Kupite ERNiCrMo-4 (C-276) Svarkivu Žicu U Velikom Obimu – Garantovane Niske Cene

- Pregled

- Preporučeni proizvodi

Uvod u ERNiCrMo-4 (C-276) svarku žicu

ERNiCrMo-4 (C-276) svarka šipka je nikl-hrom-molibden alijansa dizajnirana za visoko performanse u primenama za svarku u korozivnim, visokim pritiskom i visokotemperaturnim sredinama. Poznata po izuzetnoj otpornosti na koroziju, prekrasnoj mehaničkoj čvrstoći i odličnoj sposobnosti za svarku, ova svarka šipka se široko koristi u industrijama kao što su nafta i plin, hemijska obrada, proizvodnja energije, aerodrom i pomorska inženjerija.

Ponudjujemo veličinsku dobavu ERNiCrMo-4 svarkivane žice po ceni iz fabrike, osiguravajući kvalitetna i ekonomična rešenja za industrijske projekte u oblasti svarivanja. Sa popustima za veličinsku prodaju, prilagođenim pakovanjem i brzom dostavom, mi smo vaš pouzdan partner za sve potrebe u oblasti svarivanja.

Pregled materijala: Osobine ERNiCrMo-4 (C-276) svarkivacke drvenice

ERNiCrMo-4 (C-276), takođe poznat kao Hastelloy® C-276, nudi izuzetnu performansu u zahtevnim primenama zahvaljujući svojim odličnim osobinama materijala:

✔ Odlična otpornost na koroziju – Izdržava pitting, krepovinsku koroziju i stresnu korozionu trbinu u kiselinim, hloridnim i visokosuphurnim sredinama.

✔ Stabilnost pri visokim temperaturama – Održava strukturnu čvrstoću pri temperaturama do 1093°C (2000°F).

✔ Izuzetna svarenjivost – Osigurava čiste, jakne i bezdefektna spojeve sa minimalnom topnom trbinom.

✔ Otpornost na oštećujuće hemijske tvari – Idealno za hemijske rafinerije, nafteure i offshore platforme.

✔ Visoka čvrstoća i trajnost – Izdržava aplikacije pod visokim naprezanjima i visokim pritiscima u ekstremnim uslovima.

Ove osobine čine da je ERNiCrMo-4 svarkivana žica prihvaćen izbor za svarivanje koroziono otpornih legura u industrialnim sektorima.

