Cijevi od Hastelloy C-276 visoke performanse – Savršeni za hemijsku obradu

Ponudjujemo cene direktno sa fabrike i posebne popuste za porudžbine u velikim količinama. Bez obzira da li vam trebaju male ili velike količine, naši proizvodi su brzo dostavljeni kako bi se osigurala pouzdana ponuda za industrijske projekte širom sveta.

- Pregled

- Specifikacija

- Primene

- Često postavljana pitanja

- Preporučeni proizvodi

Uvod u trombine od Hastelloy C-276

Trombine od Hastelloy C-276 široko su priznate po izuzetnoj otpornosti na koroziju i visoke temperature, čime postaju priviljna rešenja u industriji hemijske obrade. Ove trombine, sastavljene od aleja nikel-molibden-hrom, nude izvanrednu performansu u agresivnim okruženjima gde tradicionalni materijali ne uspevaju.

Pregled materijala

Hastelloy C-276 (UNS N10276) je alej nikel visokog performansi poznat po izuzetnoj otpornosti na pitting, krepovinsku koroziju i korozionom rušenju pod uticajem napona. Jedinstvena hemijska sastava ovog aleja pruža nepremašivu trajnost i dugotrajnost.

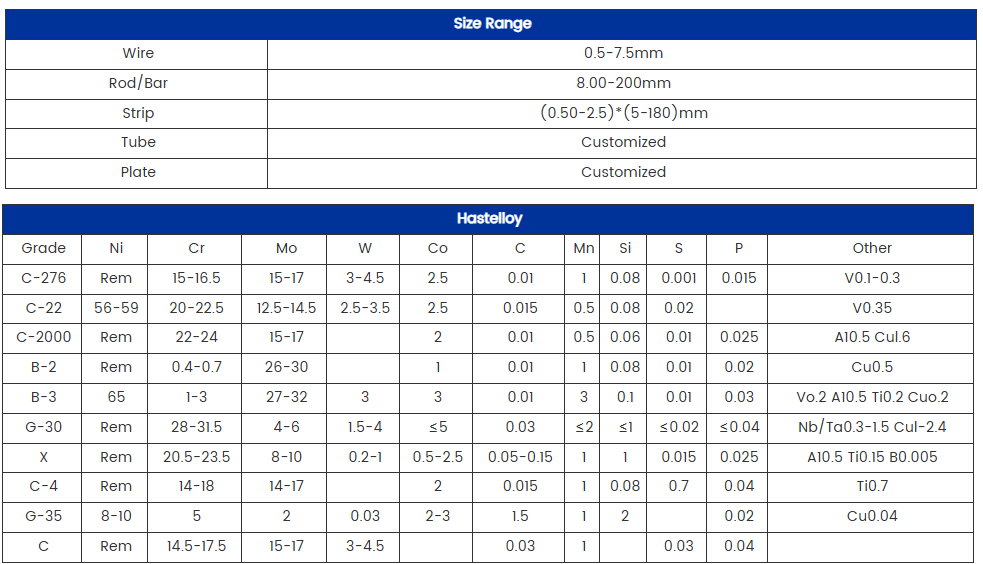

Kemijski sastav:

Nikel (Ni): Balans

Molibden (Mo): 15.0-17.0%

Hrom (Cr): 14.5-16.5%

Željezo (Fe): 4.0-7.0%

Kobalt (Co): ≤ 2.5%

Volfram (W): 3.0-4.5%

Ugljenik (C): ≤ 0.01%

Mangan (Mn): ≤ 1.0%

Kремициум (Si): ≤ 0.08%

Sufur (S): ≤ 0.03%

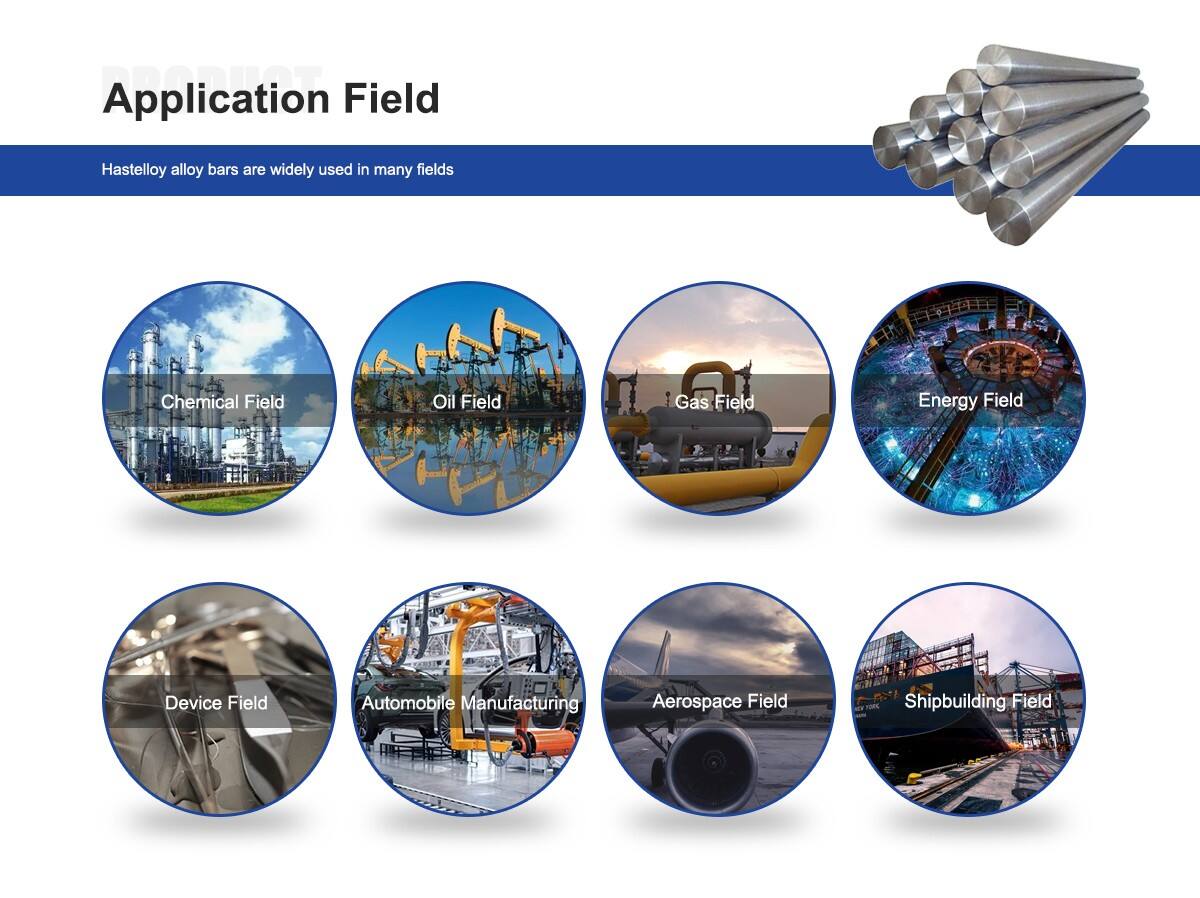

Primena cevova od Hastelloja C-276

Zbog svoje izuzetne hemijske otpornosti i mehaničkih osobina, cijevi od Hastelloy C-276 široko se koriste u različitim industrijama, uključujući:

Hemijska obrada: Idealno za reaktore, cevi i posude koje rade sa jakim kiselinama i oksidirajućim sredinama.

Farmaceutska i prehrana obrada: Osigurava kontaminaciju-slobodnu transportiranje tekućina u ključnim primenama.

Energetski objekti: Koriste se u toplomjenicama, kondenzatorima i sistemima dezelifikacije flue gasova.

Maritima i offshore: Odlična otpornost na koroziju marino vode čini je prikladnom za destilacione raste i offshore konstrukcije.

Aerosvemirska industrija: Primenjuje se u visoko temperaturnim sredinama gde je otpornost na koroziju ključna.

