Премиальная проволока для сварки ERNiCrMo-4 (C-276) – большая доступность на складе, заводская цена

Больше: ERNiCrMo-3,ERNiCrMo-4,ERNiCrMo-13,ERNiCrFe-3,ERNiCrFe-7,ERNiCr-3,ERNiCr-7,ERNiCu-7,ERNi-1, ER70S-6

- Обзор

- Рекомендуемые продукты

Введение в сварочную проволоку ERNiCrMo-4 (C-276)

Сварочная проволока ERNiCrMo-4 (C-276) является высокопроизводительным никелевым сплавом, разработанным для сварки никель-хром-молибденовых материалов в экстремальных условиях. Она широко используется в химической переработке, энергетике, нефти и газе, судостроении и авиакосмической промышленности благодаря своей превосходной коррозионной стойкости, высокой прочности и отличной свариваемости.

По нашим заводским ценам мы предлагаем премиальное качество сварочной проволоки ERNiCrMo-4 с большим наличием на складе, что обеспечивает стабильное снабжение для промышленных проектов по всему миру. Независимо от того, нужны ли вам небольшие или крупные партии, мы предоставляем быструю доставку и варианты индивидуальной упаковки для удовлетворения ваших специфических потребностей.

Обзор материала: свойства сварочной проволоки ERNiCrMo-4 (C-276)

ERNiCrMo-4 (C-276), также известный как Hastelloy® C-276, славится своими исключительными свойствами:

✔ Отличная коррозионная стойкость – Защищает от точечной коррозии, щелевой коррозии и коррозионного растрескивания под напряжением в высокоагрессивных кислотных и хлорсодержащих средах.

✔ Устойчивость при высоких температурах – Выдерживает экстремальную температуру до 1093°C (2000°F) без деградации материала.

✔ Превосходная свариваемость – Обеспечивает чистые, дефекты отсутствуют швы с минимальным риском трещин или пористости.

✔ Стойкость к сульфидному и хлоридному растрескиванию под напряжением – Идеально подходит для жестких промышленных условий на химических заводах и морских платформах.

✔ Высокие механические свойства – обеспечивают высокую прочность при экстремальных давлениях.

Эти характеристики делают сварочную проволоку ERNiCrMo-4 незаменимой для отраслей, требующих долговечных, коррозионностойких соединений.

Отраслевые стандарты и спецификации

Наша сварочная проволока ERNiCrMo-4 (C-276) соответствует международным стандартам качества, что обеспечивает высокую надежность и совместимость с критически важными сварочными применениями.

Стандартная спецификация

AWS A5.14 ERNiCrMo-4

UNS номер N10276

ASTM стандарт ASTM B574, ASTM B575

ISO стандарт ISO 18274: NiCr15Mo16Fe6W4

Это гарантирует, что наша сварочная проволока соответствует самым строгим промышленным требованиям по безопасности, долговечности и производительности.

Применения сварочной проволоки ERNiCrMo-4 (C-276)

1. Химическая перерабатывающая промышленность

Кислотные резервуары и трубопроводы – Защищают от коррозийных химических веществ, включая соляную и серную кислоты.

Теплообменники и реакторы – Обеспечивают долговечность в условиях высоких температур и давления.

Оборудование для смешивания химикатов – Предотвращает загрязнение и коррозионные неисправности.

2. Энергетика и атомная промышленность

Компоненты ядерного реактора – Устойчивы к радиации и экстремальной температуре.

Паровые и газовые турбины – Предоставляют защиту от окисления при высоких температурах.

Трубки котлов и системы рекуперации тепла – Выдерживают термический цикл и коррозию.

3. Нефтехимические и газовые заводы

Трубопроводы и морское оборудование – Сопротивляются растрескиванию под воздействием сульфидов (SSC) и водородному хрупкости.

Установки первичной переработки нефти – Выдерживают высокосернистые и кислотные среды.

Объекты СПГ и криогенные применения – Обеспечивают структурную целостность при низких температурах.

4. Авиакосмическая и морская инженерия

Компоненты реактивных двигателей – Идеальны для высокотемпературных и высокодавленных применений.

Судостроение и подводное оборудование – Предотвращают коррозию в соленой воде.