Industrijski standardi i specifikacije

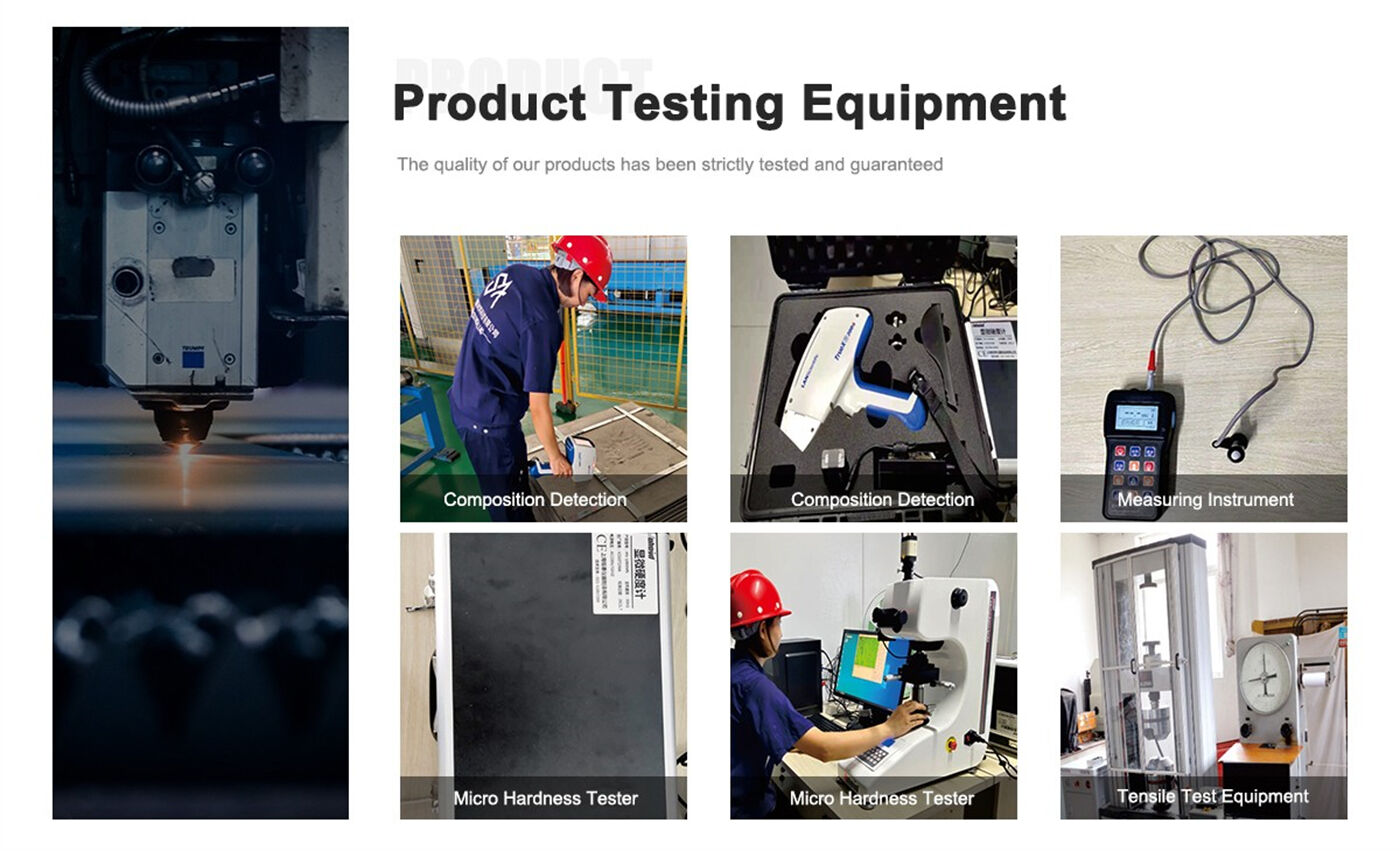

Naša ERNiCrMo-4 (C-276) svarkivana žica proizvedena je u skladu sa međunarodnim standardima kvaliteta, osiguravajući izuzetnu performansu i pouzdanost.

Serija za svarivanje:

ERNiCrMo-3, ERNiCrMo-4, ERNiCrMo-13, ERNiCrFe-3, ERNiCrFe-7, ERNiCr-3, ERNiCr-7, ERNiCu-7, ERNi-1, ER70S-6.

