Hastelloy B-2 Band – Fabriksproducerad precisionsalloy för olika industrier

Vi erbjuder direktpriser från fabriken och särskilda rabatter för bulkbeställningar. Oavsett om du behöver små eller stora mängder, skickas våra produkter snabbt för att säkerställa en pålitlig leverans för industriprojekt över hela världen.

- Översikt

- Specificitet

- Tillämpningar

- Frågor som ofta ställs

- Rekommenderade produkter

-

Utömordinaire korrosionsresistens: Mycket motståndskraftig mot hydroklor syra, svavelsyra och andra reducerande agenter.

-

Hög styrka och flexibilitet: Garanterar hållbarhet i krävande industriella miljöer.

-

Utmärkt svetsbarhet och formbarhet: Lämplig för formering, maskinbearbetning och svetsning utan betydande karbidprecipitation.

-

Superiör termisk stabilitet: Fungerar effektivt i högtemperatursapplikationer utan försämring.

-

Kemiprocessindustri: Används i värmeväxlare, lagringstankar, rörledningssystem och reaktorer som hanterar aggressiva kemikalier.

-

Rymd- och försvarsindustrin: Tillämpas i precisionskomponenter som utsätts för extrem miljö och korrosiva villkor.

-

Marin och offshore-teknik: Idealiskt för havsvattenresistenta strukturella tillämpningar.

-

Läkemedels- och bioteknikindustrin: Används i sterila utrustningar och kemiresistenta tillämpningar.

-

Energi- och kraftgenerering: Tillämpas i geotermala, kärnkrafts- och petrokemiska industrier där korrosionsresistenta material krävs.

-

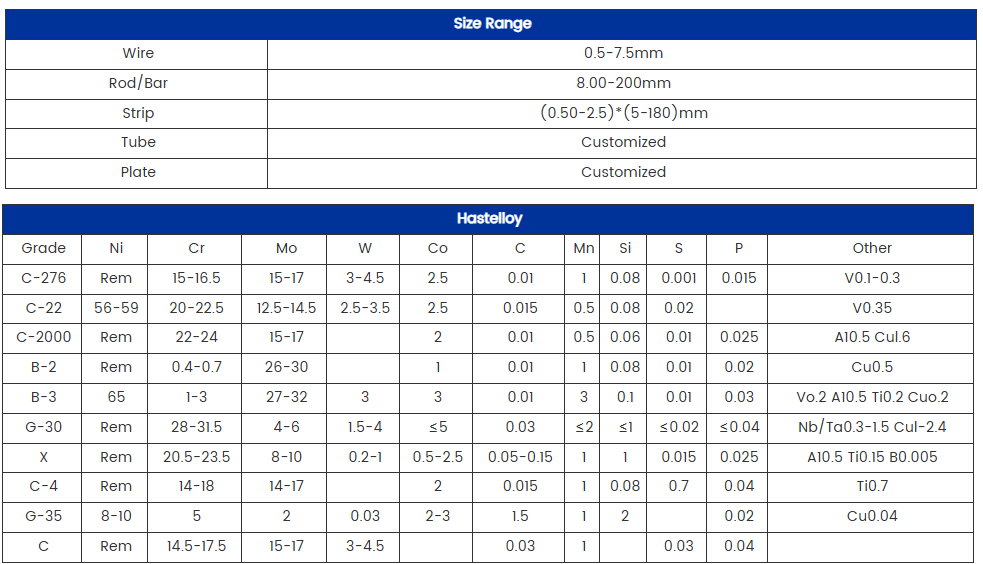

UNS-nummer: N10665

-

ASTM-standards: ASTM B333 (Strimmor & Plåt)

-

EN/DIN-ekvivalent: 2.4617

-

Smältning och legering: Legeringen produceras med vakuuminduktionsmätning (VIM) eller elektrisk bågeugn (EAF) för att bibehålla renhet.

-

Hett- och kallrullning: Uppnår önskad tjocklek och förbättrar mekaniska egenskaper.

-

Annekering och värmebehandling: Förbättrar korrosionsmotstånd och flexibilitet.

-

Ytbehandling: Inkluderar ettring, passivering och polering för optimal prestation.

-

Kvalitetskontroll och tester: Säkerställer efterlevnad av mekaniska, kemiska och dimensionella specifikationer.

-

Varierande strimthickgor och bredder: Tillgängliga i flera dimensioner för specifika tillämpningar.

-

Ytbehandlingsalternativ: Fabriksfärdig, elektropolernad eller belagd för förbättrad hållbarhet.

-

Noggrann slitning och skärningstjänster: Säkerställer exakta dimensioner för användartillämpningar.

-

Efterlevnad av internationella standarder: Mottar ASTM, ASME och andra reglerande certifieringar.

Hastelloy B-2 är en nikkel-molybdenalloy som är känd för sin utmärkta motståndighet mot höggradigt reducerande miljöer, såsom hydroklor syra och andra aggressiva kemikalier. När tillverkad till precisionsplåtar ger detta material utmärkt korrosionsmotstånd, hög mekanisk styrka och anpassningsbarhet, vilket gör det lämpligt för ett brett spektrum av industriella tillämpningar.

Materialens sammansättning och egenskaper

Hastelloy B-2-plåtar består huvudsakligen av nikkel och molybden och erbjuder följande nyckelfördelar:

Användningsområden för Hastelloy B-2 plåtar

Tack vare sina utmärkta kemiska och mekaniska egenskaper används Hastelloy B-2 plåtar i flera industrier, inklusive:

Kvaliteter och normer

Hastelloy B-2 plåtar uppfyller internationella standarder för att säkerställa högkvalitativ prestanda:

Tillverkningsprocess

Produktionen av Hastelloy B-2 plåtar involverar avancerade metallurgiska tekniker för att säkerställa precision och pålitlighet:

Användarbehov och anpassning

Industrier som använder Hastelloy B-2-plattor kräver ofta anpassade specifikationer för att möta operativa behov. Vanliga anpassningsalternativ inkluderar:

Frågor:

Hur lång leveranstid har ni?

Det beror på beställningsmängden, 10-30 dagar för små beställningar. För stora beställningar tar det 60 dagar.

Accepterar ni OEM/ODM-produktion?

Ja! Vi accepterar OEM/ODM-produktion. Du kan skicka oss dina prov eller ritningar.

Hur kontrollerar ni kvaliteten på era produkter? Möt kemiska egenskaper hos produkterna kvalitetsnormerna?

Med en professionell kvalitetsteam, avancerad produktkvalitetsplanering, strikt genomförande och kontinuerlig förbättring, kommer vi att utfärda produktkvalitetsintyg, inklusive kemisk analysrapport.

Kan er företag tillhandahålla detaljerade tekniska data och ritningar?

Ja, du kan. Berätta för oss vilka produkter och tillämpningar du behöver, och vi kommer att skicka dig detaljerade tekniska data och ritningar för din utvärdering och bekräftelse.

Hur hanterar ni försäljningstjänster och efterföljande service?

Vi har ett professionellt företagsteam som arbetar en till en för att skydda dina produktbehov, och om du har några frågor, kan han svara på dem för dig!

Kan jag besöka er fabrik innan jag gör en order?

Ja, du är välkommen att besöka vår fabrik. Vi är glada över möjligheten att komma åt varandra.

Var ligger din produktionsbas?

Vi tillverkar våra produkter i Jiangsu, Kina och skickar dem från Kina till ditt land så snabbt som möjligt, vilket vanligtvis beror på dina produktspecifikationer och kvantitet.

Kan du skicka prover?

- Ja, det kan vi.