N4 Чистый никелевый лист по заводской цене | Промышленное применение и крупные заказы

Мы предлагаем заводские цены и специальные скидки для оптовых заказов. Независимо от того, нужны вам небольшие или крупные партии, наши продукты доставляются быстро, чтобы обеспечить надежное снабжение промышленных проектов по всему миру.

- Обзор

- Характеристики

- Применения

- Часто задаваемые вопросы

- Рекомендуемые продукты

Введение в ленту из чистого никеля N4

Лента из чистого никеля N4 — это материал с высокой степенью чистоты (≥99.5% Ni), известный своим отличным сопротивлением коррозии, высокой электрической и тепловой проводимостью, а также превосходной механической прочностью. Эта никелевая лента широко используется в промышленном производстве, соединениях батарей, электрических компонентах и химической переработке.

Как поставщик напрямую от завода, мы предлагаем индивидуальные размеры, скидки при крупных закупках и обработку по программе OEM, обеспечивая экономически эффективные и высокоэффективные решения для различных промышленных применений.

Основные характеристики ленты из чистого никеля N4

✔ Высокая чистота никеля (≥99.5%) — гарантирует исключительную проводимость и сопротивление коррозии.

✔ Отличная электрическая и тепловая проводимость — идеально подходит для сварки батарей, электрических контактов и приложений передачи тепла.

✔ Превосходная коррозионная и окислительная стойкость – Хорошо работает в кислотных, щелочных и высокотемпературных средах.

✔ Высокая прочность и пластичность – Позволяет легкую обработку, гибку и сварку.

✔ Прямая поставка с завода – Доступны нестандартные размеры и скидки при оптовых закупках.

Применение полосы из чистого никеля N4

1. Производство батарей и накопление энергии

Используется для соединителей, выводов и табов в литий-ионных, никель-металлогидридных и щелочных батареях.

Обеспечивает низкое электрическое сопротивление и высокую проводимость для эффективной передачи мощности.

Необходим для сборки блока аккумуляторов в электромобилях, электроинструментах и потребительской электронике.

2. Электрические и электронные компоненты

Используется в электрических контактах, проводящих шинах и экранировании ЭМИ.

Обеспечивает стабильную электрическую производительность при высоких температурах.

Идеально подходит для применения в полупроводниковой и микроэлектронной промышленности.

3. Промышленное и химическое оборудование

Устойчив к кислотным и щелочным средам, что делает его подходящим для химических заводов, теплообменников и систем фильтрации.

Используется в морской, авиакосмической и атомной промышленности благодаря высокой коррозионной стойкости.

4. Точная сварка и металлообработка

Идеально подходит для точечной сварки, TIG-сварки и MIG-сварки.

Используется для высокопроизводительной промышленной сварки и соединения никелевых сплавов.

Почему стоит выбрать нашу чистую никелевую ленту N4?

Прямая продажа с завода – лучшие оптовые цены

Доступны индивидуальные размеры и обработка по программе OEM

Гарантированная высокая чистота и производительность

Быстрая международная доставка для оптовых заказов

Часто задаваемые вопросы:

Сколько времени требуется для доставки?

Это зависит от количества заказа, 10-30 дней для малых заказов. Для крупных заказов требуется 60 дней.

Принимаете ли вы производство OEM/ODM?

Да! Мы принимаем производство OEM/ODM. Вы можете отправить нам свои образцы или чертежи.

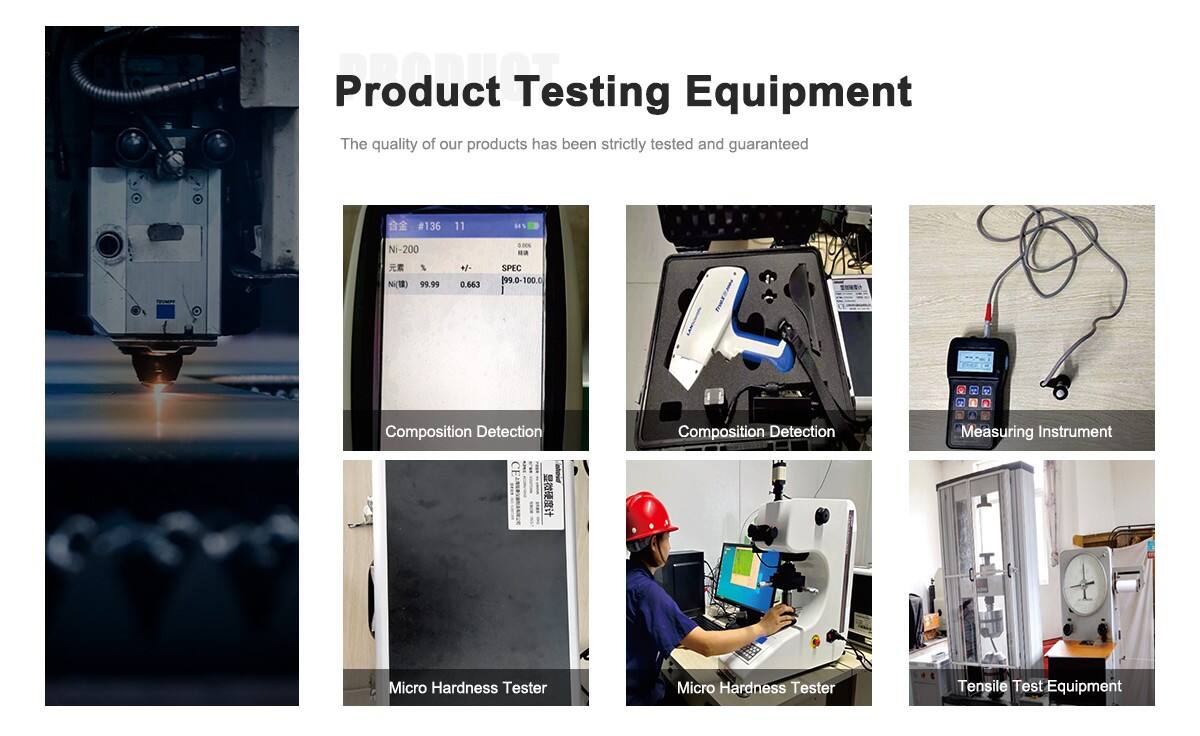

Как вы контролируете качество своей продукции? Соответствуют ли химические свойства продукции стандартам качества?

С профессиональной командой по качеству, передовым планом планирования качества продукции, строгим исполнением и непрерывным улучшением, мы выдаем сертификаты проверки качества продукции, включая отчет о химическом анализе.

Может ли ваша компания предоставить подробные технические данные и чертежи?

Да, может. Пожалуйста, сообщите нам о необходимых продуктах и их применении, и мы отправим вам подробные технические данные и чертежи для оценки и подтверждения.

Как вы обрабатываете предпродажное и послепродажное обслуживание?

У нас есть профессиональная коммерческая команда, которая будет работать один на один, чтобы обеспечить ваши потребности в продуктах, и если у вас возникнут вопросы, он сможет ответить на них для вас!

Могу ли я посетить ваш завод перед размещением заказа?

Да, вы всегда можете посетить наш завод. Мы рады иметь возможность познакомиться поближе.

Где находится ваше производственное предприятие?

Мы производим свою продукцию в провинции Цзянсу, Китай, и отправляем её из Китая в вашу страну как можно скорее, что обычно зависит от ваших требований к продукции и количества.

Вы можете прислать образцы?

Да, мы можем.