Superior Heat Resistance with 1Cr13Al4 and 0Cr25Al5 FeCrAl Alloys for High-Performance Applications

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

-

1Cr13Al4: This alloy contains 13% chromium and 4% aluminum. It strikes a balance between high strength, heat resistance, and oxidation resistance. Designed to perform reliably at temperatures up to 1200°C, 1Cr13Al4 is a preferred choice in industrial applications that require high thermal stability and mechanical strength in the presence of high heat.

-

0Cr25Al5: Featuring 25% chromium and 5% aluminum, this alloy offers superior heat resistance and oxidation protection. It is capable of withstanding temperatures as high as 1300°C. The high chromium content improves its resistance to oxidation and corrosion, making it an excellent choice for applications where reliability under extreme heat is critical.

- FeCrAl alloys, particularly 1Cr13Al4 and 0Cr25Al5, are widely used in industrial heating elements, including those used in furnaces, kilns, and heat treatment processes. Their ability to withstand temperatures above 1200°C without losing structural integrity makes them ideal for these applications.

- These alloys are employed in electric heating elements used in a variety of commercial and industrial applications such as water heaters, ovens, and space heaters. The alloys’ high resistance to oxidation ensures that the heating elements can maintain stable performance over time, even under prolonged exposure to heat.

- In power plants, FeCrAl alloys are used in heating systems such as steam generators, turbines, and exhaust systems. Their resistance to oxidation at high temperatures ensures reliable operation in harsh environments, making them indispensable in maintaining the efficiency of power generation systems.

- FeCrAl alloys are utilized in laboratory heating elements, sterilizers, and other scientific instruments that require consistent, reliable heat. Their excellent heat resistance allows them to perform effectively in applications where precise temperature control is necessary.

- The aerospace and automotive industries rely on FeCrAl alloys for their high-temperature resistance in components such as exhaust systems, catalytic converters, and heating elements within vehicles. These alloys ensure that critical parts continue to function even under high stress and extreme temperatures.

-

1Cr13Al4: With 13% chromium and 4% aluminum, this alloy provides a balanced combination of heat resistance, electrical resistance, and mechanical strength. It is ideal for use in applications that require stable performance at temperatures up to 1200°C. This alloy is particularly useful in industrial and commercial heating elements where durability and efficiency are essential.

-

0Cr25Al5: Offering 25% chromium and 5% aluminum, 0Cr25Al5 provides superior heat resistance and corrosion resistance. This alloy is designed to withstand even higher temperatures, making it suitable for applications where the heating elements must operate efficiently at temperatures above 1200°C and even up to 1300°C.

-

Melting and Alloying: The first step involves melting the raw materials, including iron, chromium, and aluminum, in an induction furnace. The process is carefully controlled to ensure that the alloy composition is precise and uniform, which is critical for the final product’s performance.

-

Casting: The molten metal is cast into billets or ingots. This casting process ensures that the alloy has a consistent structure and minimal impurities, which is crucial for achieving the desired performance in high-temperature applications.

-

Extrusion and Drawing: After the alloy has solidified, it is subjected to extrusion and drawing processes to create fine wires. These processes ensure that the wire has the desired diameter and mechanical properties. The wires are drawn with precision to ensure consistent electrical resistance.

-

Heat Treatment: The wires undergo heat treatment processes, such as annealing, to relieve internal stresses and enhance the alloy’s mechanical strength, ductility, and heat resistance. This heat treatment is critical for ensuring that the wires can withstand high thermal stresses without degrading.

-

Quality Control and Testing: After the wires are manufactured, they undergo rigorous testing to ensure that they meet the necessary standards for heat resistance, electrical resistance, and mechanical properties. These tests are designed to simulate real-world conditions to verify the alloy’s ability to withstand high temperatures over extended periods.

-

Exceptional Heat Resistance: Both 1Cr13Al4 and 0Cr25Al5 alloys are engineered to perform effectively at elevated temperatures. While 0Cr25Al5 offers a higher temperature tolerance, both alloys provide excellent heat resistance, making them suitable for the most demanding industrial applications.

-

Long Lifespan: These alloys’ resistance to oxidation and corrosion ensures that heating elements made from them last significantly longer compared to traditional materials. This longevity reduces maintenance costs and minimizes downtime in industrial operations.

-

Energy Efficiency: FeCrAl alloys have high electrical resistance, allowing heating elements to efficiently generate heat with lower energy consumption. This efficiency is essential for industries focused on reducing energy costs and improving overall operational efficiency.

-

High Mechanical Strength: Both alloys maintain their mechanical integrity under high thermal stresses. This strength ensures that the heating elements will not warp or degrade under intense heat, even during prolonged use.

-

Cost-Effectiveness: Although the initial investment in FeCrAl alloys may be higher than alternative materials, the long lifespan, superior performance, and reduced maintenance needs make them a cost-effective solution in the long term.

