ERNiCrMo-4 (C-276) Welding Wire – Direct Factory Supply, International Shipping

More:ERNiCrMo-3,ERNiCrMo-4,ERNiCrMo-13,ERNiCrFe-3,ERNiCrFe-7,ERNiCr-3,ERNiCr-7,ERNiCu-7,ERNi-1, ER70S-6.

We offer factory-direct pricing with special discounts on bulk orders. Whether you need small or large quantities, our ERNiCrMo-4 welding wire is available for immediate shipment, ensuring reliable supply for industrial projects worldwide.

- Overview

- Applications

- FAQs

- Recommended Products

Introduction to ERNiCrMo-4 (C-276) Welding Wire

ERNiCrMo-4 (C-276) welding wire is a high-performance nickel-based alloy designed for critical industrial welding applications. Also known as Hastelloy® C-276, this alloy provides exceptional corrosion resistance, superior weldability, and high-temperature strength, making it ideal for demanding environments such as chemical processing, oil & gas, power plants, and marine industries.

We offer direct factory supply with international shipping, ensuring that businesses worldwide receive top-quality ERNiCrMo-4 welding wire at competitive prices. With guaranteed stock availability, custom order options, and fast delivery, we are your trusted global supplier.

Material Overview: ERNiCrMo-4 (C-276) Welding Wire Properties