Standard: U skladu sa certifikatom AWS A5.14 ASME SFA A5.14

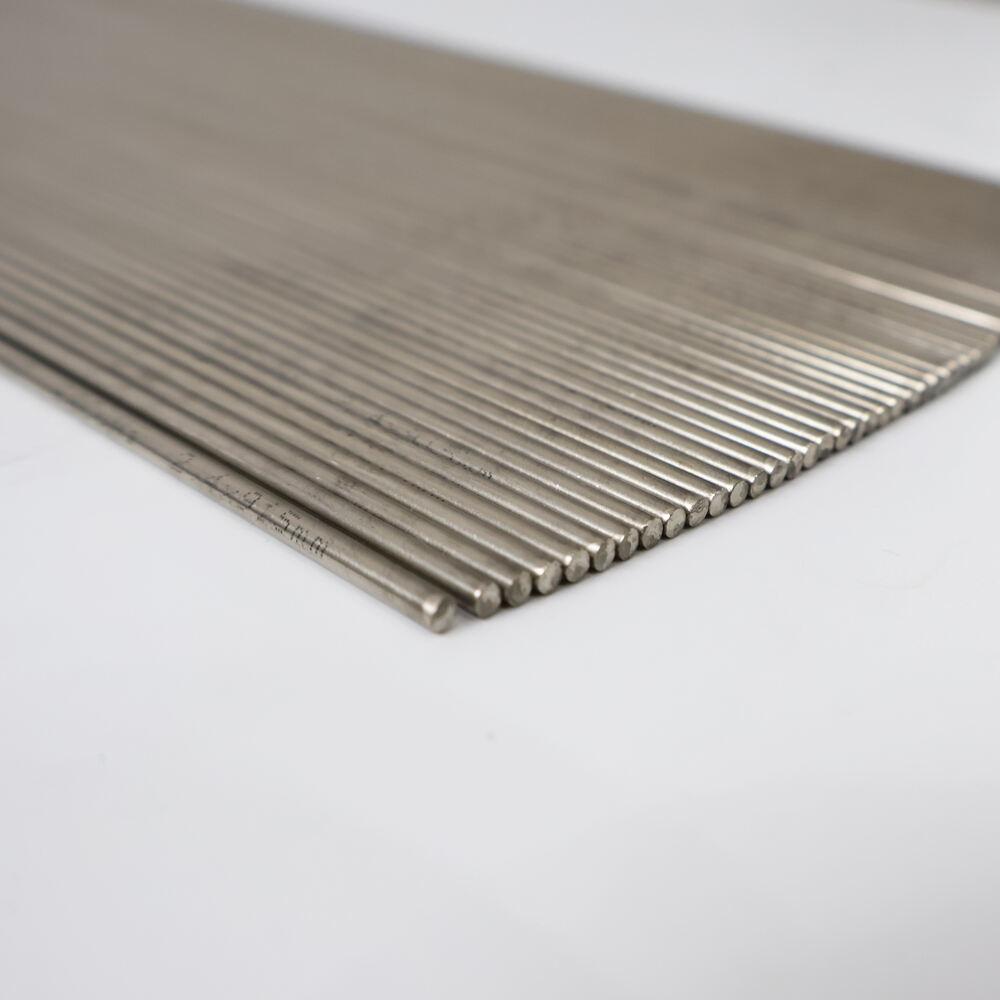

Величина: 0.8MM / 1.0MM / 1.2MM / 1.6MM / 2.4MM / 3.2MM / 3.8MM / 4.0MM / 5.0MM

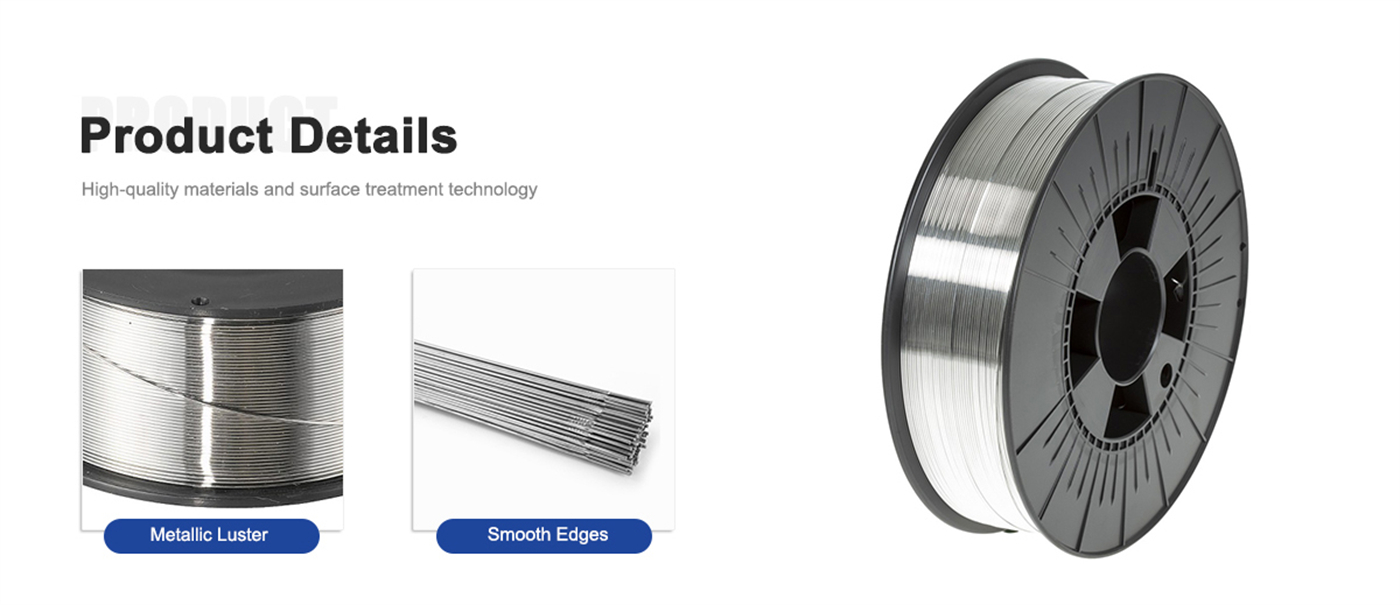

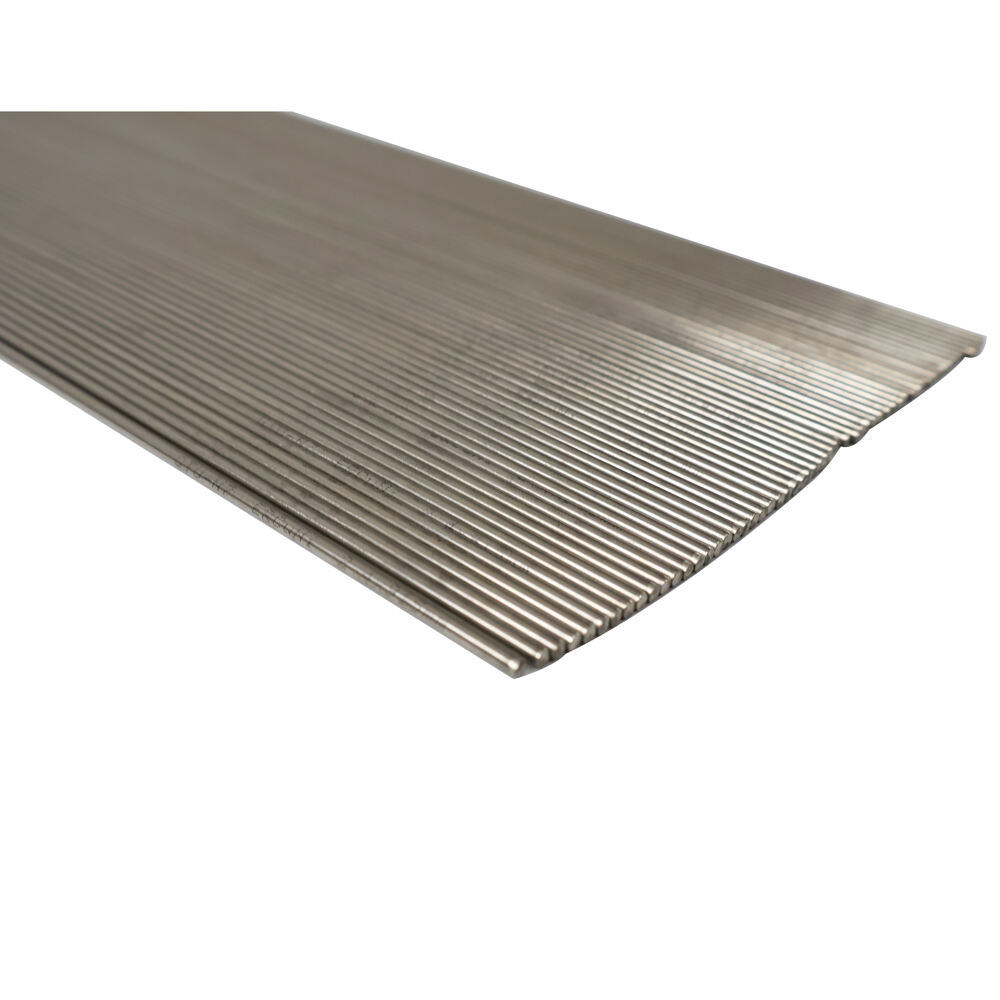

Forma: MIG (15kg/spool), TIG (5kg/box), Strip

Standardna specifikacija

AWS A5.14 ERNiCrMo-4

UNS broj N10276

ASTM Standard ASTM B574, ASTM B575

ISO Standard ISO 18274: NiCr15Mo16Fe6W4

Ovi sertifikati osiguravaju da naša svarkivacka žica ispunjava najstroža zahtevanja industrijalnog sektora za svarku kritičnih komponenti u visoko rizičnim okruženjima.

Primene ERNiCrMo-4 (C-276) svarkive niti

1. Naftno i gasno delatnost

Svarka cijevi – otporna na sulfidno-stresno štapanje i vodonikovu krhotinu u okruženjima sa kiselim plinom.

Nadморске платформе и подводне опреме – Odoljavaju korозију морске воде и екстремним притисним условима.

