Precision-Cut Inconel 625 Sheet – Ideal for Aerospace & Marine Applications

We offer factory direct pricing and special discounts for bulk orders. Whether you need small or large quantities, our products are shipped quickly to ensure a reliable supply for industrial projects worldwide.

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

-

Aerospace: Inconel 625 is extensively used in the aerospace industry, particularly for components exposed to high temperatures and extreme environments. This includes gas turbine engines, exhaust systems, and parts of aerospace engines. The alloy's ability to withstand high pressure and temperatures makes it suitable for turbine blades and exhaust systems.

-

Marine: Inconel 625 is highly resistant to corrosion and erosion, making it ideal for marine environments, including ship exhaust systems, propeller shafts, and seawater-cooled heat exchangers. Its resistance to pitting and crevice corrosion, especially in saltwater environments, enhances its longevity and reliability in marine applications.

-

Chemical Processing: Inconel 625's resistance to acids and high temperatures makes it a prime candidate for use in chemical reactors, piping, and other equipment in the chemical processing industry. It is especially effective in environments with sulfuric acid, phosphoric acid, and other aggressive chemicals.

- UNS N06625: The standard grade used for most high-temperature and high-stress applications.

- AMS 5599: A high-strength variation, often used in aerospace applications due to its superior mechanical properties.

- DIN 2.4856: The European designation for Inconel 625, offering a similar composition to UNS N06625.

- Melting and Casting: The alloy is melted in an electric arc furnace, followed by casting into ingots or billets.

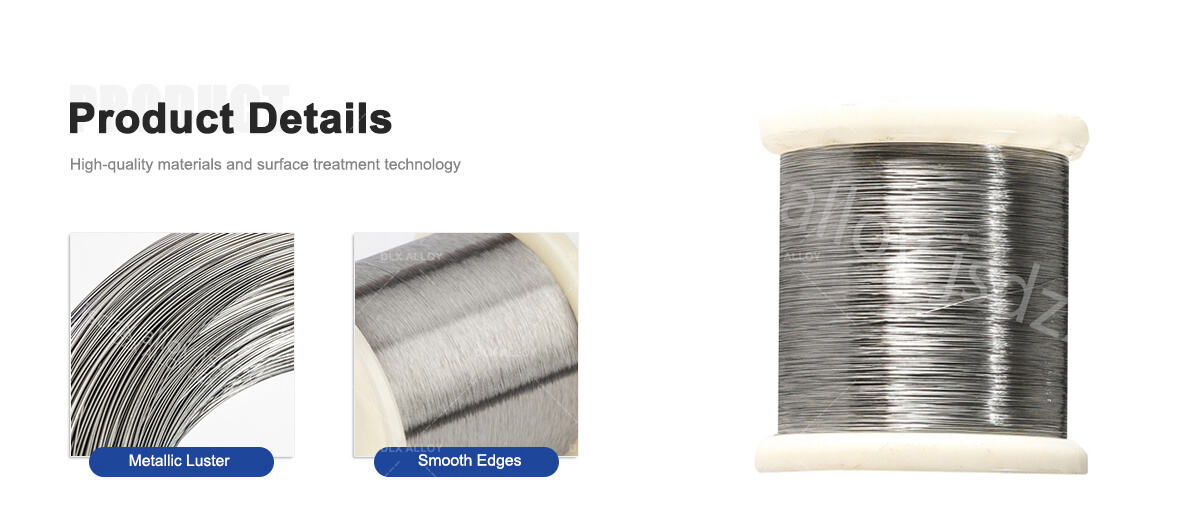

- Hot Rolling and Cold Rolling: The billets are hot rolled into plates or sheets, and subsequent cold rolling is performed to achieve precise thickness and smooth surface finish.

- Precision Cutting: Precision cutting techniques, such as laser cutting, water jet cutting, or CNC machining, are employed to produce sheets with accurate dimensions and tight tolerances.

- Heat Treatment: Heat treatment processes, including annealing, are used to relieve stresses and ensure optimal mechanical properties.

- Inspection and Quality Control: Rigorous inspections, including ultrasonic testing and X-ray inspections, are carried out to ensure the integrity and performance of the material.

