Премиальные листы Monel 400 – Высокая коррозионная стойкость для морских применений

Мы предлагаем заводские цены и специальные скидки для оптовых заказов. Независимо от того, нужны вам небольшие или крупные партии, наши продукты доставляются быстро, чтобы обеспечить надежное снабжение промышленных проектов по всему миру.

- Обзор

- Характеристики

- Применения

- Часто задаваемые вопросы

- Рекомендуемые продукты

-

Никель (Ni): не менее 63.0%

-

Медь (Cu): 28.0-34.0%

-

Железо (Fe): не более 2.5%

-

Марганец (Mn): не более 2.0%

-

Кремний (Si): не более 0.5%

-

Углерод (C): не более 0.3%

-

Сера (S): не более 0.024%

-

Высокая коррозионная стойкость: Отличная работа в морской, кислой и щелочной среде.

-

Превосходные механические свойства: Высокая прочность и вязкость даже при повышенных температурах.

-

Отличная теплопроводность: Эффективна для теплообменников и конденсаторных приложений.

-

Хорошая свариваемость: может легко свариваться и обрабатываться с использованием стандартных промышленных методик.

-

Морская промышленность: используется в судостроении, валов гребных винтов, морских водопроводных труб и морских платформ благодаря отличной устойчивости к коррозии соленой водой.

-

Химическая переработка: идеальна для обработки кислотных и щелочных веществ в реакторах, теплообменниках и резервуарах.

-

Нефтяная и газовая промышленность: используется в трубопроводах, клапанах и теплообменниках для морского бурения и нефтеперерабатывающих операций.

-

Авиакосмическая промышленность: используется в конструкционных элементах, которым требуется высокая прочность и устойчивость к коррозийным средам.

-

Производство электроэнергии: применяется в атомных и тепловых электростанциях для теплообменников и конденсаторов.

-

Медицинская промышленность: используется в специализированном оборудовании, требующем устойчивости к телесным жидкостям и условиям стерилизации.

-

Плавление и литье: высокоочищенные сырьевые материалы плавятся в вакуумной или электродуговой печи.

-

Горячая прокатка и холодная прокатка: сплав формируется в листы через контролируемые процессы прокатки.

-

Отжиг: тепловая обработка применяется для улучшения механических свойств и коррозионной стойкости.

-

Завершающая обработка поверхности: очистка, шлифовка или полировка улучшают качество поверхности и долговечность.

-

Контроль качества: строгие тестовые процедуры, включая ультразвуковой контроль, химический анализ и механические испытания, обеспечивают соответствие стандартам ASTM B127 и другим отраслевым нормам.

-

Настройка под требования: доступны различные толщины, ширины и виды поверхностной отделки для удовлетворения специфических потребностей проекта.

-

Оптовые поставки и экономическая эффективность: продажи напрямую с завода обеспечивают конкурентоспособные цены и более быструю доставку.

-

Строгое соответствие: продукция соответствует международным стандартам, что гарантирует качество и производительность.

-

Устойчивость и переработка: растущее внимание уделяется экологически чистым материалам и перерабатываемым никелевым сплавам.