Опрема за рафинирање – Користи се у топлотним мењачима, реакторима и јединицама за дистилацију нефта.

2. Хемијске обрадне плантације

Резервоари и цевоводи за чување киселина – Приступни за корозију у окруженију сулфатне, хидрохлоридне и нитричне киселине.

Топлотни мењачи и притисним јединице – Осигурава издржљивост у операцијама при високом притиску и температури.

3. Производња електричне енергије и нуклеарна индустрија

Компоненти нуклеарног реактора – Одржава одупорност против зрачења и корозије у нуклеарним електранама.

Гасне и парне турбине – Пружа одупорност оксидацији у услова високе температуре.

4. Aerodromna i pomorska inženjerija

Компоненти авионских motoра – Идеални за делове реактивних motoра и системе високотемпературних издувача.

Brodogradnja i sistem za obalu – Spašava od korozije u maritimskim i dubokomorskim primenama.

5. Prehrambena i farmaceutska industrija

Sanitarni cijevi i oprema za obradu – Osigurava higijensko i bez kontaminacije spajanje.

Oprema za sterilizaciju – Pruža visoku otpornost na koroziju u medicinskim i prehrambenim primenama.

Зашто изабрати нашу сварну жичу ERNiCrMo-4 (C-276)?

Cenovnik direktno sa fabrike za veličinu porudžbine – Garantovano niske cene za velike narudžbine i maloprodaju.

Certifikovana kvalitetna legura – Odgovara standardima AWS, ASTM i ISO za industriju.

Prilagođene veličine i ambalaže – Dostupno u bobinama, spirale i opcijama presecivanja po željenoj dužini.

Brza i pouzdana globalna dostava – Brzo šalje kupcima širom sveta.

Konstantno snabdevanje i raspoloživost zaliha – Osigurava vreme po isporuci za industrijske projekte.

Naručite ERNiCrMo-4 (C-276) svarkivušicu u velikim količinama danas!

Potražujete visokokvalitetnu svarkivu žicu po maloprodajnim cenama? Kontaktirajte nas za porudžbine u velikom obimu, prilagođena rešenja i brzu širom sveta dostavu.

| Stavka | ERNiCrMo-3 | ERNiCrMo-4 | ERNiCrMo-13 | ERNiCrFe-7 | ERNiCr-3 | ERNiCu-7 | ERCuNi | ERNi-1 |

