Matibay na Hastelloy C-22 Plates – Pinakamura para sa Maraming Order

Nag-aalok kami ng presyo na direkta mula sa fabrica at espesyal na mga diskwento para sa mga bulaklak na order. Kailanman ay kailangan mo ng maliit o malaking dami, madalas na ipinapadala ang aming mga produkto upang siguraduhing may sapat na suplay para sa industriyal na mga proyekto sa buong mundo.

- Panimula

- Espesipikasyon

- Paggamit

- Mga FAQ

- Inirerekomendang mga Produkto

-

Kasangkapan na Resistente sa Korosyon: Nakakapigil sa pitting, crevice korosyon, at stress korosyon cracking sa mga mataas na korosibong media.

-

Katatagan sa Mataas na Temperatura: Nakikipagtamuhay ng mekanikal na lakas at resistensya sa korosyon sa mataas na temperatura.

-

Kabahalan: Sapat para sa paglilito, porma, at pag-machine, ginagawa itong ideal para sa makamplikadong fabricasyon.

-

Tagumpay sa Panahon: Nag-aalok ng extended serbisyo buhay, bumabawas sa pangangailangan ng maintenance at pagpapalit.

-

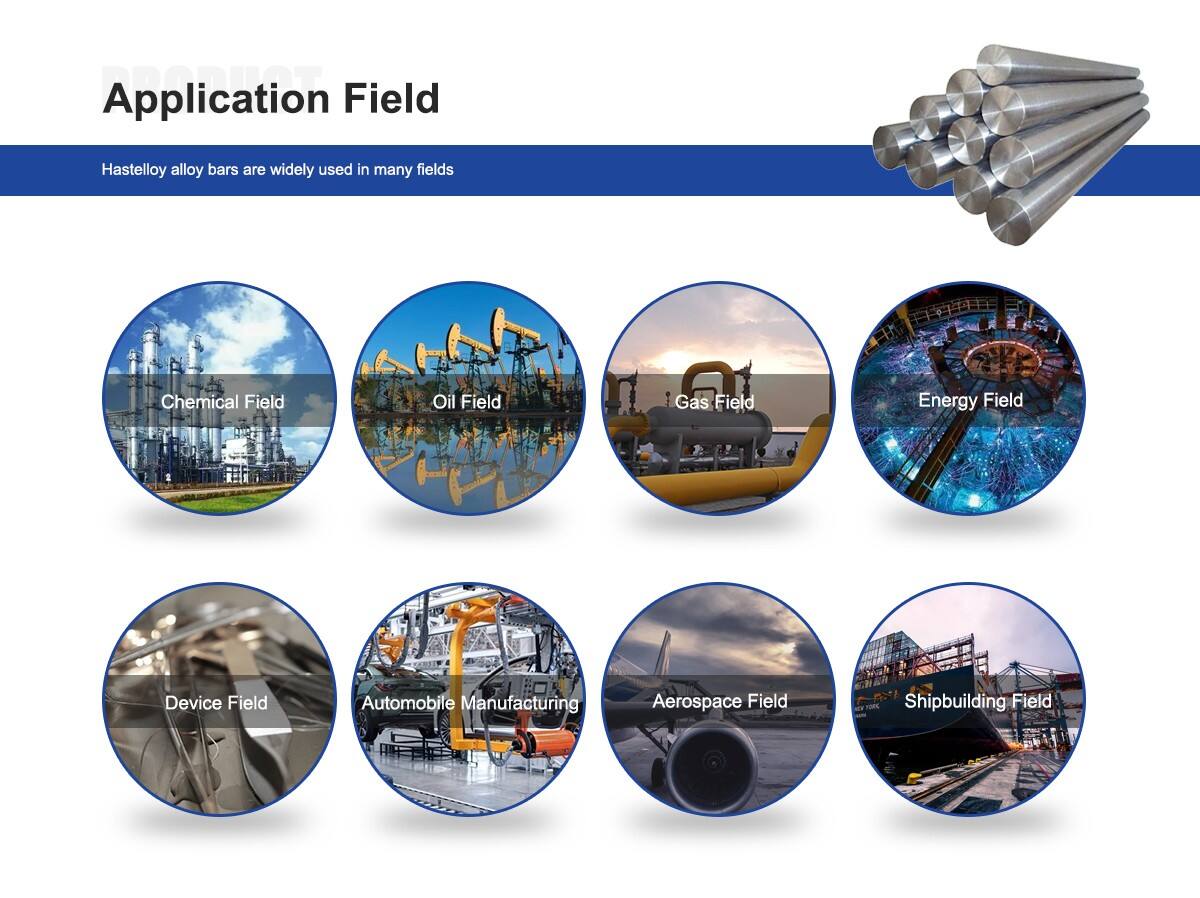

Pagsasala ng Kimika: Reactors, tanks, at heat exchangers na naghandla ng korosibong kimikal tulad ng asido sulfurico, asido hydrochloric, at mga chloride.

