Premium Inconel 718 Spring Wire for Corrosion and Fatigue Resistance

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

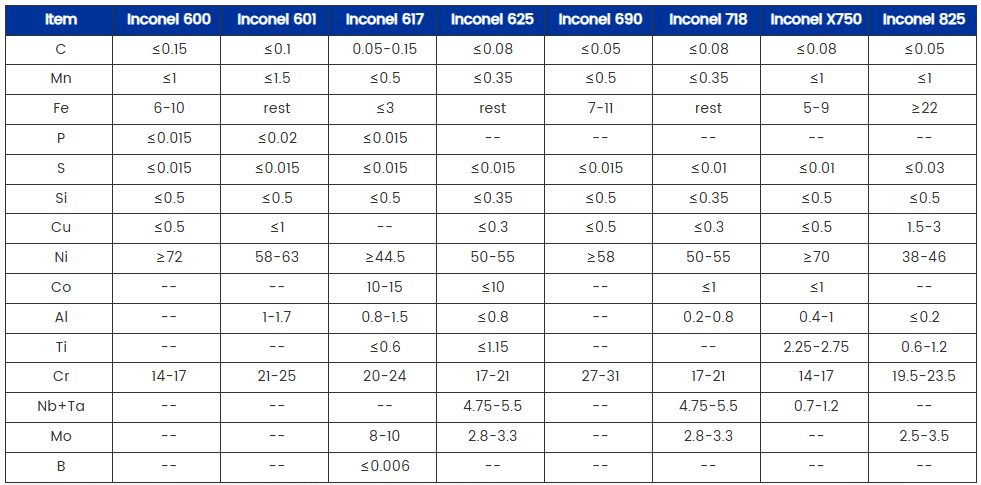

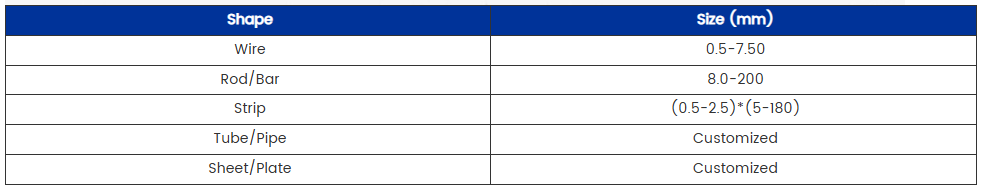

- Specification

- Applications

- FAQs

- Recommended Products

In the world of high-performance engineering materials, Inconel 718 spring wire stands out as an exceptional solution for applications demanding unmatched corrosion resistance and fatigue durability. This nickel-chromium superalloy has become the material of choice for critical applications where reliability under extreme conditions is non-negotiable.

With its unique combination of chemical stability, mechanical strength, and long-term fatigue performance, premium Inconel 718 spring wire is revolutionizing industries from aerospace to deep-sea exploration. This article examines its material properties, key applications, and the industry trends driving its increasing adoption.

Unparalleled Material Properties

1. Superior Corrosion Resistance

Excellent resistance to pitting, crevice corrosion, and stress corrosion cracking

Performs flawlessly in acidic, alkaline, and chloride-rich environments

Maintains integrity in oxidizing and reducing atmospheres

Ideal for marine applications with exceptional seawater resistance

2. Exceptional Fatigue Performance

High-cycle fatigue resistance surpassing conventional spring materials

Maintains mechanical properties through millions of load cycles

Proven durability in dynamic, vibration-intensive applications

Consistent performance from cryogenic to high-temperature conditions

3. Mechanical Excellence

Tensile strength up to 180 ksi (1240 MPa)

Yield strength of 150 ksi (1035 MPa)

Maintains properties at temperatures up to 1300°F (704°C)

Good creep resistance under prolonged stress

4. Manufacturing Advantages

Precision-drawn wire available in diameters from 0.1mm to 10mm

Custom heat treatments for optimized performance

Multiple surface finish options for specific applications

Compliant with AMS 5662, AMS 5663, and ASTM B637 standards

Critical Applications Across Industries

Aerospace & Defense

Jet engine valve springs requiring millions of reliable cycles

Aircraft landing gear components subjected to repeated stress

Missile guidance systems demanding corrosion-proof reliability

Spacecraft mechanisms operating in extreme environments

Oil & Gas Sector

Subsea Christmas tree components in deepwater operations

Downhole tool springs for high-pressure extraction

Sour gas service valves resisting H₂S corrosion

Offshore platform safety systems

Energy Generation

Nuclear reactor control rod drive mechanisms

Geothermal plant components handling corrosive fluids

Gas turbine engine springs in power plants

Hydrogen energy system parts

Industrial & Medical

Chemical processing equipment handling aggressive media

Marine propulsion system components

Medical implant mechanisms requiring biocompatibility

Food processing equipment in corrosive cleaning environments

Industry Trends & Future Outlook

1. Expanding Aerospace Demands

Next-generation aircraft requiring more durable components

Increased engine performance pushing material limits

Commercial space race creating new application needs

2. Energy Sector Evolution

Deepwater exploration driving corrosion-resistant solutions

Nuclear energy revival increasing demand for reliable materials

Hydrogen economy development requiring specialized alloys

3. Manufacturing Innovations

Additive manufacturing enabling complex spring geometries

Precision wire forming for customized solutions

Advanced surface treatments extending service life

AI-assisted material development optimizing alloy compositions

4. Sustainability Focus

Recycling initiatives for nickel superalloys

Lifecycle extension technologies

Reduced material waste through advanced manufacturing

Environmental compliance in harsh applications

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.