5. Промышленность пищевых продуктов и фармацевтики

Санитарная сварка оборудования для переработки пищевых продуктов – Обеспечивает гигиеническое и бесконтaminное производство.

Производство медицинских устройств – Предоставляет биосовместимость и устойчивость к стерилизации.

Почему стоит выбрать нашу сварочную проволоку ERNiCrMo-4 (C-276)?

Цены от производителя – Конкурентоспособные оптовые тарифы для крупных заказов и OEM-клиентов.

Высокая доступность запасов – Готовый к отправке инвентарь для срочных промышленных проектов.

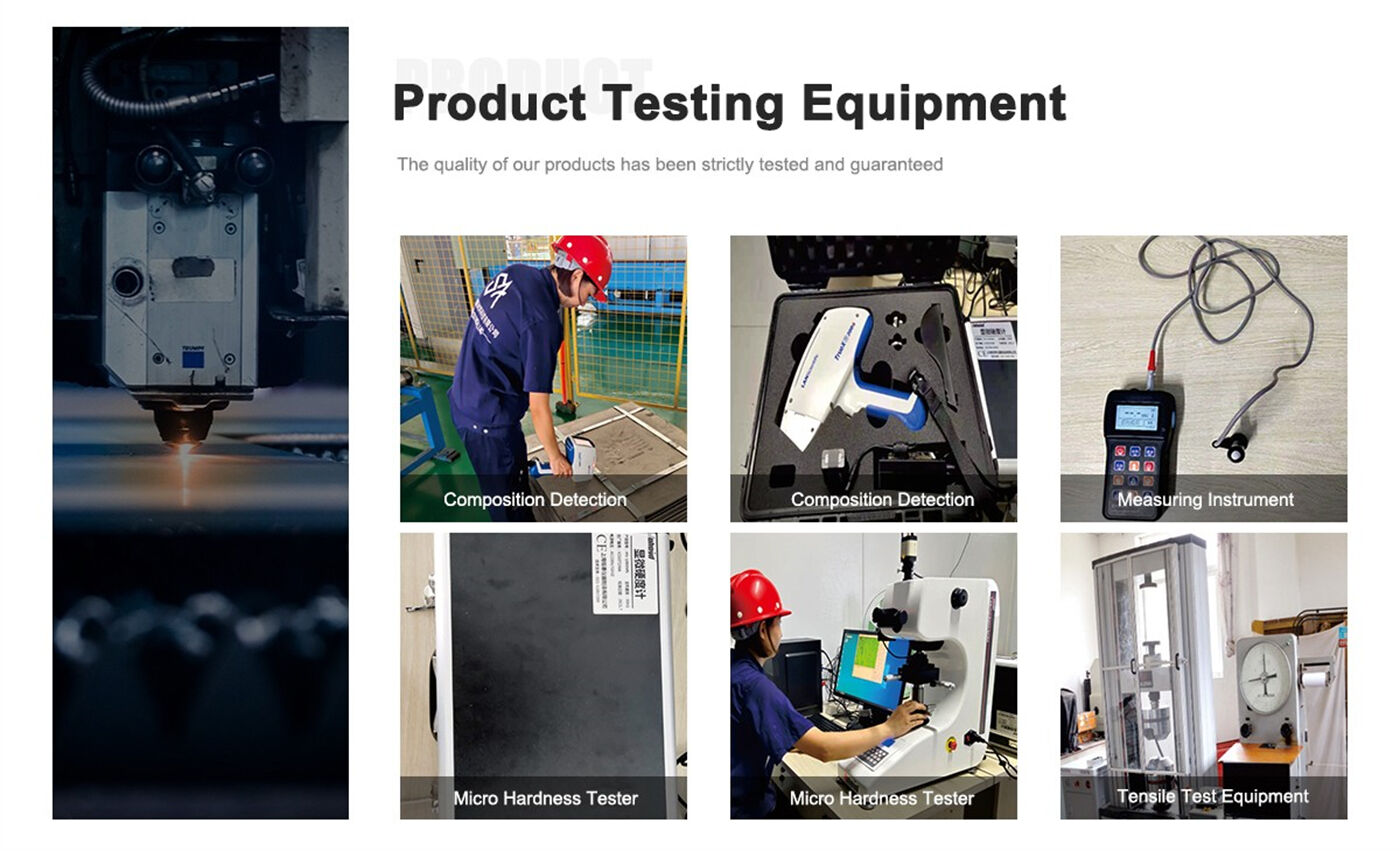

Сертифицированное премиальное качество – Соответствует стандартам AWS, ASTM и ISO отрасли.