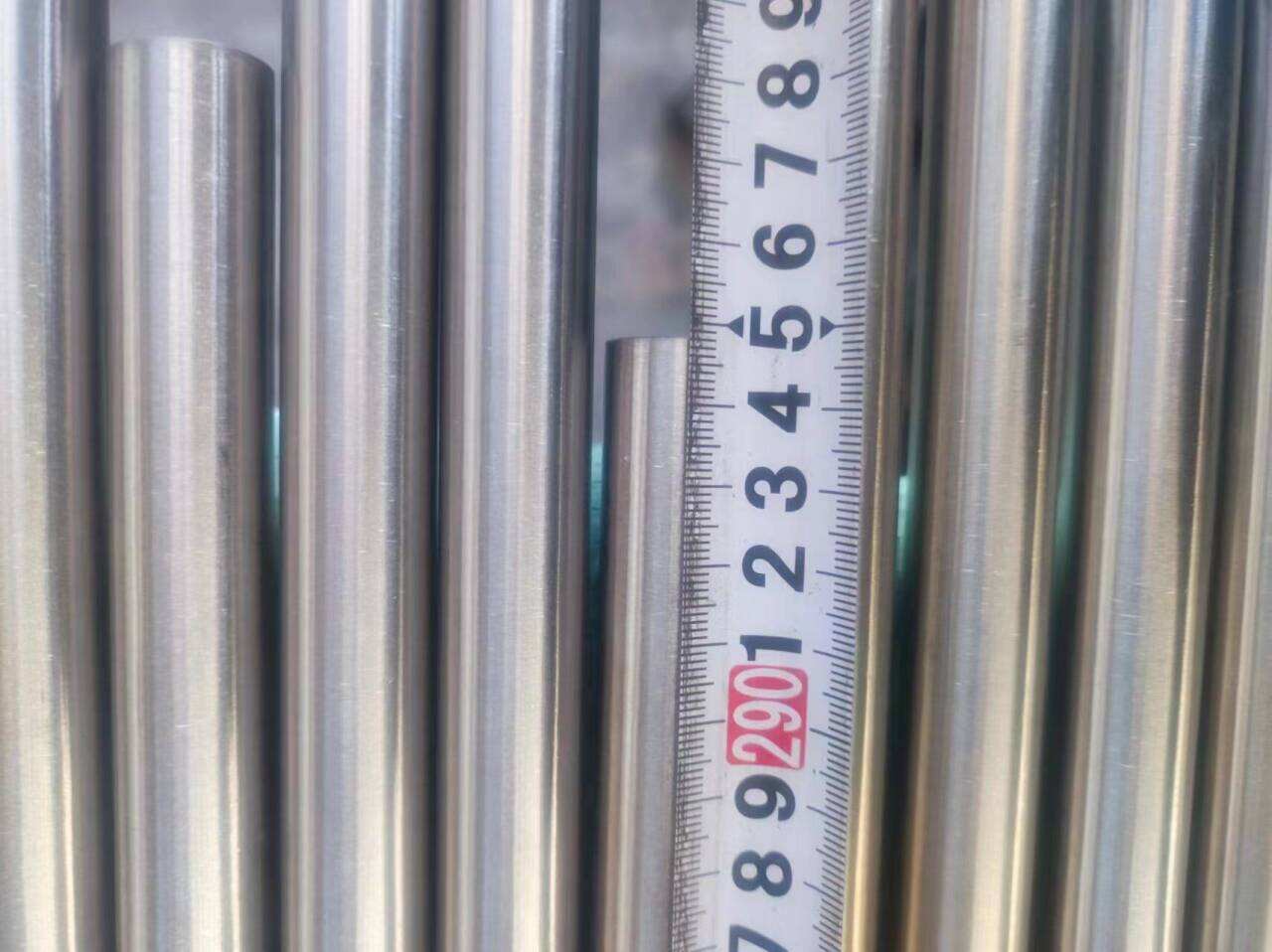

Tipovi cijevi od Hastelloy C-276

Cijevi od Hastelloy C-276 dostupni su u različitim konfiguracijama kako bi zadovoljili industrijske zahteve:

Bezrežne cijevi: Proizvedene bez svarenja, pružaju veću jačinu i otpornost na tlak.