| C | 0.1 | 0.02 | 0.01 | 0.04 | 0.1 | 0.15 | 0.03 | 0.15 |

| Mn | 0.05 | 1 | 0.5 | 1 | 2.5-3.5 | 4 | 0.5-1.0 | 1 |

| Фе | 5 | 4-7 | 1.5 | 7-11 | 3 | 2.5 | 0.65 | 1 |

| P | 0.02 | 0.04 | 0.015 | 0.02 | 0.03 | 0.02 | 0.01 | 0.03 |

| S | 0.015 | 0.03 | 0.005 | 0.015 | 0.015 | 0.015 | 0.01 | 0.015 |

| Да | 0.05 | 0.08 | 0.1 | 0.5 | 0.5 | 1.25 | 0.15 | 0.75 |

| Cu | 0.5 | 0.5 | N/A | 0.3 | 0.5 | pauza | pauza | 0.25 |

| Ни | ≥58 | pauza | pauza | pauza | ≥67 | 62-69 | 30-32 | ≥93 |

| Co | N/A | 2.5 | 0.3 | N/A | N/A | N/A | N/A | N/A |

| AL | 0.4 | N/A | 0.1-0.4 | 1.1 | N/A | 1.25 | 0.15 | 1.5 |

| Ti | 0.4 | N/A | N/A | 1 | 0.75 | 1.5-3 | 0.5 | 2-3.5 |

| Cr | 20-23 | 14.5-16.5 | 22-24 | 28.5-31 | 18.0-22.0 | N/A | N/A | N/A |

| Nb+Ta | 3.5-4.15 | N/A | 1.8-2.5 | 0.01 | 2.0-3.0 | N/A | N/A | N/A |

| Mo | 8.0-10 | 15-17 | 15-16 | 0.5 | N/A | N/A | N/A | N/A |

| V | N/A | 0.35 | N/A | N/A | N/A | N/A | N/A | N/A |

| W | N/A | 3.0-4.5 | N/A | N/A | N/A | N/A | N/A | N/A |

| Pauza | ≤ 0,50 | ≤ 0,50 | ≤ 0,50 | ≤ 0,50 | ≤ 0,50 | ≤ 0,50 | ≤ 0,50 | ≤ 0,50 |

| Žica za svarivanje nikel i nikelovih legura | |

| Model proizvoda (AWS) | Primena |

| ERNiCr-3 | Za svarivanje legura 600, 601 i 800 samih po sebi, i za svarivanje različitih oceli između nerusting ocele i ugljikovne ocele ERNiCrFe-7; Za svarivanje Inconel legura unutar ASTM B163, 166, 167 i 168 |

| ERNiCrFe-6 | Za svarivanje ocele i Inconela, svarivanje ocele i nerusting ocele te nikelovih baznih legura |

| ERNiCrCoMo-1 | Različito svarivanje za svarivanje nikel-hrom-kobalt-molibden legura i različitih superlegura |

| ERNiCrMo-3 | Koristi se za svarivanje nikelovih legura, ugljikovne ocele, nerusting ocele i niskolegirane ocele, glavno za svarivanje legura 625, 601, 802 i za svarivanje 9% nikelove legure |

| ERNi-CI | Industrijski čisti nikl za svarivanje mehke i sive litine |

| ERCuNi | Za svarivanje 70/30, 80/20, 90/10 bakernikovih legura |

| ERNiCu-7 | Za svarivanje legura nikla i bakra B127, 163, 164 i 165 itd. |

| ERNi-1 | Za svarivanje čistih nikliranih odliva i štampanja, kao što su legure u sklopu ASTM B160, 161, 162, 163 |

| ERNiFeMn-CI | Za svarivanje kugasto-granulirane litine, ductile litine, mehke litine i sive litine između sebe ili sa neržavljivim celzom, ugljikovom celzom, niskolegiranim celzom i različitim nikliranim legurama |

| ERNiCrMo-4 | Za svarivanje samih legura nikla, hrom-a, molibdena, ili svarivanje legura nikla, hroma, molibdena i celeze i većine drugih nikliranih legura |

| ERNiCrMo-11 | Koristi se za svarivanje legura nikla, hroma, molibdena samih sebe, ili svarivanje legura nikla, hroma, molibdena i celeze i većine drugih nikliranih legura, a takođe može biti korisno za površinsko svarivanje legura nikla, hroma, molibdena i celjskog spoja |

| ERNiCrMo-13 | Za svarivanje niskougljikovih legura nikla, hroma, molibdena |