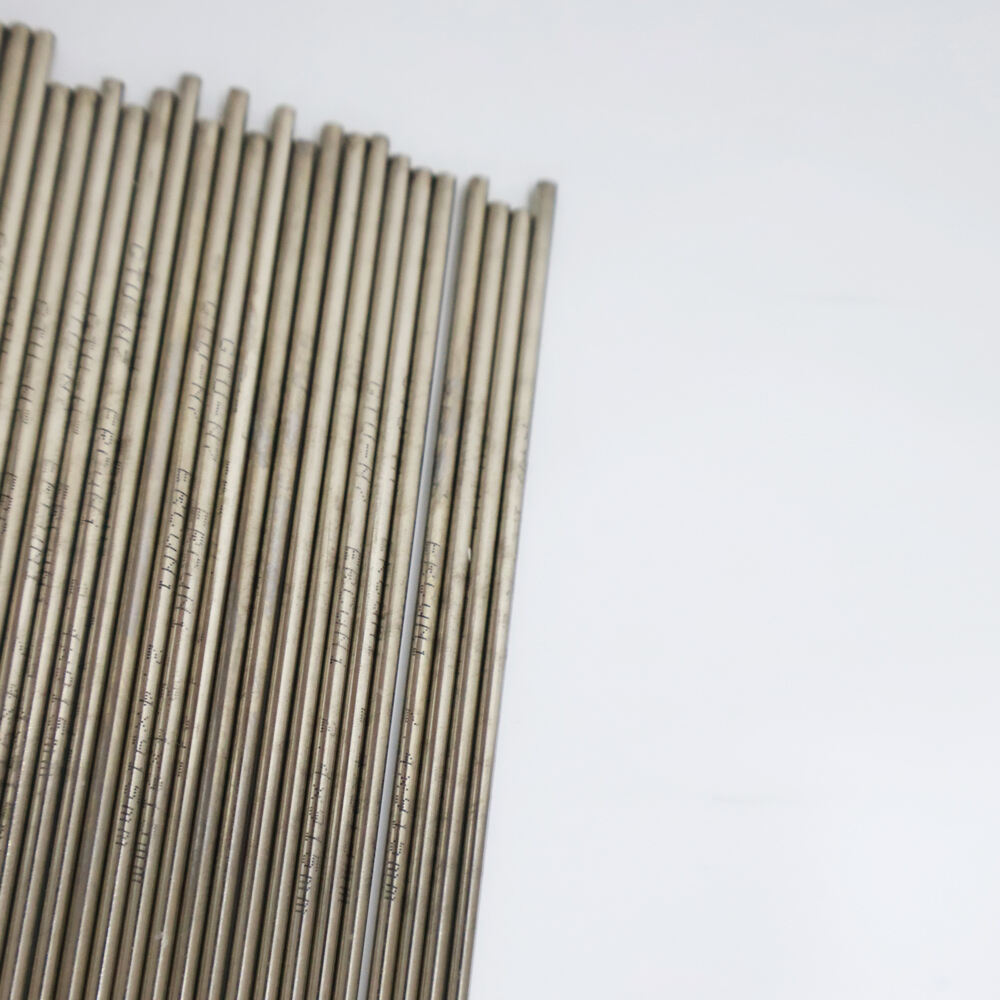

Alambre Monel K500 Personalizado – Fabricación de Precisión y Envío Rápido

Ofrecemos precios directos de fábrica y descuentos especiales para pedidos por mayor. Ya sea que necesites cantidades pequeñas o grandes, nuestros productos se envían rápidamente para garantizar un suministro confiable para proyectos industriales en todo el mundo.

- Descripción general

- Especificación

- Aplicaciones

- Preguntas frecuentes

- Productos recomendados

Alta resistencia y dureza debido al endurecimiento por precipitación

Excelente resistencia a la corrosión en agua salada, ácidos y ambientes alcalinos

No magnético en condiciones recocidas

Buena resistencia a la fatiga y a la temperatura

Apto para aplicaciones en temperaturas extremas

Marina & Offshore: Se utiliza en cables, sujetadores y resortes para entornos marinos agresivos

Aeroespacial: Se emplea en componentes críticos de aeronaves debido a su resistencia y capacidad térmica

Petróleo & Gas: Ideal para componentes subterráneos, ejes de bombas y ajustes de válvulas

Procesamiento Químico: Adecuado para intercambiadores de calor, bombas y sistemas de tuberías en entornos corrosivos

Industria Médica: Se utiliza en instrumentos quirúrgicos y dispositivos médicos implantables

ASTM B865

AMS 4676

UNS N05500

DIN 2.4375

Alambre redondo

Cable plano

Alambre cuadrado

Diámetros y longitudes personalizados disponibles bajo solicitud

Fusión y Aleación: Los materiales básicos se funden y alean para obtener la composición química correcta.

