya laban sa mga korosibong kimika, asido, at solvente.

Heat Exchangers at Reactors – Nagpapatibay ng katatagan sa agresibong mga kapaligiran ng kimika.

Bomba at Mga Saglit – Nagdidagdag ng haba ng buhay sa mga sistema ng transportasyon ng korosibong likido.

2. Industriya ng Oil & Gas

Mga Offshore Drilling Rig at Pipela – Nagpapigil sa korosyon ng tubig-dagat at hydrogen embrittlement.

LNG Storage at Cryogenic Processing – Magandang nagpapagana sa kondisyon ng mababang temperatura.

Mga Refineriya & Mga Catalytic Cracking Units – Makakatayo sa high-temperature oxidation at korosyon.

3. Mga Power Plants & Energy Sector

Mga Boilers & Heat Exchangers – Angkop para sa mga kondisyon ng mataas na temperatura at presyon.

Flue Gas Desulfurization (FGD) Systems – Protektahin sa korosyon ng mga acidic emissions.

Mga Komponente ng Nuclear Reactor – Nagbibigay ng resistensya sa radiation at thermal.

4. Aerospace & Marine Engineering

Mga Komponente ng Aircraft Engine – Siguradong may resistensya sa init at oxidasyon.

Marine Applications & Seawater Piping – Prevents saltwater korosyon at pagkasira.

5. Food Processing & Pharmaceutical Industry

Mga Equipments para sa Sterilization & Hygienic Piping – Nakakamantain ng malinis at korosyon-resistant na pagganap.

Bakit Magpili ng ERNiCrMo-4 (C-276) Welding Wire Natin?

Pamahalaang Premium at Direkta mula sa Manunuo – Nagpapatakbo ng konsistente at mataas na kalidad ng mga materyales.

Kumakatawan sa Kompetitibong Presyo at Bulk Discounts – Magagamit para sa mga pagsusulit sa mayakap na pamalitan ng presyo mula sa fabrica.

Mabilis na Paggagapang sa Buong Mundo – Nag-ofero kami ng pampailanglog na pagpapadala sa buong mundo.

Sertipikadong at Mataas na Pagganap na Materyales – Nakakamit ang industriyal na pamantayan ng AWS, ASTM, at ISO.

Custom Order Sizes – Available in spools, coils, and cut-to-length options.

Tiyak na Pagiging Available ng Stock – Handa para sa agad na pagpapadala.

Mga tanong:

Gaano katagal ang oras ng paghahatid?

Nakaka-depende sa dami ng order, 10-30 araw para sa maliit na mga order. Para sa malaking mga order, kailangan iyan ng 60 araw.

Tatanggap ba kayo ng OEM/ODM produksyon?

Oo! Tatanggap kami ng OEM/ODM produksyon. Maaari mong ipadala sa amin ang mga sample o drawing mo.

