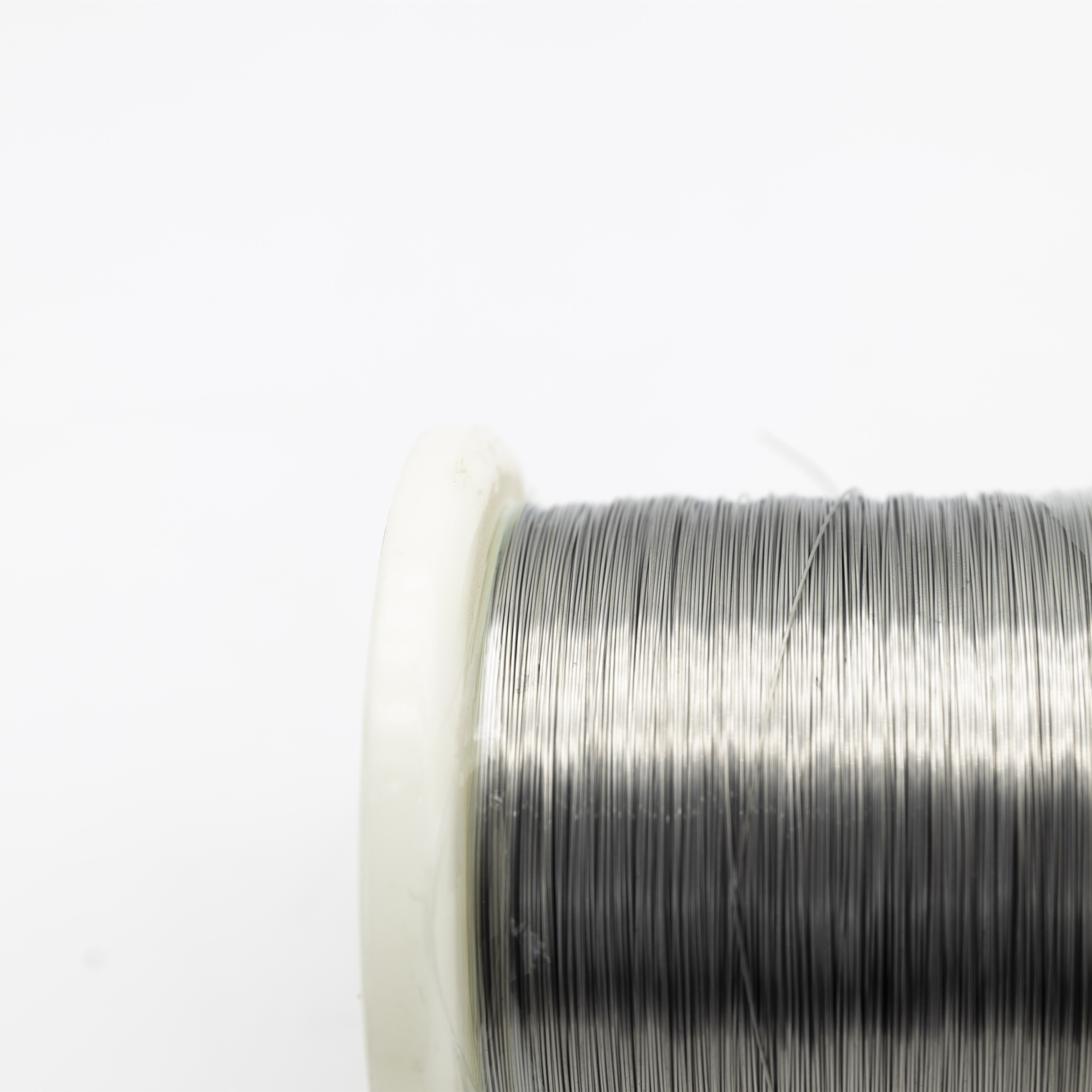

Пользовательская проволока Incoloy 925 – устойчива к коррозии и имеет длительный срок службы

Мы предлагаем заводские цены и специальные скидки для оптовых заказов. Независимо от того, нужны вам небольшие или крупные партии, наши продукты доставляются быстро, чтобы обеспечить надежное снабжение промышленных проектов по всему миру.

- Обзор

- Характеристики

- Применения

- Часто задаваемые вопросы

- Рекомендуемые продукты

Введение в провод Incoloy 925

Incoloy 925 является высокопроизводительным никелевым сплавом, разработанным для превосходной устойчивости к коррозии, высокой прочности и отличной долговечности. Основные компоненты сплава – никель, железо и хром, а также дополнительные элементы: молибден, титан, медь и алюминий, что обеспечивает отличные механические свойства и сопротивляемость жестким условиям окружающей среды.