In the world of industrial heating, selecting the right material for resistance wires is paramount to ensuring high efficiency, durability, and long-term performance under extreme conditions. FeCrAl (Iron-Chromium-Aluminum) alloys, specifically 1Cr13Al4 and 0Cr25Al5, are among the most sought-after materials for such applications due to their exceptional heat resistance, oxidation resistance, and mechanical strength. These alloys are designed to perform reliably in high-temperature environments, making them indispensable in various high-performance industrial applications. This article explores the characteristics of these alloys, their applications, grades, manufacturing processes, and how they meet the evolving demands of industries requiring superior heat resistance.

Material Introduction

FeCrAl alloys are composed of iron, chromium, and aluminum. These elements combine to provide outstanding resistance to oxidation and high-temperature stability, making them ideal for applications where heating elements are exposed to extreme temperatures and harsh environments.

Applications

1Cr13Al4 and 0Cr25Al5 FeCrAl alloys are used in a variety of high-performance applications where heating elements need to function efficiently and reliably under intense thermal stress. These alloys are highly valued in industries that require long-lasting and stable heating performance. Below are some key applications where these alloys excel:

1. Industrial Heating Elements

2. Electric Heaters

3. Power Generation

4. Laboratory and Scientific Equipment

5. Aerospace and Automotive

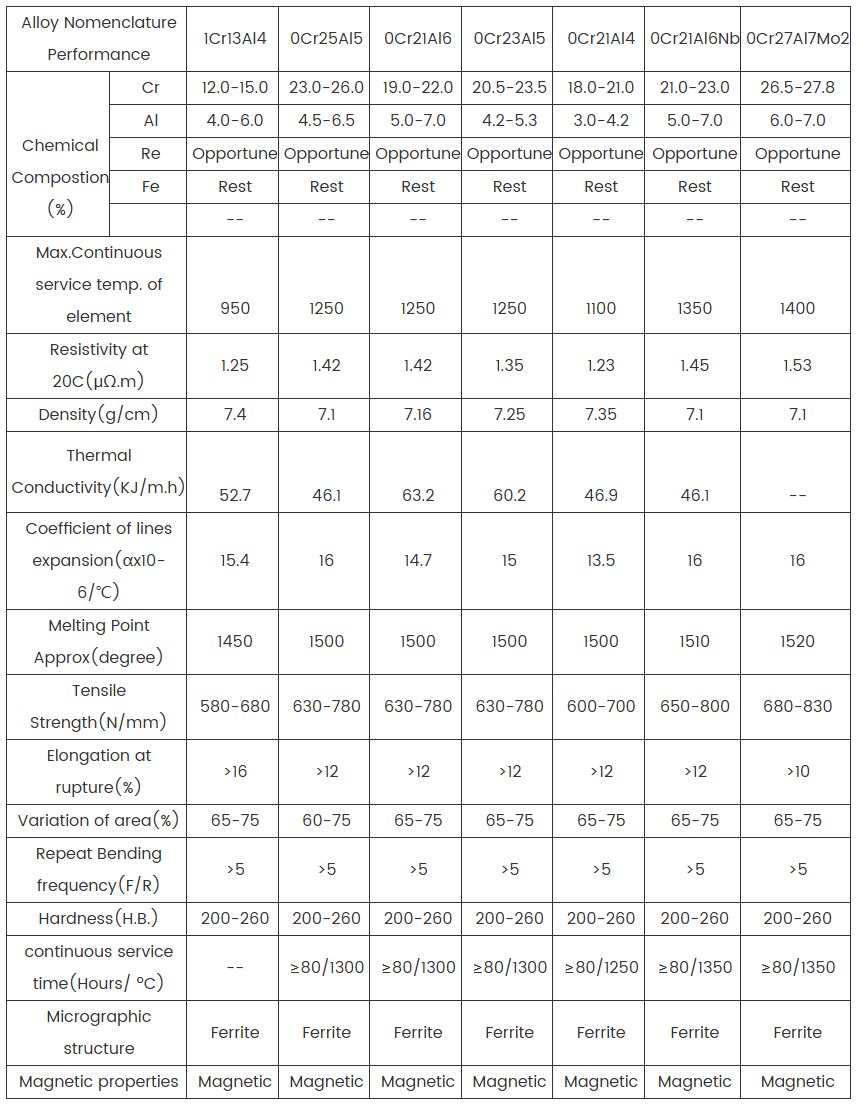

Grades and Specifications

Manufacturing Process

The manufacturing of 1Cr13Al4 and 0Cr25Al5 FeCrAl alloy resistance wires involves several stages to ensure that the alloys maintain their properties of heat resistance, oxidation resistance, and mechanical strength:

Meeting User Demands

Industries that rely on high-performance heating elements demand materials that provide superior heat resistance, long-term durability, and efficient energy use. 1Cr13Al4 and 0Cr25Al5 FeCrAl alloys are designed to meet these needs by offering the following benefits:

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.