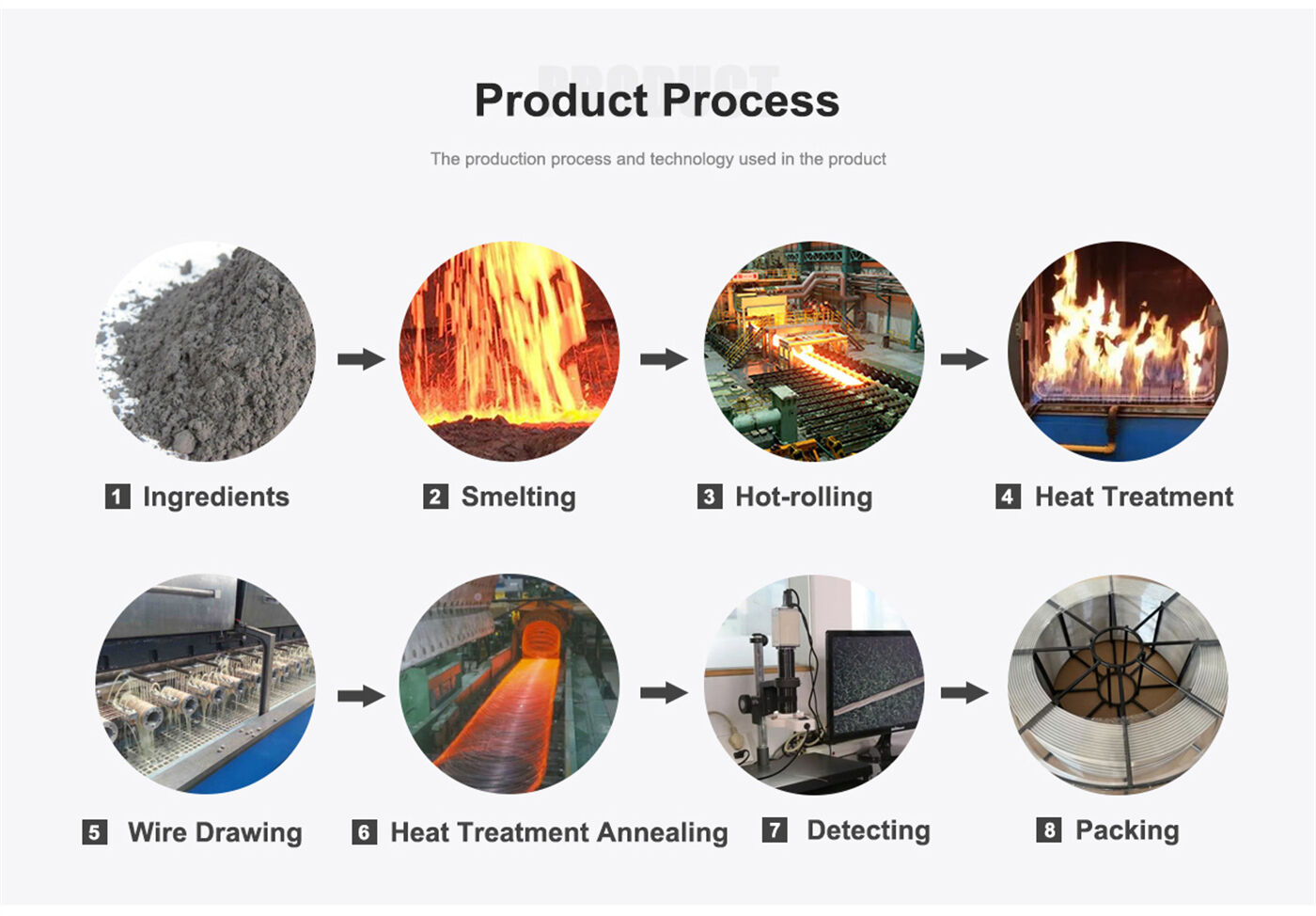

ERNiCrMo-4 (C-276) welding wire is manufactured from a nickel-chromium-molybdenum alloy with added iron and tungsten for enhanced performance. This alloy is highly resistant to oxidizing and reducing environments, making it an excellent choice for industries requiring durability, chemical resistance, and thermal stability.

Key Features of ERNiCrMo-4 (C-276) Welding Wire

✔ Superior Corrosion Resistance – Protects against pitting, crevice corrosion, and stress corrosion cracking in chloride-rich and highly acidic environments.

✔ High-Temperature Strength – Retains mechanical stability and oxidation resistance up to 1093°C (2000°F).

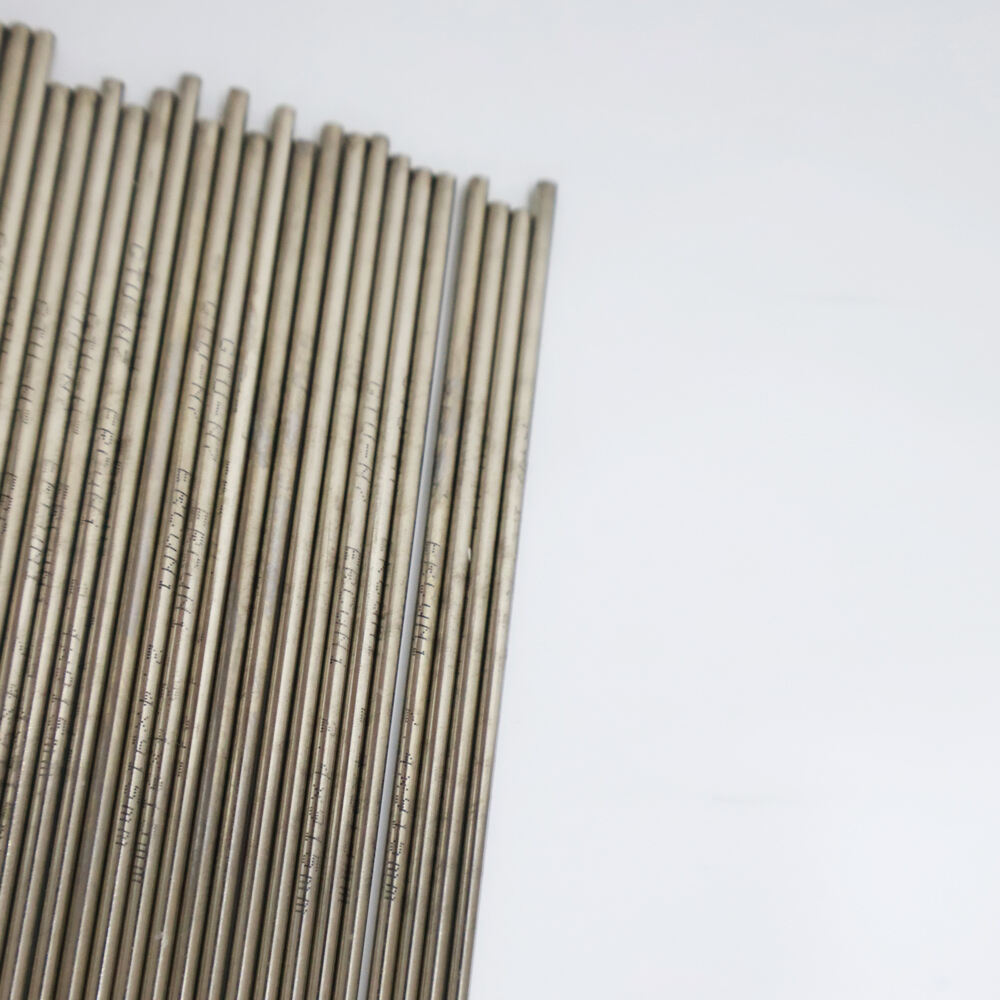

✔ Excellent Weldability – Ensures smooth, defect-free welds with minimal hot cracking and porosity.

✔ Chemical Resistance – Withstands exposure to hydrochloric, sulfuric, and nitric acids, as well as oxidizing and reducing agents.

✔ Durable and Long-Lasting – Provides extended service life in extreme industrial conditions.

With its proven reliability and performance, ERNiCrMo-4 welding wire is the preferred choice for welding C-276 alloy components and other corrosion-resistant materials.

