Högstark Hastelloy C-22 Tråd – Precisionstillverkning & Snabb Leverans

Vi erbjuder direktpriser från fabriken och särskilda rabatter för bulkbeställningar. Oavsett om du behöver små eller stora mängder, skickas våra produkter snabbt för att säkerställa en pålitlig leverans för industriprojekt över hela världen.

- Översikt

- Specificitet

- Tillämpningar

- Frågor som ofta ställs

- Rekommenderade produkter

- Används i flygmotor-komponenter och utsläppssystem på grund av dess motstånd mot värme och oxidation.

- Nödvändig i jetskruvar, bränsle-system och kritiska rymd- och flygstrukturer.

- Ideal för tillverkning av komponenter som exponeras för sura och oxidativa miljöer, såsom reaktorer, värmeväxlingar och rörledningsystem.

- Motstandsigt mot svavelsyra, hydroklor syra och klorbaserade kemikalier.

- Perfekt för marin kablage och offshore-strukturer som kräver extrem motståndighet mot sjövatten och saltinnehålliga miljöer.

- Används i djuphavsutforskning och tillverkning av marina utrustningar.

- Tillämpas i kärnreaktorer och fossila bränsle-kraftverk där motståndighet mot extrem värme och strålning krävs.

- Används i elektrisk kablage och högpresterande kopplingar.

- Används i medicinska implantat och kirurgiska instrument som kräver korrosionsmotståndighet och biokompatibilitet.

- Förstår för tillverkning av precisionselektroniska komponenter i medicinska enheter.

- Råmaterialen smälts i en vakuum eller elektrisk bågeugn för att uppnå den önskade kemiska sammansättningen.

- Legeringen vallas hettpressad till trådstavar och dras sedan till den krävda tråddiametern med hög precision.

- Lösningstuothärdning förbättrar korrosionsmotstånd och förstärker mekaniska egenskaper.

- Tråden går igenom polering, ettring eller elektroplåtering för en jämn yttillverkning.

- Icke-skadlig provning (NDT), dragfastighetsprovning och kemisk analys säkerställer följd av ASTM B574 normer.

- Ökande efterfrågan på värmebeständiga och högdragfasthetslegeringar för kritiska tillämpningar.

- Industrin föredrar anpassade tråddiameter, beläggningar och förpackning för specifika tillämpningar.

- Pålitliga leveranskedjor och direkttjänster från fabriken garanterar korta omloppsider.

- Konkurrenskraftiga priser för storskaliga industriella behov.

Hastelloy C-22-tråd är ett högstarkt, korrosionsbeständigt nikkelbaserat legeringsprodukt som utvecklats för krävande industriella tillämpningar. Den erbjuder utmärkt motstånd mot aggressiva kemiska miljöer, höga temperaturer och mekanisk spänning, vilket gör den till en idealisk val för industrier som rymd- och flygindustrin, kemiprocessnäringen och sjöfarten. Med precist tillverkning och snabb leverans uppfyller Hastelloy C-22-tråd de stränga kraven inom modern industriell tillämpning.

Vad är Hastelloy C-22?

Hastelloy C-22 (UNS N06022) är en nikelbaserad legering som innehåller molibden, krom och järn. Denna unika sammansättning ger utmärkt motstånd mot punktering, sprickkorrosion och spänningskorrosionsbrytning i extrem miljö, särskilt i oxidierande och sura förhållanden.