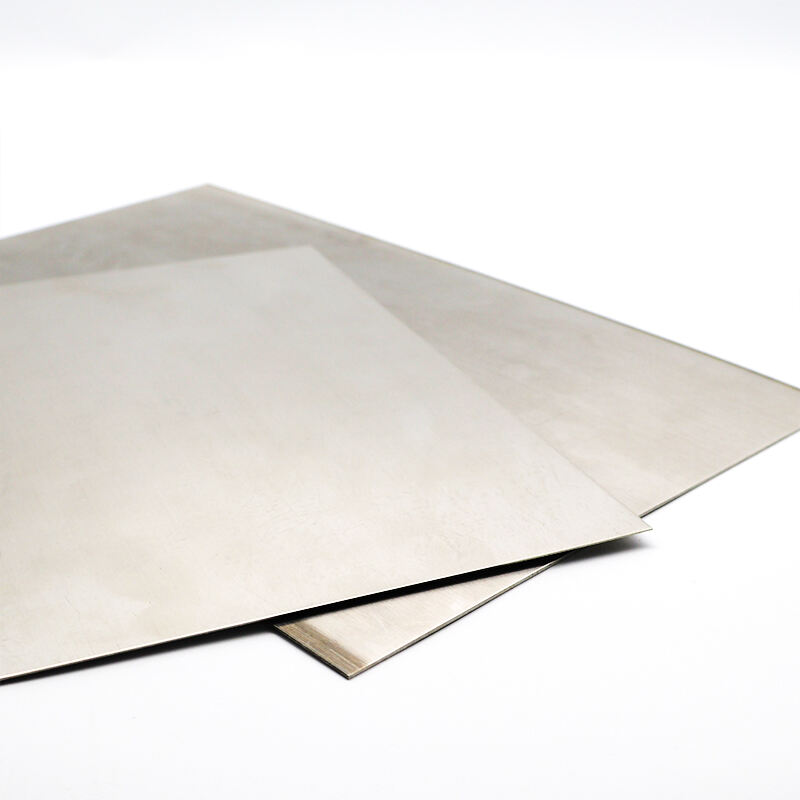

Введение в листы Монель 400

Листы Монель 400 широко используются в морской и промышленной сферах благодаря их исключительной коррозионной стойкости, прочности и долговечности. Как никелево-медный сплав, Монель 400 демонстрирует превосходные характеристики в суровых условиях, особенно в морской воде и химической переработке.

Обзор материала

Монель 400 (UNS N04400) является сплавом твердого раствора, главным образом состоящим из никеля и меди, с небольшими добавками железа, марганца, углерода и кремния. Этот состав обеспечивает ему отличную устойчивость к различным формам коррозии, включая точечную коррозию, щелевую коррозию и коррозионное растрескивание под напряжением.

Химический состав:

Характеристики листов Монель 400

Применение листов Монель 400

Благодаря исключительной коррозионной стойкости и прочности, листы Монель 400 широко используются в таких отраслях, как:

Процесс производства

Листы Монель 400 производятся через строгий технологический процесс, чтобы обеспечить высокое качество и надежность:

Спрос со стороны клиентов и рыночные тенденции

Глобальный спрос на листы Монель 400 растет из-за увеличения промышленных применений, требующих высокой коррозионной стойкости. Ключевые рыночные тенденции включают:

C

Часто задаваемые вопросы:

Сколько времени требуется для доставки?

Это зависит от количества заказа, 10-30 дней для малых заказов. Для крупных заказов требуется 60 дней.

Принимаете ли вы производство OEM/ODM?

Да! Мы принимаем производство OEM/ODM. Вы можете отправить нам свои образцы или чертежи.

Как вы контролируете качество своей продукции? Соответствуют ли химические свойства продукции стандартам качества?

С профессиональной командой по качеству, передовым планом планирования качества продукции, строгим исполнением и непрерывным улучшением, мы выдаем сертификаты проверки качества продукции, включая отчет о химическом анализе.

Может ли ваша компания предоставить подробные технические данные и чертежи?

Да, может. Пожалуйста, сообщите нам о необходимых продуктах и их применении, и мы отправим вам подробные технические данные и чертежи для оценки и подтверждения.

Как вы обрабатываете предпродажное и послепродажное обслуживание?

У нас есть профессиональная коммерческая команда, которая будет работать один на один, чтобы обеспечить ваши потребности в продуктах, и если у вас возникнут вопросы, он сможет ответить на них для вас!

Могу ли я посетить ваш завод перед размещением заказа?

Да, вы всегда можете посетить наш завод. Мы рады иметь возможность познакомиться поближе.

Где находится ваше производственное предприятие?

Мы производим свою продукцию в провинции Цзянсу, Китай, и отправляем её из Китая в вашу страну как можно скорее, что обычно зависит от ваших требований к продукции и количества.

Вы можете прислать образцы?

Да, мы можем.