Industry Standards & Specifications

Our ERNiCrMo-4 (C-276) welding wire is produced to strict global standards, ensuring superior quality and compatibility across multiple industries.

Standard Specification

AWS A5.14 ERNiCrMo-4

UNS Number N10276

ASTM Standard ASTM B574, ASTM B575

ISO Standard ISO 18274: NiCr15Mo16Fe6W4

These certifications guarantee that our welding wire meets the highest safety, performance, and durability standards.

Applications of ERNiCrMo-4 (C-276) Welding Wire

ERNiCrMo-4 welding wire is widely used in industries where extreme conditions demand strong, corrosion-resistant welds.

1. Chemical Processing Industry

Heat Exchangers & Reactors – Resists highly corrosive chemicals and extreme temperatures.

Storage Tanks & Pipelines – Provides durability against aggressive acids and industrial solvents.

Pumps & Valves – Prevents corrosion in fluid-handling systems.

2. Power Generation & Nuclear Industry

Boilers & Steam Turbines – Withstands high-temperature oxidation and thermal cycling.

Nuclear Reactor Components – Ensures radiation and heat resistance for long-term performance.

Heat Recovery Systems – Protects against material degradation under extreme heat and pressure.

3. Oil & Gas Industry

Offshore Drilling Rigs & Platforms – Provides resistance to sulfide stress cracking (SSC) and hydrogen embrittlement.

LNG Storage & Cryogenic Equipment – Maintains structural integrity under extreme temperature variations.

Petrochemical Refinery Processing Units – Ensures long-term performance in sulfur-rich environments.

4. Aerospace & Marine Engineering

Jet Engine Components – Offers high-temperature oxidation resistance for aviation applications.

Seawater Heat Exchangers – Prevents corrosion in marine environments.

Shipbuilding & Subsea Equipment – Provides durability in saltwater-exposed structures.

5. Pharmaceutical & Food Processing

Sanitary Piping & Heat Exchangers – Ensures hygienic and corrosion-resistant performance.

Sterilization Equipment – Withstands aggressive cleaning agents and high-temperature sterilization.

ERNiCrMo-4 welding wire is a critical material for ensuring long-lasting, high-quality welds in these demanding industries.

Why Choose Our ERNiCrMo-4 (C-276) Welding Wire?

✅ Direct Factory Supply – Get high-quality welding wire at manufacturer-direct prices.

✅ Global Shipping Available – Fast and reliable international delivery to meet your project needs.

✅ Certified High-Quality Alloy – Meets AWS, ASTM, and ISO industry standards.

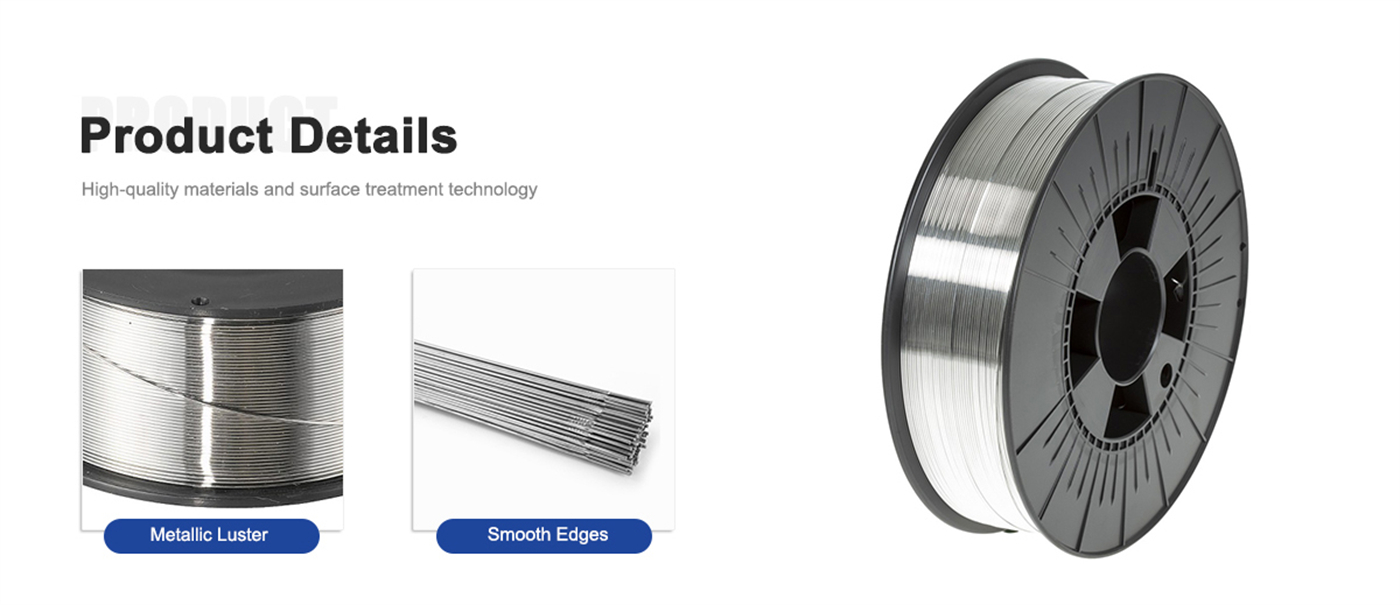

✅ Custom Sizes & Packaging – Available in spools, coils, and custom-cut lengths.

