Трубы из никелевого сплава Hastelloy B-3 – Прочный и высокоэффективный материал

Мы предлагаем заводские цены и специальные скидки для оптовых заказов. Независимо от того, нужны вам небольшие или крупные партии, наши продукты доставляются быстро, чтобы обеспечить надежное снабжение промышленных проектов по всему миру.

- Обзор

- Характеристики

- Применения

- Часто задаваемые вопросы

- Рекомендуемые продукты

-

Отличная коррозионная стойкость: Выдающаяся производительность в высоко кислотных средах, включая соляную, серную и фосфорную кислоты.

-

Превосходная термическая устойчивость: Сохраняет прочность и коррозионную стойкость при повышенных температурах.

-

Высокая механическая прочность: Обеспечивает долговечность и сопротивление растрескиванию под высоким напряжением.

-

Улучшенная обрабатываемость: Позволяет эффективно выполнять формовку, обработку и сварку без значительного выпадения карбидов.

-

Химическая перерабатывающая промышленность: Используется в теплообменниках, трубопроводных системах, сосудах под давлением и реакторах для обработки коррозионных химикатов.

-

Авиакосмическая и оборонная промышленность: Необходима для высокопроизводительных конструкционных элементов, подвергаемых экстремальным условиям.

-

Морская и шельфовая инженерия: Идеальна для применения в трубах, устойчивых к морской воде.

-

Фармацевтическая и биотехнологическая промышленность: Используется в стерильном оборудовании для обработки, требующем высокой коррозионной стойкости.

-

Энергия и выработка электроэнергии: Применяется в ядерной, геотермальной и нефтехимической отраслях, где требуется высокопрочная, коррозионностойкая труба.

-

UNS Number: N10675

-

Стандарты ASTM: ASTM B622, ASTM B619 (Трубы без шва и сварные)

-

EN/DIN эквивалент: 2.4600

-

Плавление и сплавление: Производится с использованием вакуумно-индукционного плавления (VIM) или электродуговой печи (EAF) для поддержания чистоты.

-

Формирование труб (без шва или сварных): Обеспечивает оптимальные механические свойства и точность размеров.

-

Отжиг и термическая обработка: Улучшает коррозионную стойкость и повышает механическую устойчивость.

-

Завершающая обработка поверхности: Варианты включают кислотную очистку, пассивацию и полировку для оптимизации производительности.

-

Контроль качества: Включает оценку механических свойств, неразрушающий контроль (NDT) и измерительные проверки.

-

Различные размеры труб: Доступны разные диаметры, толщины стенок и длины для удовлетворения конкретных приложений.

-

Варианты поверхностной обработки: Яркий отжиг, без оксидного слоя или покрытый для усиления защиты.

-

Точная обработка и резка: обеспечение совместимости с различными промышленными процессами.

-

Соответствие международным стандартам: Соответствие ASTM, ASME и другим регулирующим сертификатам.

Hastelloy B-3 является никелево-молибденовым сплавом, разработанным для превосходной устойчивости к сильно восстанавливающим средам, таким как соляная кислота и другие агрессивные химические вещества. При изготовлении в виде труб этот сплав обеспечивает отличную механическую прочность, коррозионную стойкость и термальную устойчивость, что делает его идеальным для высокопроизводительных промышленных приложений.

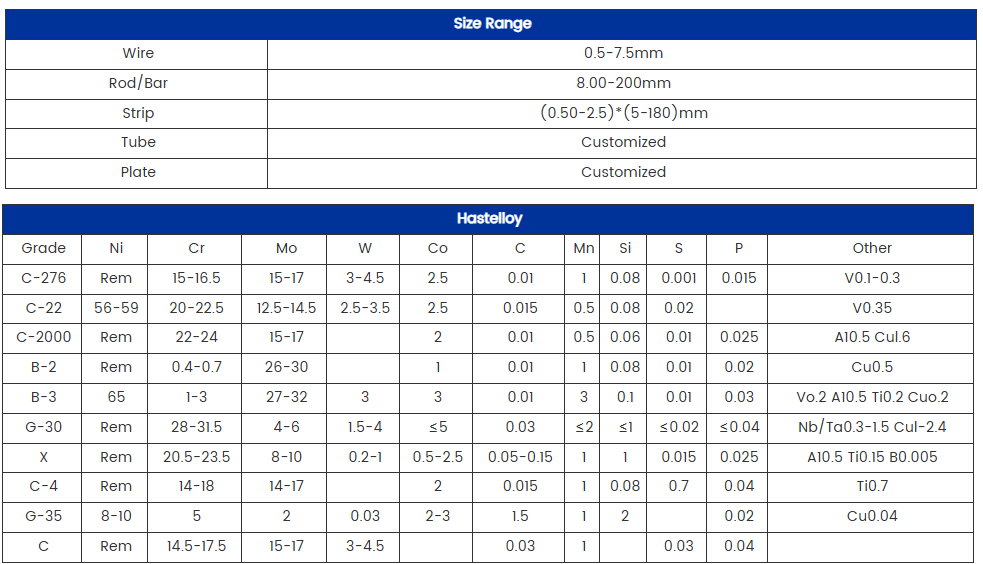

Состав материала и свойства

Трубы из Hastelloy B-3 состоят в основном из никеля и молибдена, с улучшенной устойчивостью к химическому воздействию. Основные характеристики включают:

Применение труб Hastelloy B-3

Благодаря отличной устойчивости к агрессивным химическим веществам и высокой прочности, трубы Hastelloy B-3 широко используются в:

Марки и стандарты

Трубы из Hastelloy B-3 соответствуют международным стандартам качества и производительности, включая:

Процесс производства

Производство труб из Hastelloy B-3 проходит строгий контроль качества для обеспечения точности и производительности:

Требования пользователей и настройка

Отрасли, использующие трубы из Hastelloy B-3, часто требуют специальных настроек для соответствия операционным потребностям. К ним относятся:

Часто задаваемые вопросы:

Сколько времени требуется для доставки?

Это зависит от количества заказа, 10-30 дней для малых заказов. Для крупных заказов требуется 60 дней.

Принимаете ли вы производство OEM/ODM?

Да! Мы принимаем производство OEM/ODM. Вы можете отправить нам свои образцы или чертежи.

Как вы контролируете качество своей продукции? Соответствуют ли химические свойства продукции стандартам качества?

С профессиональной командой по качеству, передовым планом планирования качества продукции, строгим исполнением и непрерывным улучшением, мы выдаем сертификаты проверки качества продукции, включая отчет о химическом анализе.

Может ли ваша компания предоставить подробные технические данные и чертежи?

Да, может. Пожалуйста, сообщите нам о необходимых продуктах и их применении, и мы отправим вам подробные технические данные и чертежи для оценки и подтверждения.

Как вы обрабатываете предпродажное и послепродажное обслуживание?

У нас есть профессиональная коммерческая команда, которая будет работать один на один, чтобы обеспечить ваши потребности в продуктах, и если у вас возникнут вопросы, он сможет ответить на них для вас!

Могу ли я посетить ваш завод перед размещением заказа?

Да, вы всегда можете посетить наш завод. Мы рады иметь возможность познакомиться поближе.

Где находится ваше производственное предприятие?

Мы производим свою продукцию в провинции Цзянсу, Китай, и отправляем её из Китая в вашу страну как можно скорее, что обычно зависит от ваших требований к продукции и количества.

Вы можете прислать образцы?

Да, мы можем.