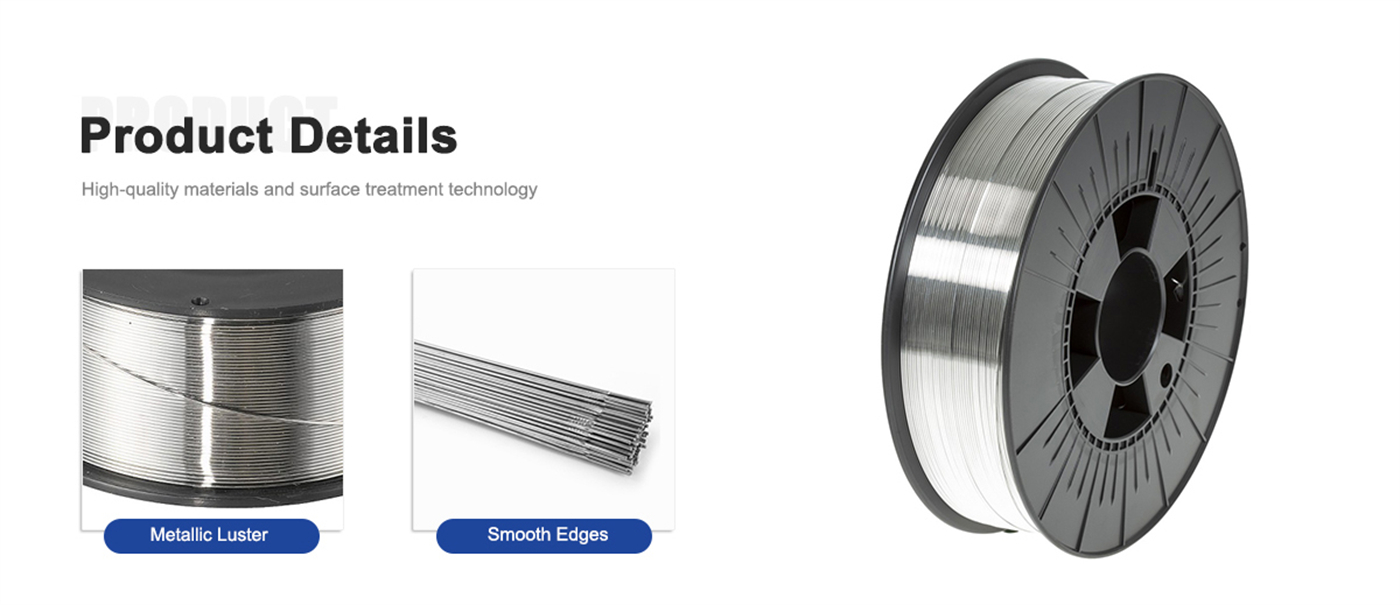

Пользовательские размеры и упаковка – Доступны в бобинах, катушках и вариантах резки по длине.

Быстрая и надежная международная доставка – Быстрая доставка клиентам во всем мире.

Надежная цепочка поставок – Обеспечивает постоянную доступность запасов для промышленного применения.

Закажите премиальную сварочную проволоку ERNiCrMo-4 (C-276) сегодня – Лучшие заводские цены!

Ищете высококачественную сварочную проволоку с гарантированной доступностью запасов? Свяжитесь с нами сегодня для оптовых цен, специальных скидок и быстрой доставки.