✅ Bulk & Wholesale Orders Welcome – Special discounts on large-volume purchases.

✅ Guaranteed Stock Availability – Always in stock for immediate dispatch.

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

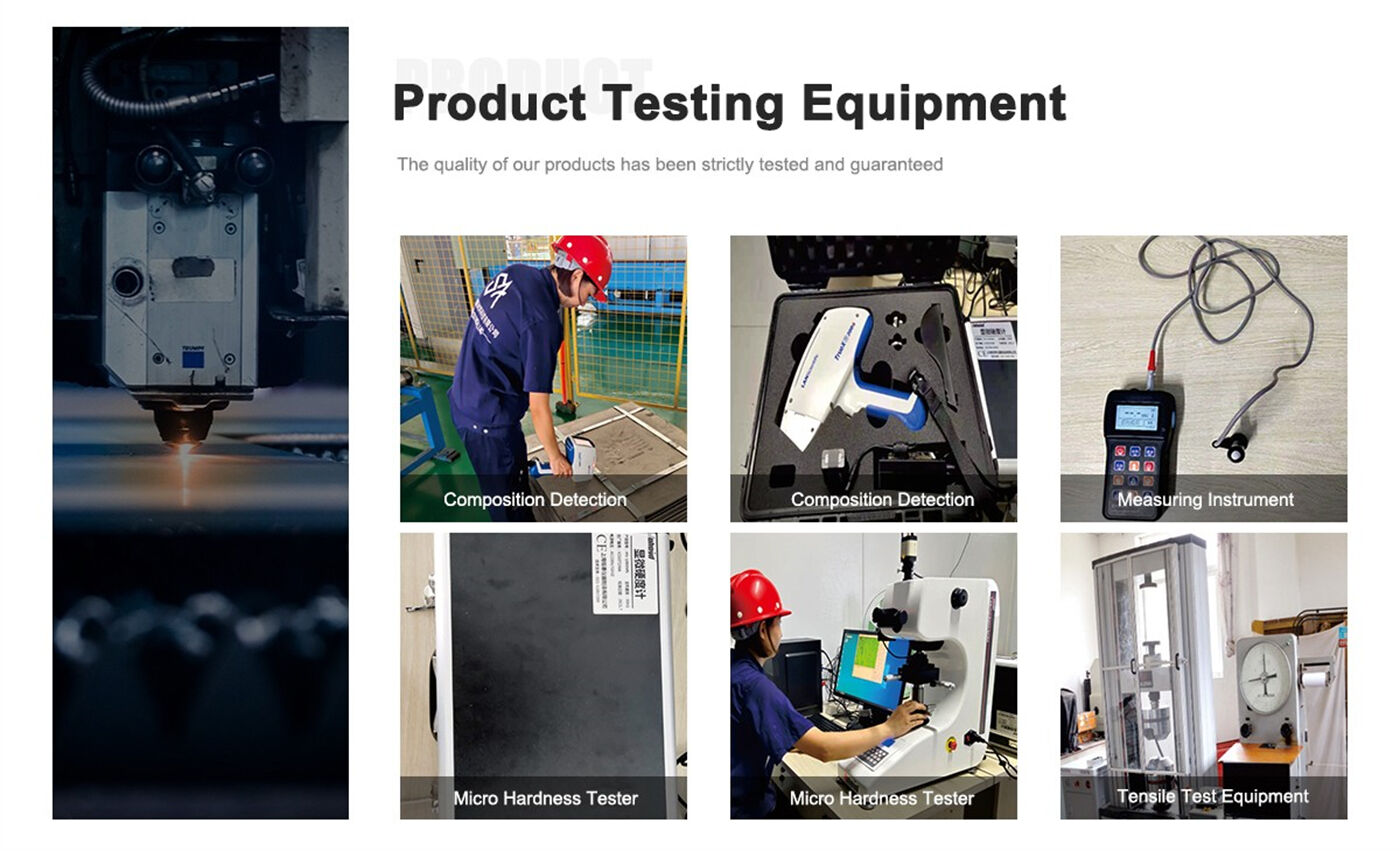

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.