- High Temperature Resistance: Aerospace and marine applications often involve exposure to extreme temperatures, so users demand materials that can perform reliably under high thermal stresses.

- Corrosion Resistance: Both saltwater environments in marine applications and harsh chemical environments in aerospace require materials with excellent resistance to oxidation, pitting, and crevice corrosion.

- Strength and Durability: The material must possess superior strength at both room and elevated temperatures, particularly for components subjected to high mechanical stresses, such as turbine blades and exhaust systems.

- Precision and Dimensional Accuracy: Since Inconel 625 is used in highly specialized applications, precise cutting, and consistency in dimensions are critical to ensure seamless integration into complex assemblies.

- Formability: Despite its high strength, Inconel 625 must also be formable to meet the demands of intricate designs required in aerospace and marine industries.

Introduction to Inconel 625 Material

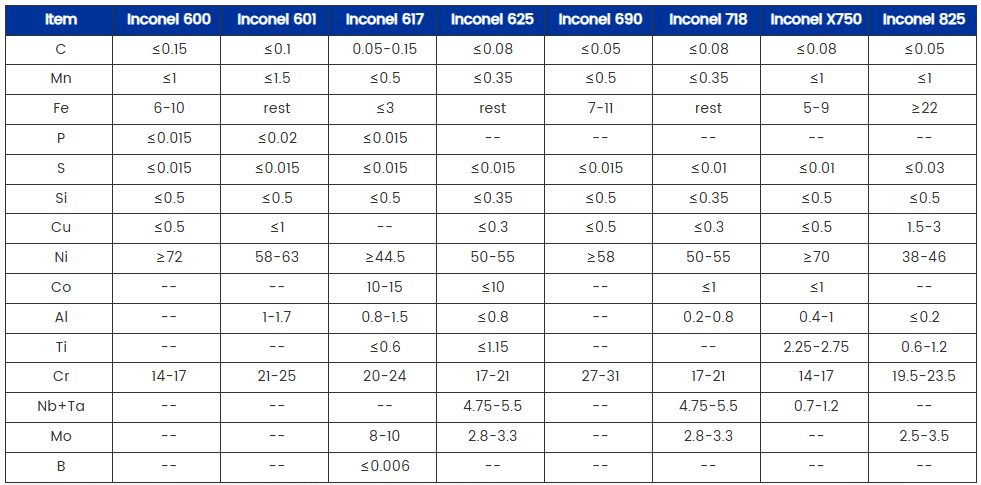

Inconel 625 is a high-performance nickel-chromium alloy known for its excellent resistance to high-temperature oxidation, corrosion, and fatigue. It is particularly useful in extreme environments where both high strength and resistance to chemical degradation are essential. Composed primarily of nickel (58%), chromium (20-23%), and molybdenum (8-10%), Inconel 625 is ideal for aerospace, marine, and other high-stress industrial applications.

Applications of Inconel 625

Inconel 625 is widely used in sectors such as aerospace, marine, and chemical processing, owing to its outstanding properties. Some of its key applications include:

Grade & Specifications

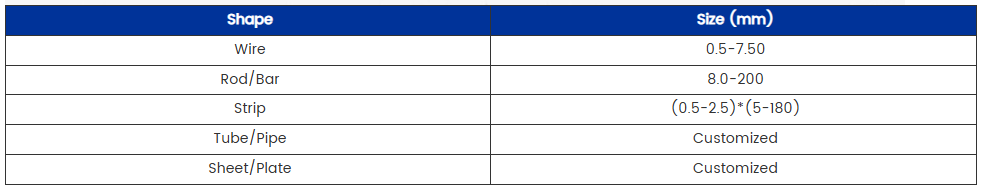

Inconel 625 is available in various forms, including sheet, plate, tube, and wire, with precision-cut sheets being one of the most popular forms due to their versatility in manufacturing processes. The material is typically offered in multiple grades, which can differ in their precise chemical composition to suit specific engineering applications. The most common grades of Inconel 625 include:

Manufacturing Process

The manufacturing of Inconel 625 sheets involves several steps, ensuring the precision and quality necessary for demanding applications. These steps include:

User Requirements

When selecting Inconel 625 for aerospace and marine applications, users typically prioritize the following factors:

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.