| Товар | ERNiCrMo-3 | ERNiCrMo-4 | ERNiCrMo-13 | ERNiCrFe-7 | ERNiCr-3 | ERNiCu-7 | ERCuNi | ERNi-1 |

| C | 0.1 | 0.02 | 0.01 | 0.04 | 0.1 | 0.15 | 0.03 | 0.15 |

| Mn | 0.05 | 1 | 0.5 | 1 | 2.5-3.5 | 4 | 0.5-1.0 | 1 |

| Фэ | 5 | 4-7 | 1.5 | 7-11 | 3 | 2.5 | 0.65 | 1 |

| P | 0.02 | 0.04 | 0.015 | 0.02 | 0.03 | 0.02 | 0.01 | 0.03 |

| С | 0.015 | 0.03 | 0.005 | 0.015 | 0.015 | 0.015 | 0.01 | 0.015 |

| Да, да. | 0.05 | 0.08 | 0.1 | 0.5 | 0.5 | 1.25 | 0.15 | 0.75 |

| Мд | 0.5 | 0.5 | Н/Д | 0.3 | 0.5 | отдых | отдых | 0.25 |

| Ни | ≥58 | отдых | отдых | отдых | ≥67 | 62-69 | 30-32 | ≥93 |

| С | Н/Д | 2.5 | 0.3 | Н/Д | Н/Д | Н/Д | Н/Д | Н/Д |

| АЛ | 0.4 | Н/Д | 0.1-0.4 | 1.1 | Н/Д | 1.25 | 0.15 | 1.5 |

| Ti | 0.4 | Н/Д | Н/Д | 1 | 0.75 | 1.5-3 | 0.5 | 2-3.5 |

| Кр | 20-23 | 14.5-16.5 | 22-24 | 28.5-31 | 18.0-22.0 | Н/Д | Н/Д | Н/Д |

| Nb+Ta | 3.5-4.15 | Н/Д | 1.8-2.5 | 0.01 | 2.0-3.0 | Н/Д | Н/Д | Н/Д |

| Мо | 8.0-10 | 15-17 | 15-16 | 0.5 | Н/Д | Н/Д | Н/Д | Н/Д |

| В | Н/Д | 0.35 | Н/Д | Н/Д | Н/Д | Н/Д | Н/Д | Н/Д |

| В | Н/Д | 3.0-4.5 | Н/Д | Н/Д | Н/Д | Н/Д | Н/Д | Н/Д |

| Отдых | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 |

| Присадочная проволока для сварки никеля и сплавов никеля | |

| Модель продукта (AWS) | Применение |

| ERNiCr-3 | Для сварки сплавов 600, 601 и 800 между собой, а также для сварки различных сталей между нержавеющей сталью и углеродистой сталью ERNiCrFe-7; Для сварки сплавов Inconel в рамках ASTM B163, 166, 167 и 168 |

| ERNiCrFe-6 | Для сварки стали с инконелем, сварки стали с нержавеющей сталью и никелевыми сплавами |

| ERNiCrCoMo-1 | Гетерогенная сварка для соединения никелевых хромовых кобальтовых молибденовых сплавов и различных супeralloys |

| ERNiCrMo-3 | Используется для сварки никелевых сплавов, углеродистой стали, нержавеющей стали и низколегированной стали,主要用于 сварки сплавов 625, 601, 802 и сварки сплавов на основе 9% никеля |

| ERNi-CI | Промышленное чистое никелевое наплавочное покрытие для сварки ковкого и серого чугуна |

| ERCuNi | Для сварки сплавов меди-никеля 70/30, 80/20, 90/10 |

| ERNiCu-7 | Для сварки никелевых сплавов меди B127, 163, 164 и 165 и др. |

| ERNi-1 | Для сварки чистых никелевых отливок и ковковых изделий, таких как сплавы в рамках ASTM B160, 161, 162, 163 |

| ERNiFeMn-CI | Для сварки шарового чугуна, dúctile чугуна, ковкого чугуна и серого чугуна между собой или с нержавеющей сталью, углеродистой сталью, низколегированной сталью и различными никелевыми сплавами |

| ERNiCrMo-4 | Для сварки никелевых хромоникелемоносодержащих сплавов между собой или для соединения никелевых хромоникелемоносодержащих сплавов с сталю́ и большинством других никелевых сплавов |

| ERNiCrMo-11 | Используется для сварки никелевых хромоникелемоносодержащих сплавов между собой или для соединения никелевых хромоникелемоносодержащих сплавов с сталю и большинством других никелевых сплавов, а также может применяться для наплавочной сварки шва из никелевых хромоникелемоносодержащих сплавов и стали |

| ERNiCrMo-13 | Для сварки низкоуглеродистых никелевых хромоникелемоносодержащих сплавов |