-

Pamamarili sa Pollution: Scrubbers, flue gas desulfurization systems, at waste treatment equipment.

-

Ahas at Gas: Downhole kagamitan, pipelines, at mga bahagi na esporsyon sa sour gas environments.

-

Industriya ng Farmasiya: Kagamitan para sa pagproseso ng agresibong APIs at intermediates.

-

Pagbibigay ng Enerhiya: Mga bahagi sa fossil fuel at nuclear power plants.

-

Industriya ng Pulp at Papel: Digesters at bleach plants na naghandla ng korosibong kimikal.

-

ASTM B575: Pambansang kaukulang patakaran para sa plato, sheet, at strip na anyong nickel alloy.

-

UNS N06022: Unipikadong Numero ng Sistemang Pagdadasal para sa Hastelloy C-22.

-

Pagmimeltsa at Pagbubuhos: Mga matuwid na anyong panggagamot ay nai-melt sa kontroladong atmospera at binubuo bilang slabs o ingots.

-

Paggigilingan ng Mainit: Ang nilabas na anyo ay iniinit at gigilin upang bawasan ang kapal at maabot ang inaasang sukat.

-

Paggigilingan ng Malamig (kung kinakailangan): Higit pa nang pagbawas ng kapal at mas mabuting katatagan ng ibabaw ay nakukuha sa pamamagitan ng paggigilingan ng malamig.

-

Annealing: Inaaplikahan ang tratamentong init upang alisin ang mga stress at optimisahin ang mekanikal na katangian.

-

Tratamentong Pampanlaban: Gigilid ang mga plato sa pamamagitan ng pickling, passivation, o iba pang tratamentong pangpampanlaban upang palakasin ang resistensya sa korosyon at kalidad ng ibabaw.

-

Pagsusulat at Pagwakas: Ang mga plato ay pinuputol ayon sa sukat at ginawa ayon sa mga espesipikasyon ng kliyente.

-

Katatagahan: Upang siguruhing mabilis na pagganap sa mahihirap na kapaligiran sa malalim na panahon.

-

Kostong-Epektibo: Bulk orders sa kompetitibong presyo upang bawasan ang kabuuang gastos ng proyekto.

-

Resistensya sa Korosyon: Upang minimizahin ang pagdadaloy ng kagamitan at mga gastos sa pagnanakaw.

-

Kabutihan sa Paggawa: Upang payagan ang walang siklab na pagweld, pagsasaklap, at pag-machine habang gumagawa ng kagamitan.

-

Ka relihiyosoan: Upang tiyakin ang konsistente na pagganap sa mga kritikal na aplikasyon.

-

Pinakamainam na Presyo: Kompetitibong presyo para sa mas maraming order, na nagiging isang ekonomikong solusyon para sa malalaking proyekto.

-

Konsistente na Kalidad: Mga parehong properti ng anyo at sukat sa lahat ng plato.

-

Mabilis na Pagpapadala: Epektibong produksyon at lohistik upang tugunan ang makikitid na deadliner ng proyekto.

-

Paggawang Pasadya: Kakayahan na magbigay ng mga plato sa tiyak na sukat, kapal, at acabado upang tugunan ang mga unikong kinakailangan.