Провод Incoloy 925 широко применяется в промышленных решениях, где важны высокая прочность и устойчивость к коррозии, включая морскую, авиакосмическую и нефтегазовую отрасли. Его выдающаяся сопротивляемость точечной коррозии, щелевой коррозии и коррозионному растрескиванию под напряжением делает его идеальным для сложных условий эксплуатации.

Основные характеристики провода Incoloy 925

Исключительная коррозионная стойкость: Выдерживает агрессивные среды, включая морскую воду, кислотные растворы и окисление при высоких температурах.

Высокая прочность и вязкость: Обеспечивает превосходную механическую прочность, что делает ее подходящей для тяжелых условий эксплуатации.

Долгий срок службы: Разработана с учетом долговечности, гарантирующей длительную работу в экстремальных условиях.

Отличная свариваемость и обрабатываемость: Легко обрабатывается в различные диаметры проволоки и произвольные формы.

Превосходная устойчивость к коррозионному растрескиванию под напряжением: Идеальна для сред с высоким давлением и высокими температурами.

Применение проволоки Инколой 925

Благодаря своим выдающимся материалам, проволока Инколой 925 используется в различных отраслях, включая:

1. Нефтяная и газовая промышленность

Буровые компоненты: Используются в колонках труб и оборудовании на устье скважины.

Сетка и фильтры: Необходимы для процессов фильтрации и разделения.

Противокоррозионный провод: Используется в подводных трубопроводах и морских сооружениях.

2. Морская инженерия

Провод, устойчивый к морской воде: Подходит для судостроения и морских платформ.

Структурное армирование: Используется в системах буксировки и глубоководных приложениях.

3. Аэрокосмическая промышленность

Провод высокой температуры: Используется в реактивных двигателях и системах выхлопа.

Структурные крепежные элементы и пружины: Обеспечивают прочность в экстремальных условиях полета.

4. Химическая переработка

Компоненты теплообменников: Подходят для использования в коррозийных химических средах.

Промышленные нагревательные элементы: Используются в печах и системах процессного нагрева.

Процесс производства провода Incoloy 925

Выбор сырья: Для оптимальной производительности выбираются высокочистые никель, железо, хром и другие легирующие элементы.

Плавка и очистка: Сплав плавится с использованием передовых методов вакуумно-индукционной плавки (VIM) или электродуговой печи (EAF).

Прямоугольная вытяжка и формование: Материал обрабатывается до проволочной формы с помощью точных технологий вытяжки проволоки.

Термическая обработка и отжиг: Улучшает механические свойства и коррозионную стойкость.

Завершающая обработка поверхности и контроль качества: Включает полирование, травление и строгие испытания для соответствия отраслевым стандартам.

Почему стоит выбрать индивидуальную проволоку Incoloy 925?

Прямая поставка с завода – конкурентоспособные цены

Доступны индивидуальные размеры и спецификации

Соответствует стандартам ASTM, ASME и другим международным стандартам

Доказанная эффективность в суровых промышленных условиях

Заключение

Проволока из сплава Incoloy 925 является идеальным выбором для отраслей, требующих высокой прочности, коррозионной стойкости и длительного срока службы. Будь то морские, нефтяные и газовые или авиакосмические приложения, этот никелевый сплав обеспечивает надежность и производительность в экстремальных условиях.

Часто задаваемые вопросы:

Сколько времени требуется для доставки?

Это зависит от количества заказа, 10-30 дней для малых заказов. Для крупных заказов требуется 60 дней.

Принимаете ли вы производство OEM/ODM?

Да! Мы принимаем производство OEM/ODM. Вы можете отправить нам свои образцы или чертежи.

Как вы контролируете качество своей продукции? Соответствуют ли химические свойства продукции стандартам качества?

С профессиональной командой по качеству, передовым планом планирования качества продукции, строгим исполнением и непрерывным улучшением, мы выдаем сертификаты проверки качества продукции, включая отчет о химическом анализе.

Может ли ваша компания предоставить подробные технические данные и чертежи?

Да, может. Пожалуйста, сообщите нам о необходимых продуктах и их применении, и мы отправим вам подробные технические данные и чертежи для оценки и подтверждения.

Как вы обрабатываете предпродажное и послепродажное обслуживание?

У нас есть профессиональная коммерческая команда, которая будет работать один на один, чтобы обеспечить ваши потребности в продуктах, и если у вас возникнут вопросы, он сможет ответить на них для вас!

Могу ли я посетить ваш завод перед размещением заказа?

Да, вы всегда можете посетить наш завод. Мы рады иметь возможность познакомиться поближе.

Где находится ваше производственное предприятие?

Мы производим свою продукцию в провинции Цзянсу, Китай, и отправляем её из Китая в вашу страну как можно скорее, что обычно зависит от ваших требований к продукции и количества.

Вы можете прислать образцы?

Да, мы можем.