Plăci Hastelloy B-2 – Material de înaltă calitate pentru medii corozive

Ofertăm preturi direct de la fabrică și reduceri speciale pentru comenzi mari. Indiferent dacă aveți nevoie de cantități mici sau mari, produsele noastre sunt expediate repede pentru a asigura o furnizare de încredere pentru proiecte industriale din întreaga lume.

- Prezentare generală

- Specificitați

- Aplicații

- Întrebări frecvente

- Produse recomandate

-

Rezistență Excepțională la Coroziune: Foarte rezistentă la acid clorhidric și alte agenți redusori puternici.

-

Forță Mecanică Superioară: Păstrează integritatea sa în mediul cu stresuri mari și temperaturi ridicate.

-

Bună Capacitate de Saldare: Poate fi saldat și fabricat ușor fără precipitații semnificative de carburi.

-

Stabilitate Termică Înaltă: Adecvat pentru aplicații care necesită performanță constantă la temperaturi ridicate.

-

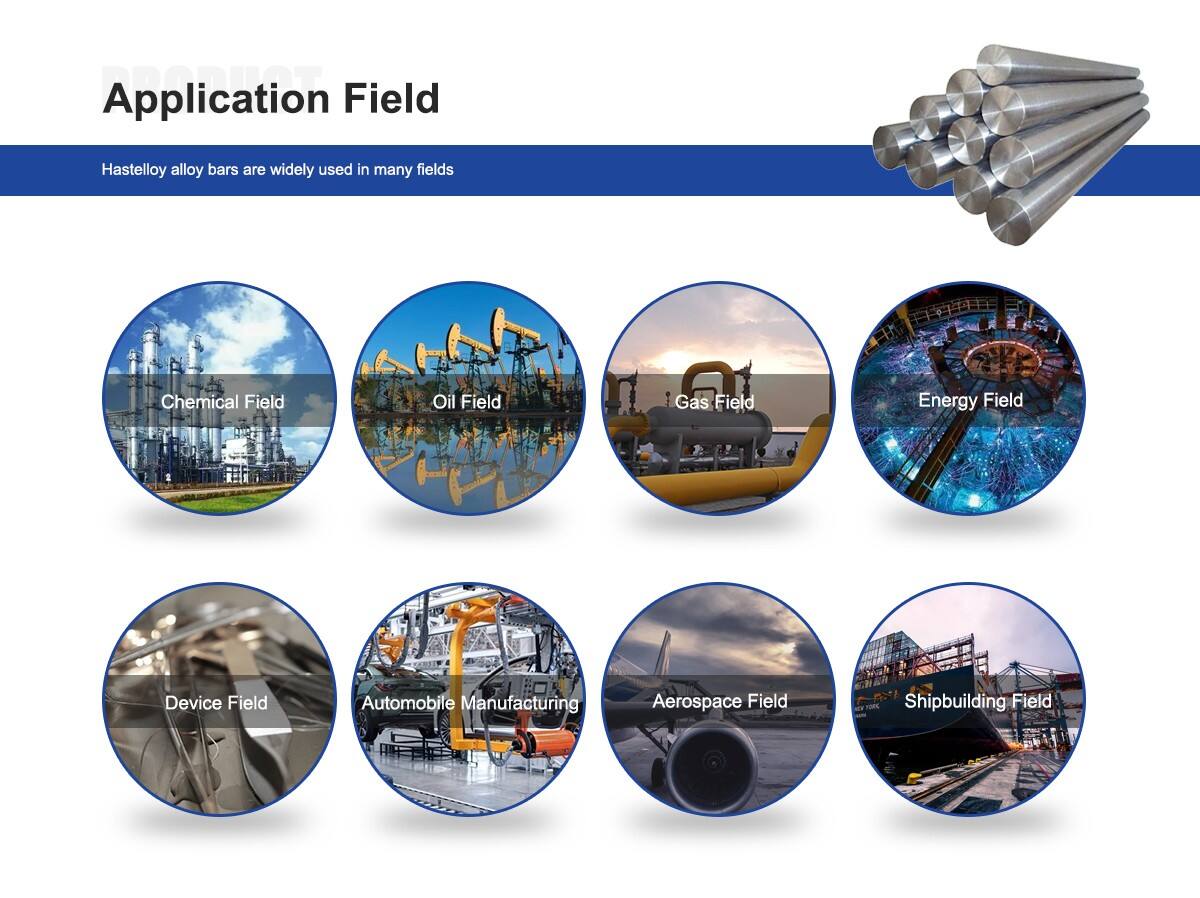

Industria de Procesare Chimică: Utilizată în schimbatoare de căldură, reactoare și vase sub presiune expuse la medii chimice agresive.

-

