Hastelloy B-3 Krugli šipovi – Najbolji izbor za ekstremnu otpornost na koroziju

Ponudjujemo cene direktno sa fabrike i posebne popuste za porudžbine u velikim količinama. Bez obzira da li vam trebaju male ili velike količine, naši proizvodi su brzo dostavljeni kako bi se osigurala pouzdana ponuda za industrijske projekte širom sveta.

- Pregled

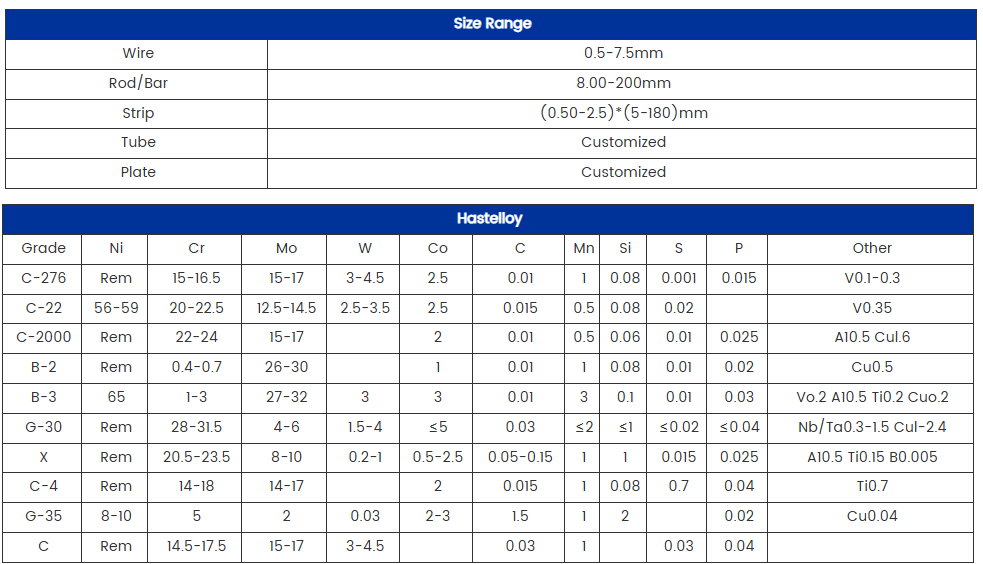

- Specifikacija

- Primene

- Često postavljana pitanja

- Preporučeni proizvodi

-

Izuzetna otpornost na koroziju: Izdržava izuzetno agresivne kemikalije, uključujući šećerne, sumporne i fosforne kiseline.

-

Odlična teporna stabilnost: Održava čvrstoću i otpornost na koroziju čak i pri visokim temperaturama.

-

Visoka mehanička čvrstoća: Osigurava trajnost u ekstremnim uslovima i sprečava koroziono prsćenje uz stres.

-

Odlična obradivost: Lako se frobi, svařuje i procesira bez značajne precipitacije karbida.

-

Industrija hemijske obrade: Koristi se u reaktorima, toplinskim menjacima, cevovodnim sistemima i spremnicama pod pritiskom koji rade sa korozivnim kemikalijama.

-

Aerosvemski i odbrambeni sektor: Korišćen u visoko performantnim strukturnim komponentama izloženim ekstremnim uslovima.

-

Maritimna inženjerija i offshore konstrukcije: Idealna za strukture otporne na moršku vodu i maritiman opremu.

-

Farmaceutska i biotehnološka industrija: Primjenjuje se u opremi za sterilnu obradu koja zahteva visoku otpornost na koroziju.

-

Energija i proizvodnja elektro energije: Koristi se u nuklearnom, geotermalnom i petrohemijaskom sektorima koji zahtevaju materijale s visokom čvrstoćom i otpornosti na koroziju.

-

UNS broj: N10675

-

ASTM standardi: ASTM B335 (Krugle čevre i šipove)

-

EN/DIN ekvivalent: 2.4600

-

Topljenje i legiranje: Proizvedeno pomoću toplinskog indukcijskog topnja (VIM) ili električnog luku (EAF) za maksimalnu čistoću.