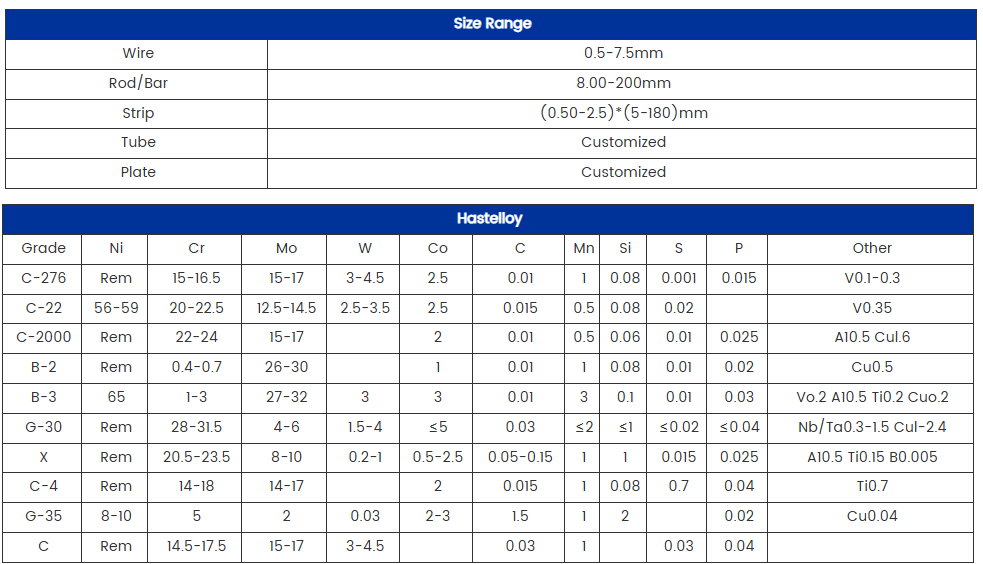

Ang Hastelloy C-22 ay isang alloy na nickel-chromium-molybdenum-tungsten na kilala dahil sa kanyang kamangha-manghang katatagan at resistensya sa korosyon sa mga ekstremong kalye. Kasama sa kanyang anyo ang nickel (Ni) bilang pangunahing elemento, chromium (Cr) para sa resistensya sa oksidasyon, molybdenum (Mo) at tungsten (W) para sa resistensya sa lokal na korosyon, at maliit na halaga ng iron (Fe) para sa dagdag na lakas. Ito ay espesyal na disenyo upang tiisin ang malubhang kondisyon, kabilang ang mataas na temperatura, asido at alkaleng kapaligiran, at pagsasanay sa chlorides at iba pang agresibong kemikal.

Pangunahing Katangian ng Platahang Hastelloy C-22:

Mga aplikasyon:

Ang mga plato ng Hastelloy C-22 ay madalas na ginagamit sa mga industriya na kailangan ng matatag na materiales para sa mahirap na operatibong kondisyon. Mga pangunahing aplikasyon pati na:

Mga Magagamit na Klase:

Ang Hastelloy C-22 plates ay magagamit sa mga standard na grado upang tugunan ang mga kinakailangan ng industriya:

Proseso ng paggawa:

Ang paggawa ng mga plato ng Hastelloy C-22 ay naglalagay sa maraming kritikal na hakbang upang siguraduhin ang mataas na kalidad at pagganap:

Mga Kailangan ng Gumagamit:

Ang mga industriya na umuugat sa Hastelloy C-22 plates ay pinaprioridad ang mga sumusunod:

Mga Kalakaran ng Order sa Bulk:

Para sa mga industriya na kailangan ng malaking dami, ang mga plato ng Hastelloy C-22 ay nagdadala ng mga siginificanteng kalakaran:

Mga tanong:

Gaano katagal ang oras ng paghahatid?

Nakaka-depende sa dami ng order, 10-30 araw para sa maliit na mga order. Para sa malaking mga order, kailangan iyan ng 60 araw.

Tatanggap ba kayo ng OEM/ODM produksyon?

Oo! Tatanggap kami ng OEM/ODM produksyon. Maaari mong ipadala sa amin ang mga sample o drawing mo.

Paano kontrol ninyo ang kalidad ng inyong mga produkto? Nakakamit ba ng mga kemikal na katangian ng mga produkto ang mga estandar ng kalidad?

Sa pamamagitan ng propesyonang team ng kalidad, maunlad na pagpaplano ng kalidad ng produkto, matalik na pagsisikap at patuloy na pag-unlad, ihahanda namin sertipiko ng inspeksyon ng kalidad ng produkto, kabilang ang ulat ng analisis ng kemika.

Maaari ba ang inyong kompanya na magbigay ng detalyadong teknikal na datos at mga drawing?

Oo, maaari. Paki-abot sa amin ang mga produkto at aplikasyon na kailangan ninyo, at ipapadala namin ang detalyadong teknikal na datos at mga drawing para sa inyong pag-e-evalwate at konirmasyon.

Paano ninyo hahandle ang serbisyo bago at matapos ang pagsisimula?

Mayroon kami ng isang propesyonal na pangkalahatang team na magtatrabaho ng isa-sisa upang protektahan ang inyong mga pangangailangan sa produkto, at kung mayroon kang anumang tanong, maaaring sagutin niya ito para sa iyo!

Maaari ba akong bisitahin ang inyong fabrica bago mag-order?

Oo, mabibigyan ka ng permiso na bisitahin ang aming fabrica. Masaya kami na mayroon naming pagkakataon na makilala ang isa't-isa.

Saan matatagpuan ang inyong production base?

Gumagawa kami ng mga produkto sa Jiangsu, China at ipipadala namin ito mula sa China patungo sa inyong bansa ng maikling oras, na madalas ay depende sa mga requirement ng inyong produkto at dami.

Maaari mo bang magpadala ng mga sample?

Oo, maaaring gawin namin iyon.