Industria Farmaceutică și Biotehnologică: Esențială pentru echipamente care manipulează substanțe extrem de reactice în medii sterile.

-

Sectorul Energiei și Generării de Electricitate: Aplicată în sisteme care necesită materiale capabile să reziste temperaturilor ridicate și coroziunii.

-

Industria Cartonului și Hârtiei: Utilizată în echipamente de procesare expuse substanțelor acide și caustice.

-

Inginerie Aerospațială și Marină: Ideal pentru componente expuse condițiilor chimice și marine severe.

-

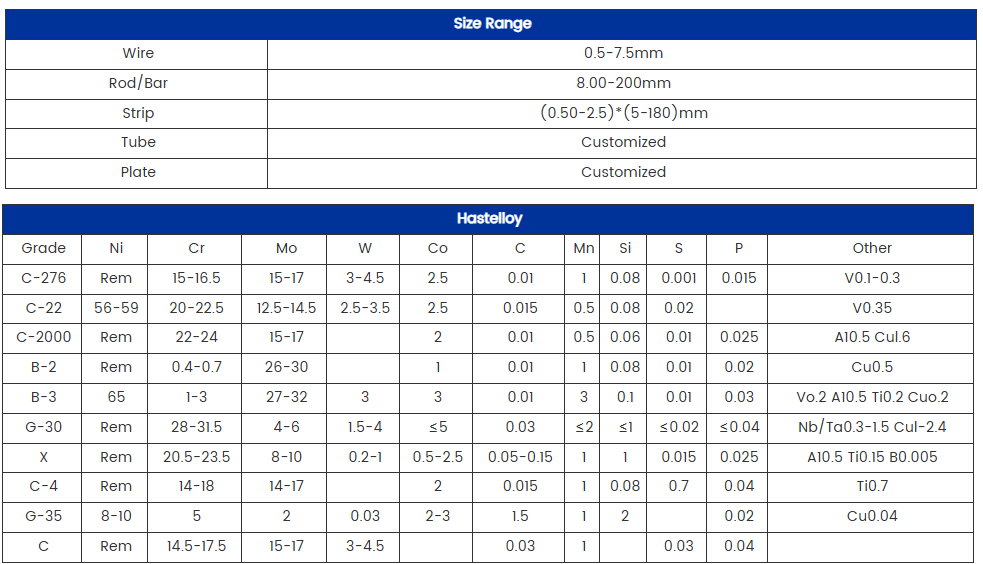

Număr UNS: N10665

-

Standarde ASTM: ASTM B333 (Placi, Foi și Bande)

-

Echivalent EN/DIN: 2.4617

-

Topire și Aliaj: Aliajul suferă o topire prin inducție sub vid (VIM) sau procesare în cuptor cu arc electric (EAF).

-

Laminare și Formare: Tehnici de laminare caldă și rece rafinează materialul în dimensiuni precise ale plăcii.

-

Tratare Termală (Anelarea): Îmbunătățește plasticitatea și rezistența la coroziune.

-

Finalizare Suprafață: Picajul și pasivarea asigură o suprafață curată, rezistentă la coroziune.

