Premium 4J29 Alloy Rods for High-Precision Sensors in Aerospace and Automotive

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

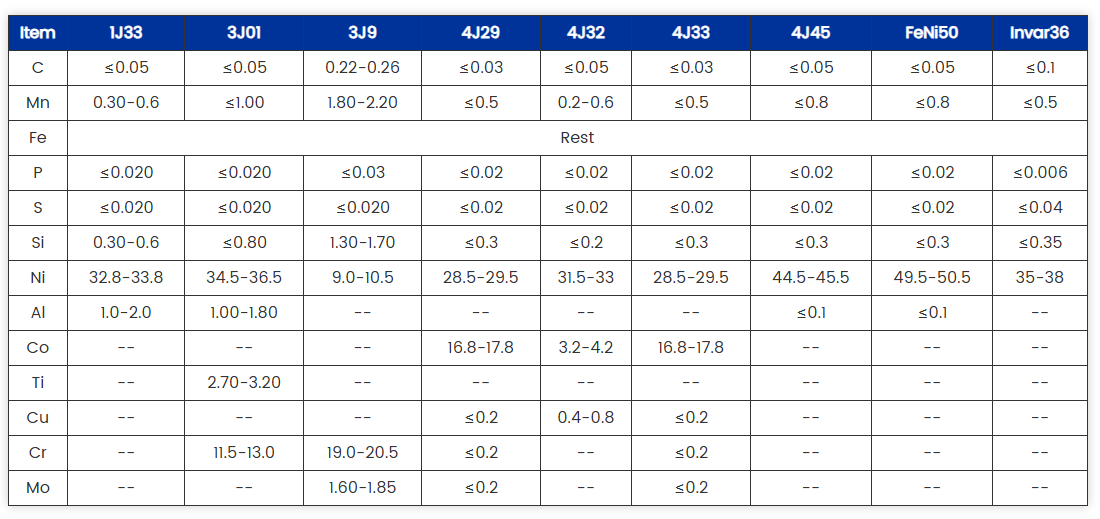

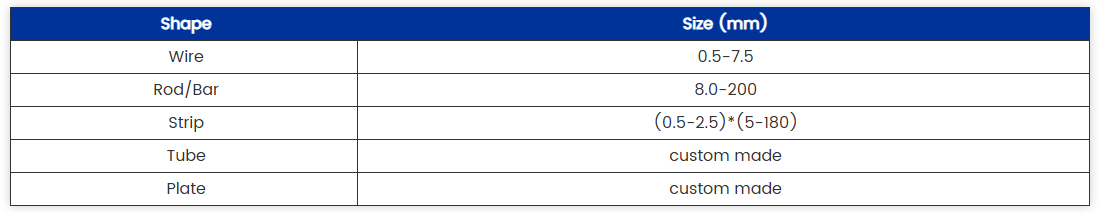

- Specification

- About Us

- FAQs

- Recommended Products

-

Aerospace Sensors

The aerospace industry demands precision and reliability for all its components, especially for sensors. 4J29 alloy rods play a key role in manufacturing sensors for aircraft, satellites, and other aerospace systems. These sensors are exposed to extreme temperature fluctuations as well as high levels of mechanical stress. The low CTE of 4J29 alloy ensures that sensors remain accurate in such conditions, offering unparalleled dimensional stability in both hot and cold environments. Additionally, 4J29’s corrosion resistance ensures that the sensors remain functional in environments with exposure to moisture, radiation, and chemicals. -

Automotive Sensors

Automotive sensors made from 4J29 alloy rods are used for a range of applications including engine management, exhaust systems, and safety features. The automotive industry requires components that can withstand the heat generated by internal combustion engines, exhaust systems, and other high-temperature zones within the vehicle. The thermal stability of 4J29 alloy ensures that automotive sensors provide consistent, accurate readings despite temperature fluctuations, thus ensuring the efficient functioning of systems like fuel injection, exhaust management, and vehicle diagnostics. -

High-Precision Pressure and Temperature Sensors

In both aerospace and automotive applications, pressure sensors and temperature sensors are critical components. These sensors are responsible for monitoring critical parameters, ensuring that vehicles or aircraft operate within safe and efficient ranges. The dimensional stability of 4J29 alloy ensures that these sensors remain accurate under varying temperature conditions, providing consistent performance even in extreme environments. Whether in a jet engine or an automotive exhaust system, 4J29 alloy ensures the longevity and reliability of the sensor systems. -

Precision Gauges and Measuring Instruments

4J29 alloy rods are also used in the manufacturing of precision gauges and measuring instruments. These devices require high accuracy in both readings and structural integrity over time. 4J29 alloy, with its consistent thermal expansion properties, offers manufacturers a reliable material for producing instruments that require accurate measurements in a range of environments. Whether used in aerospace, automotive, or industrial contexts, these gauges continue to provide accurate readings without failure due to temperature fluctuations. -