-

Toplo i hladno valjanje: Postiže precizne dimenzije i poboljšava mehaničke osobine.

-

Otopljavanje i toplinska obrada: Poboljšava otpornost na koroziju i osigurava strukturnu stabilnost.

-

Završna obrada površine: Uključuje kiselinu, pasivaciju i ciljanje za optimalnu učinkovitost.

-

Kontrola kvaliteta i testiranje: Uključuje procenu mehaničkih osobina, testiranje otpornosti na koroziju i dimenzione inspekcije.

-

Različiti prečnici i dužine šipki: Dostupni u više veličina kako bi se prilagodili različitim industrijskim primenama.

-

Opcije završne obrade površine: Sijajan, crno, ili precizno ciljana završna obrada za poboljšanu trajnost.

-

Usluge preciznog strepanja i reza: Osiguravaju tačne dimenzije i saglasnost sa primenom.

-

Prilagođena proizvodnja za OEM i masovne narudžbine: Prilagođeno proizvodnja za velike industrijske projekte.

Hastelloy B-3 je visoko performantna nikl-molibden alija dizajnirana za izuzetnu otpornost na vrlo reducirajuće sredine, posebno ugljovodničku kiselinu i druge agresivne kemikalije. U obliku kruglih šipki, ova alija nudi odličnu mehaničku čvrstoću, otpornost na koroziju i trajnost, čime postaje odličan izbor za zahtevne industrijske primene.

Sastav materijala i svojstva

Hastelloy B-3 krugle šipke se sastoje glavno od nikla i molibdena, pružajući poboljšanu stabilnost i otpor napadima kemikalija. Ključne karakteristike uključuju:

Primene Hastelloy B-3 kruglih traka

Zahvaljujući svojim izuzetnim osobinama, Hastelloy B-3 krugle trake su široko korišćene u:

Oznake i standardi

Hastelloy B-3 krugle šipke ispunjavaju stroge međunarodne standarde kako bi se osigurala visoka kvaliteta i pouzdanost:

Производствени процес

Proizvodnja Hastelloy B-3 kruglih traka sledi napredne metalurške tehnike kako bi se osigurala preciznost i izuzetna performansa:

Zahtevi korisnika i prilagođavanje

Industrije koje koriste Hastelloy B-3 zaokružene trake često zahtevaju prilagođene specifikacije kako bi ispunile svoje operativne potrebe. Uobičajene prilagođavanja uključuju:

Česta pitanja:

Колико траје испорука?

Zavisi od količine narudžbine, 10-30 dana za male narudžbine. Za velike narudžbine, potrebno je 60 dana.

Da li prihvatate OEM/ODM proizvodnju?

Da! Prihvatamo OEM/ODM proizvodnju. Možete nam poslati vaše uzorke ili crteže.

Kako kontrolirate kvalitet vaših proizvoda? Da li hemijske osobine proizvoda ispunjavaju standard kvaliteta?

Sa profesionalnim timom za kvalitet, naprednom planiranjem kvaliteta proizvoda, strogom implementacijom i neprestanim unapređivanjem, izdat ćemo sertifikat o inspekciji kvaliteta proizvoda, uključujući izveštaj o hemijskoj analizi.

Može li vaša kompanija pružiti detaljne tehničke podatke i crteže?

Da, možete. Recite nam koje proizvode i primene trebate, a mi ćemo vam poslati detaljne tehničke podatke i crteže za vašu procenu i potvrdu.

Kako obrađujete usluge pre i posle prodaje?

Imamo profesionalni poslovni tim koji će raditi jedan na jedan da bi štitovalao vaše potrebe proizvoda, a ako imate bilo kakva pitanja, on će vam ih odgovoriti!

Možem li posetiti vašu fabriku pre poručivanja?

Da, dobrodošli ste da posetite našu fabriku. Srećni smo što imamo priliku da se upoznamo.

Gde je vaša proizvodna baza?

Proizvodimo naše proizvode u Džiangsu, Kina i šaljemo ih iz Kine u vašu zemlju što prije, što uglavnom zavisi od zahteva za proizvodom i količinom.

Možete li poslati uzorke?

Da, možemo.