-

Control Calitate: Testări riguroase, inclusiv analiza compoziției chimice și evaluarea proprietăților mecanice, garantează conformitatea cu cerințele industriale.

-

Grosime și Dimensiuni Diverse: Plăcile sunt disponibile în diferite mărimi pentru diverse aplicații industriale.

-

Opțiuni de Finisare a Suprafeței: Finish de fabrică, poliată sau îmbrăcată pentru o durabilitate sporită.

-

Sudabilitate și Machinabilitate: Asigurând compatibilitate cu diferite tehnici de fabricație.

-

Conformitate cu standardele reglementare: Îndeplinirea certificărilor ASTM, ASME și alte certificări globale.

Hastelloy B-2 este o aliajă de niob-molibden cunoscută pentru rezistența sa excepțională la medii reductoare precum acizi chlorhidric. Transformată în plăci, această material oferă o performanță remarcabilă în condiții extrem de corrosive, făcând-o o alegere ideală pentru industrii care necesită o durabilitate și o rezistență chimică superioară.

Compoziția materialului și proprietățile

Hastelloy B-2 este compus în principal din niob și molibden, care oferă următoarele avantaje cheie:

Aplicații ale plăcilor Hastelloy B-2

Datorită rezistenței sale ridicate la coroziune, plăcile Hastelloy B-2 sunt utilizate pe scară largă în diverse industrii, inclusiv:

Grade și Standarde

Plăcile Hastelloy B-2 se conformă diferitelor standarde internaționale pentru a asigura calitatea și performanța:

Procesul de fabricare

Producerea plăcilor din Hastelloy B-2 urmează un proces strict pentru a menține standarde ridicate și precizie:

Cerințe Utilizator și Personalizare

Industriile care folosesc plăci Hastelloy B-2 necesită adesea personalizări specifice pentru a satisface nevoile lor operaționale. Specificațiile comune includ:

Concluzie

Plăcile Hastelloy B-2 oferă o rezistență fără precedent în medii extrem de corozive, ceea ce le face esențiale pentru industria care necesită materiale durabile și de performanță ridicată. Proprietățile mecanice superioare, stabilitatea termică și opțiunile de personalizare le fac un alegere excelentă pentru aplicații industriale exigeante.

Întrebări frecvente:

Cât durează livrarea?

Depinde de cantitatea comenzi, 10-30 zile pentru comenzi mici. Pentru comenzi mari, durează 60 de zile.

Acceptați producția OEM/ODM?

Da! Acceptăm producția OEM/ODM. Puteți să ne trimiteți probele sau desenele voastre.

Cum controlați calitatea produselor? Proprietățile chimice ale produselor respectă standardele de calitate?

Cu o echipă profesională de calitate, planificare avansată a calității produselor, implementare strictă și îmbunătățiri continue, vom emite certificat de inspectare a calității produselor, inclusiv raport de analiză chimică.

Poate compania dvs. să ofere date tehnice detaliate și desene?

Da, puteți. Vă rugăm să ne spuneți produsele și aplicațiile pe care le aveți nevoie, iar noi vă vom trimite date tehnice detaliate și desene pentru evaluare și confirmare.

Cum gestionați serviciile pre-vânzare și post-vânzare?

Avem un echipă profesională de afaceri care va lucra cu tine în mod individual pentru a proteja nevoile tale de produse, iar dacă ai întrebări, el le poate răspunde pentru tine!

Pot să vizitez fabrica ta înainte de a plasa o comandă?

Da, sunteți binevenit să vizitați fabrica noastră. Suntem bucuroși să avem ocazia să ne cunoaștem.

Unde se află baza ta de producție?

Producem produsele noastre în Jiangsu, China și le expediem din China către țara ta cât mai curând posibil, ceea ce de obicei depinde de cerințele și cantitatea produselor tale.

Poţi trimite mostre?

Da, putem.