Sensor Components and Housing

4J29 alloy rods are not only used for the internal elements of sensors but also for their structural components. These may include sensor housings, mounting structures, and protective casings that require stability and resilience. The material’s ability to resist dimensional changes due to heat ensures that the sensor integrity is preserved over time. This is crucial when sensors are subject to vibrations, shocks, and extreme temperature conditions, which are common in both automotive and aerospace environments. -

High Precision and Dimensional Accuracy

One of the most critical requirements for users in aerospace and automotive industries is dimensional accuracy. Sensors and components must provide accurate measurements and operate within very tight tolerances. 4J29 alloy’s low coefficient of thermal expansion makes it the ideal material for these high-precision applications, ensuring that parts do not expand or contract in ways that could compromise performance. -

Thermal Stability

Aerospace and automotive components experience extreme temperature variations during operation. Whether it’s the high heat of an engine or the cold temperatures encountered at high altitudes, components made from 4J29 alloy maintain their size and shape, ensuring that sensors and other critical systems continue to function accurately and reliably. -

Corrosion Resistance

In both aerospace and automotive applications, sensors and components are often exposed to harsh environments, including moisture, chemicals, and pollutants. 4J29 alloy is highly corrosion-resistant, which helps prolong the lifespan of sensors and ensures they continue to perform accurately without being affected by environmental exposure. This resistance to corrosion is especially important in aerospace, where components may be exposed to radiation, chemicals, and high-altitude conditions. -

Mechanical Strength and Durability

Aerospace and automotive components must withstand mechanical stresses such as vibration, pressure, and impact. 4J29 alloy’s high mechanical strength ensures that sensors and related components continue to perform under these stresses. Its durability helps extend the lifespan of sensors and reduces the need for frequent replacements, thus improving the cost-effectiveness of the systems. -

Customization for Specific Applications

Users often require specific forms and dimensions of 4J29 alloy rods to meet the unique needs of their applications. 4J29 alloy rods can be customized in various shapes, sizes, and lengths to accommodate specific sensor designs. Whether a customer needs thin rods for fine sensors or larger bars for structural applications, 4J29 can be tailored to meet these needs. -

High-Performance Reliability

Both aerospace and automotive industries require high-performance reliability from their components. 4J29 alloy meets these demands by offering stable performance over a wide range of temperatures and environmental conditions. Manufacturers and engineers in these industries rely on the consistent high-performance characteristics of 4J29 alloy to ensure that critical systems operate reliably and accurately.

4J29 alloy is a high-performance, nickel-iron alloy specifically designed for applications requiring precise control over thermal expansion. Known for its low coefficient of thermal expansion (CTE) and excellent dimensional stability, 4J29 is used in industries where accuracy and reliability are crucial. Its ability to maintain its shape and size under varying temperature conditions makes it particularly valuable in high-precision applications, such as sensors in both the aerospace and automotive industries.

4J29 alloy rods are used extensively to manufacture high-precision sensors and components that need to maintain accuracy even under extreme environmental conditions. The alloy’s composition and properties ensure that it is highly suited to tasks requiring thermal stability, mechanical strength, and corrosion resistance.

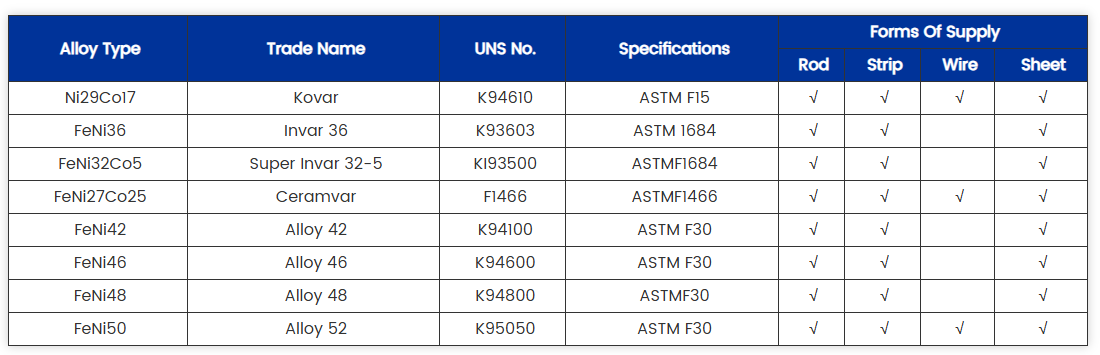

Applications of 4J29 Alloy Rods

User Demands and Requirements

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.