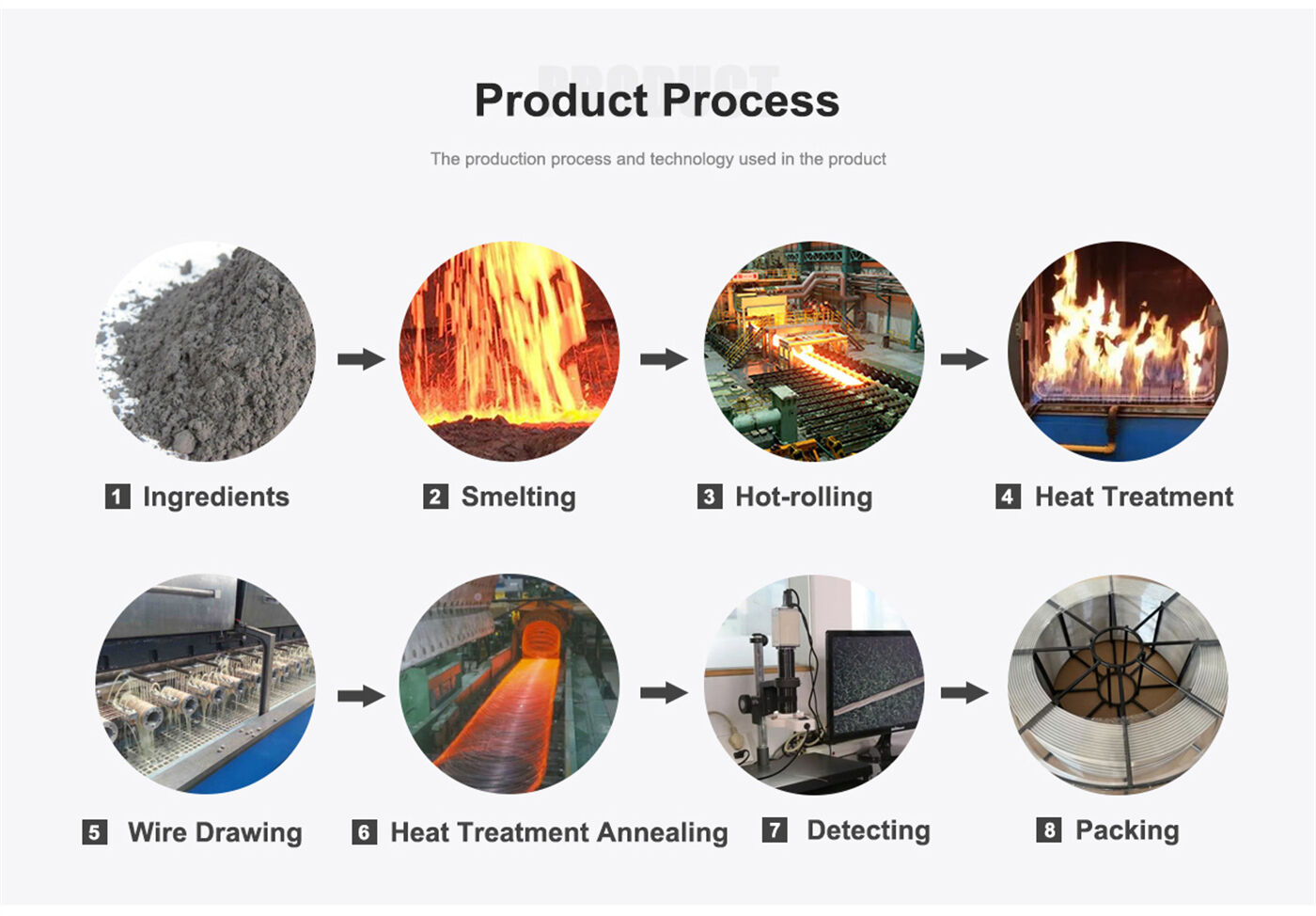

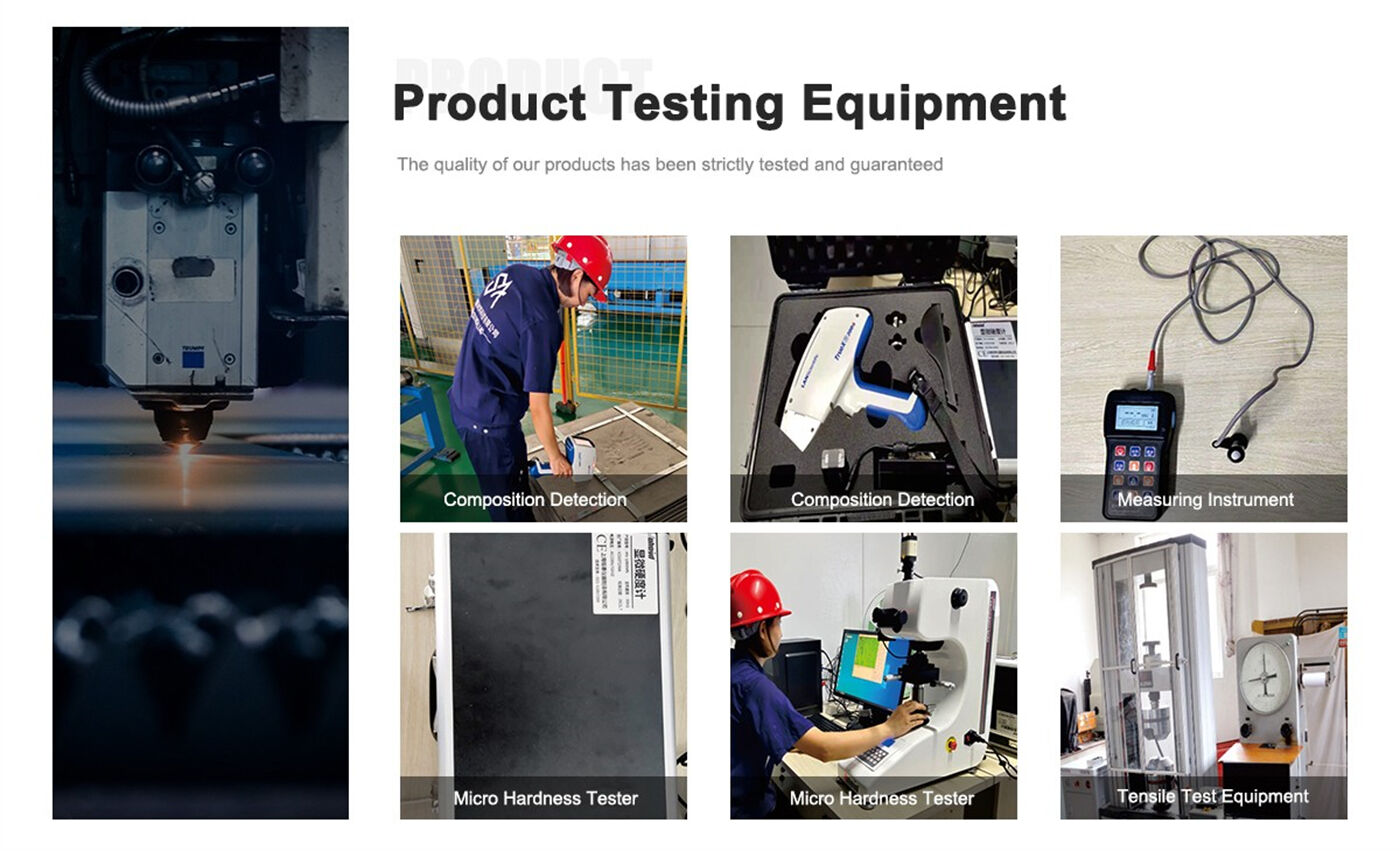

Paano kontrol ninyo ang kalidad ng inyong mga produkto? Nakakamit ba ng mga kemikal na katangian ng mga produkto ang mga estandar ng kalidad?

Sa pamamagitan ng propesyonang team ng kalidad, maunlad na pagpaplano ng kalidad ng produkto, matalik na pagsisikap at patuloy na pag-unlad, ihahanda namin sertipiko ng inspeksyon ng kalidad ng produkto, kabilang ang ulat ng analisis ng kemika.

Maaari ba ang inyong kompanya na magbigay ng detalyadong teknikal na datos at mga drawing?

Oo, maaari. Paki-abot sa amin ang mga produkto at aplikasyon na kailangan ninyo, at ipapadala namin ang detalyadong teknikal na datos at mga drawing para sa inyong pag-e-evalwate at konirmasyon.

Paano ninyo hahandle ang serbisyo bago at matapos ang pagsisimula?

Mayroon kami ng isang propesyonal na pangkalahatang team na magtatrabaho ng isa-sisa upang protektahan ang inyong mga pangangailangan sa produkto, at kung mayroon kang anumang tanong, maaaring sagutin niya ito para sa iyo!

Maaari ba akong bisitahin ang inyong fabrica bago mag-order?

Oo, mabibigyan ka ng permiso na bisitahin ang aming fabrica. Masaya kami na mayroon naming pagkakataon na makilala ang isa't-isa.

Saan matatagpuan ang inyong production base?

Gumagawa kami ng mga produkto sa Jiangsu, China at ipipadala namin ito mula sa China patungo sa inyong bansa ng maikling oras, na madalas ay depende sa mga requirement ng inyong produkto at dami.

Maaari mo bang magpadala ng mga sample?

Oo, maaaring gawin namin iyon.