Trabajo en Caliente y Frío: La aleación pasa por procesos de laminación, estirado o extrusión para formar alambre con las dimensiones deseadas.

Tratamiento Térmico: El endurecimiento por precipitación mejora la resistencia y las propiedades mecánicas.

Tratamiento y Acabado de Superficie: Procesos como el desescamado, pulido y recubrimiento mejoran la resistencia a la corrosión y la calidad superficial.

Control de Calidad: Inspecciones estrictas, incluidas pruebas de tracción, medición de dureza y verificación de resistencia a la corrosión, garantizan el cumplimiento con las especificaciones.

Fabricación de Precisión: Tamaños, formas y tolerancias personalizadas para alambres

Envío Rápido: Tiempos de entrega rápidos para cumplir con plazos de proyectos urgentes

Certificación de Materiales: Total trazabilidad con informes de prueba de fábrica (MTR) y cumplimiento con estándares de la industria

Soporte Técnico: Asesoramiento experto en selección y aplicación de materiales

Monel K500 es una aleación de níquel-cobre de alto rendimiento conocida por su excelente resistencia, resistencia a la corrosión y propiedades mecánicas sobresalientes. Combina la excepcional resistencia a la corrosión del Monel 400 con un aumento en la dureza y la resistencia, lo que la convierte en una elección ideal para aplicaciones exigentes. El alambre personalizado de Monel K500 se fabrica específicamente para cumplir con especificaciones precisas y está disponible con envío rápido para garantizar la finalización oportuna del proyecto.

Resumen del Material

Monel K500 (UNS N05500) es una versión endurecida por precipitación de Monel 400, con adiciones de aluminio y titanio para mejorar la resistencia y la dureza. Esta aleación mantiene una excelente resistencia a la corrosión en entornos marinos y químicos mientras proporciona un rendimiento mecánico mejorado.

Propiedades clave:

Aplicaciones del alambre Monel K500

El alambre Monel K500 personalizado se utiliza ampliamente en industrias que requieren una excelente resistencia a la corrosión y alta resistencia. Algunas aplicaciones comunes incluyen:

Grados y Especificaciones Disponibles

El alambre Monel K500 está disponible en varios grados y formas para satisfacer las necesidades de diferentes industrias.

Estándares y Especificaciones Comunes:

Formas y tamaños de alambre:

Proceso de fabricación

La fabricación con precisión garantiza la más alta calidad y rendimiento del alambre de Monel K500. El proceso de producción generalmente incluye:

Satisfacción de las necesidades del cliente

En [Your Company Name], proporcionamos soluciones personalizadas de alambre Monel K500 adaptadas a aplicaciones específicas. Nuestros servicios incluyen:

¿Qué es eso?

¿Cuánto tiempo dura la entrega?

Depende de la cantidad del pedido, 10-30 días para pedidos pequeños. Para pedidos grandes, tarda 60 días.

¿Aceptan producción OEM/ODM?

¡Sí! Aceptamos producción OEM/ODM. Puedes enviarnos tus muestras o dibujos.

¿Cómo controlan la calidad de sus productos? ¿Las propiedades químicas de los productos cumplen con los estándares de calidad?

Con un equipo de calidad profesional, planificación avanzada de la calidad del producto, implementación estricta y mejora continua, emitiremos un certificado de inspección de calidad del producto, incluido el informe de análisis químico.

¿Puede su empresa proporcionar datos técnicos detallados y dibujos?

Sí, puedes. Por favor, dinos los productos y aplicaciones que necesitas, y te enviaremos datos técnicos detallados y dibujos para tu evaluación y confirmación.

¿Cómo manejan el servicio antes y después de la venta?

Tenemos un equipo de negocios profesional que trabajará uno a uno para proteger tus necesidades de producto, y si tienes alguna pregunta, él puede responderlas por ti.

¿Puedo visitar tu fábrica antes de hacer un pedido?

Sí, eres bienvenido a visitar nuestra fábrica. Nos alegra tener la oportunidad de conocernos.

¿Dónde está tu base de producción?

Fabricamos nuestros productos en Jiangsu, China y los enviamos desde China a tu país lo antes posible, lo cual generalmente depende de los requisitos del producto y la cantidad.

¿Puede enviar muestras?

Sí, podemos hacerlo.