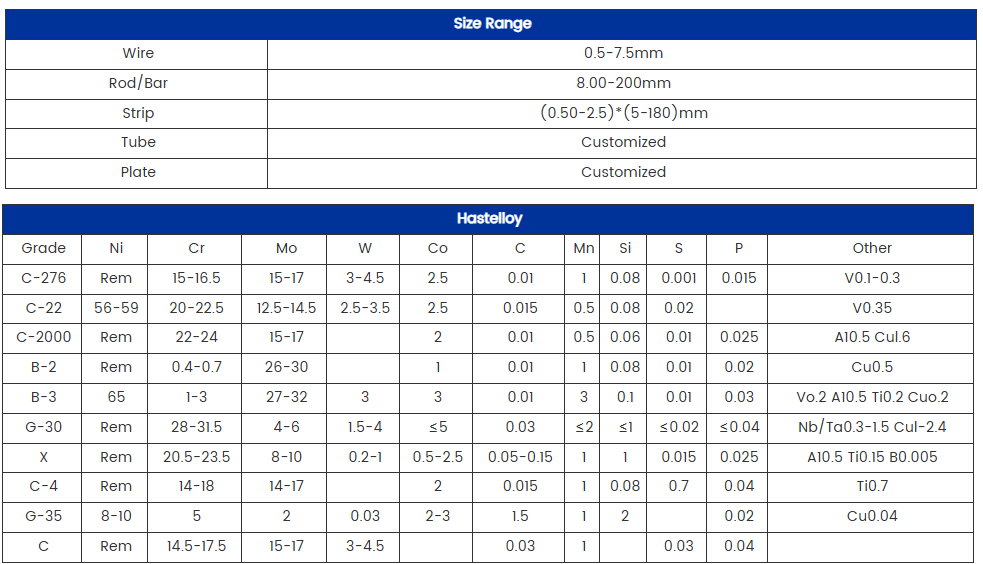

Kemisk sammansättning av Hastelloy C-22

| Element | Sammansättning (%) |

|---|---|

| Nickel (Ni) | Balans |

| Molybden (Mo) | 12,5 - 14,5 |

| Krom (Cr) | 20,0 - 22,5 |

| Järn (Fe) | 2,0 - 6,0 |

| Kobolt (Co) | ≤ 2,5 |

| Tungstén (W) | 2.5 - 3.5 |

| Kol (C) | ≤ 0,015 |

| Mangan (Mn) | ≤ 0,50 |

| Silikium (Si) | ≤ 0.08 |

| Fosfor (P) | ≤ 0.02 |

| Svavel (S) | ≤ 0.02 |

Användningar av Hastelloy C-22 Tråd

Tack vare sin utmärkta korrosionsmotståndighet, höga mekaniska egenskaper och termisk stabilitet används Hastelloy C-22-tråd i flera industrier:

1. Rymd- och flygindustrin

2. Kemiprocessindustrin

3. Marin & Offshore-användning

4. Elproduktion & Kärnenergi

5. Medicinsk & Farmaceutisk Utrustning

Tillverkningsprocess för Hastelloy C-22-tråd

Hastelloy C-22-tråd tillverkas under strikt kvalitetskontroll för att säkerställa hög styrka, hållbarhet och precision.

1. Smältning & Legering

2. Hettvalning & Dragning

3. Uthärdning & Värmebehandling

4. Ytbehandling & Beklädnad

5. Kvalitetsprovning

Användardemand & Marknadsutveckling

1. Ökande efterfrågan inom luftfart och energisektor

2. Anpassning och OEM-tjänster

3. Snabb leverans och global distribution

4. Kostnadseffektiva bulkorder

Frågor:

Hur lång leveranstid har ni?

Det beror på beställningsmängden, 10-30 dagar för små beställningar. För stora beställningar tar det 60 dagar.

Accepterar ni OEM/ODM-produktion?

Ja! Vi accepterar OEM/ODM-produktion. Du kan skicka oss dina prov eller ritningar.

Hur kontrollerar ni kvaliteten på era produkter? Möt kemiska egenskaper hos produkterna kvalitetsnormerna?

Med en professionell kvalitetsteam, avancerad produktkvalitetsplanering, strikt genomförande och kontinuerlig förbättring, kommer vi att utfärda produktkvalitetsintyg, inklusive kemisk analysrapport.

Kan er företag tillhandahålla detaljerade tekniska data och ritningar?

Ja, du kan. Berätta för oss vilka produkter och tillämpningar du behöver, och vi kommer att skicka dig detaljerade tekniska data och ritningar för din utvärdering och bekräftelse.

Hur hanterar ni försäljningstjänster och efterföljande service?

Vi har ett professionellt företagsteam som arbetar en till en för att skydda dina produktbehov, och om du har några frågor, kan han svara på dem för dig!

Kan jag besöka er fabrik innan jag gör en order?

Ja, du är välkommen att besöka vår fabrik. Vi är glada över möjligheten att komma åt varandra.

Var ligger din produktionsbas?

Vi tillverkar våra produkter i Jiangsu, Kina och skickar dem från Kina till ditt land så snabbt som möjligt, vilket vanligtvis beror på dina produktspecifikationer och kvantitet.

Kan du skicka prover?

- Ja, det kan vi.