Svarene cijevi: Ekonomičnije i prikladne za manje ekstremne primene.

Cevi za razmenu topline: Dizajnirane za efikasnu prenosu topline u agresivnim okolinjima.

Instrumentacione cevi: Koriste se u aplikacijama sa visokom preciznošću koje zahtevaju nepropustnu performansu.

Производствени процес

Proizvodnja cevi od Hastelloy C-276 sledi strogi proces kontrole kvaliteta kako bi se osigurala trajnost i pouzdanost:

Izbor sirovine: Koristi se premium kvaliteta alija Hastelloy C-276.

Formiranje cevi: Materijal se izbacuje ili valjuje u cele ili zavarivane cevi.

Termalna obrada: Rezolucijsko otpalivanje poboljšava otpornost na koroziju i mehaničku čvrstoću.

Završna obrada površine: Kiselinačenje i pasivacija poboljšavaju čistoću i dugotrajnost.

Kontrola kvaliteta i testiranje: Uključuje hidrostatičko, elektromagnetsko i ultrazvukovsko testiranje kako bi se ispunile standardi ASTM B622 i ASTM B619.

Zahtev korisnika i tržišne trendove

Zahtev za cevima od Hastelloy C-276 raste zbog porasta industrijskih zahteva za pouzdanim i koroziono otpornim materijalima. Tržišne tendencije uključuju:

Opcije prilagođavanja: Dostupne su u različitim veličinama, debljinama zida i specifikacijama.

Porudžbine u velikom obimu i ekonomičnost: Ponuda iz fabrike osigurava konkurentne cene.

Strog poštivanje propisa: Odgovara međunarodnim standardima, osiguravajući sigurnost i performanse.

Globalna distribucija: Poverljive lanac snabdevanja za vreme poštaranja širom sveta.

Закључак

Cijevi od Hastelloya C-276 predstavljaju ključni element u industrijama koje zahtevaju visoku otpornost na koroziju i mehaničku čvrstoću. Njihova sposobnost da pretrpe ekstremne hemijske sredine čini ih nezamenjivim u hemijskoj obradi, maritimnoj, aerokosmičkoj i energetskoj industriji. Sa rastućim industrialnim potrebama, cijevi od Hastelloya C-276 ostaju najbolji izbor za osiguravanje sigurnosti, trajnosti i performansi u kritičnim primenama.

Česta pitanja:

Колико траје испорука?

Zavisi od količine narudžbine, 10-30 dana za male narudžbine. Za velike narudžbine, potrebno je 60 dana.

Da li prihvatate OEM/ODM proizvodnju?

Da! Prihvatamo OEM/ODM proizvodnju. Možete nam poslati vaše uzorke ili crteže.

Kako kontrolirate kvalitet vaših proizvoda? Da li hemijske osobine proizvoda ispunjavaju standard kvaliteta?

Sa profesionalnim timom za kvalitet, naprednom planiranjem kvaliteta proizvoda, strogom implementacijom i neprestanim unapređivanjem, izdat ćemo sertifikat o inspekciji kvaliteta proizvoda, uključujući izveštaj o hemijskoj analizi.

Može li vaša kompanija pružiti detaljne tehničke podatke i crteže?

Da, možete. Recite nam koje proizvode i primene trebate, a mi ćemo vam poslati detaljne tehničke podatke i crteže za vašu procenu i potvrdu.

Kako obrađujete usluge pre i posle prodaje?

Imamo profesionalni poslovni tim koji će raditi jedan na jedan da bi štitovalao vaše potrebe proizvoda, a ako imate bilo kakva pitanja, on će vam ih odgovoriti!

Možem li posetiti vašu fabriku pre poručivanja?

Da, dobrodošli ste da posetite našu fabriku. Srećni smo što imamo priliku da se upoznamo.

Gde je vaša proizvodna baza?

Proizvodimo naše proizvode u Džiangsu, Kina i šaljemo ih iz Kine u vašu zemlju što prije, što uglavnom zavisi od zahteva za proizvodom i količinom.

Možete li poslati uzorke?

Da, možemo.