Plata N4 czysty nikkel 0,5mm-5mm | Odporna na kwaśne i zasadowe środowiska | Hurtownia fabryczna

Ofiarowujemy ceny fabryczne oraz specjalne rabaty dla zamówień hurtowych. Czy potrzebujesz małych czy dużych ilości, nasze produkty są dostarczane szybko, aby zapewnić niezawodne zaopatrzenie dla projektów przemysłowych na całym świecie.

- Przegląd

- Specyfikacja

- Zastosowania

- Najczęściej zadawane pytania

- Polecanie produkty

Płytka N4 z czystego niklu to materiał premium zawierający ≥99,5% niklu, znany z doskonałej odporności na kwaśniki, zasady i ekstremalne warunki środowiskowe. Ten materiał jest szeroko stosowany w przemyśle tam, gdzie wymagana jest wysoka odporność na korozję, przewodnictwo elektryczne oraz stabilność termiczną.

Produkowane za pomocą zaawansowanych procesów walcowania, wybielania i precyzyjnego cięcia, nasze płytki niklowe są dostępne w grubościach od 0,5 mm do 5 mm, z dostosowywalnymi rozmiarami spełniającymi różnorodne potrzeby przemysłowe. Zgodne ze standardami ASTM B162 i GB/T 2054-2005, nasze płytki niklowe N4 zapewniają niezawodną wydajność i długotrwałą trwałość.

Proces produkcji

Wybór surowca:

Wysokoczysty nikkel pochodzi z zaufanych źródeł i jest sprawdzany pod kątem zgodności ze standardami branżowymi.

Walcowanie ciepłe i zimne:

Nikkel przechodzi przez walecogniki pracujące przy wysokiej temperaturze, aby osiągnąć pożądaną grubość.

Walcowanie zimne zapewnia dokładność wymiarową i gładką powierzchnię.

Proces wybielania:

Materiał poddawany jest obróbce cieplnej w celu poprawy właściwości mechanicznych i wytrzymałości na wydłużanie.

Cięcie i Dobowy Końcowy:

Precyzyjne techniki cięcia (cięcie laserowe, obróbka CNC) zapewniają wymiary na zamówienie.

Powierzchnia jest obrabiana, aby zapewnić odporność na utlenianie i gładkość.

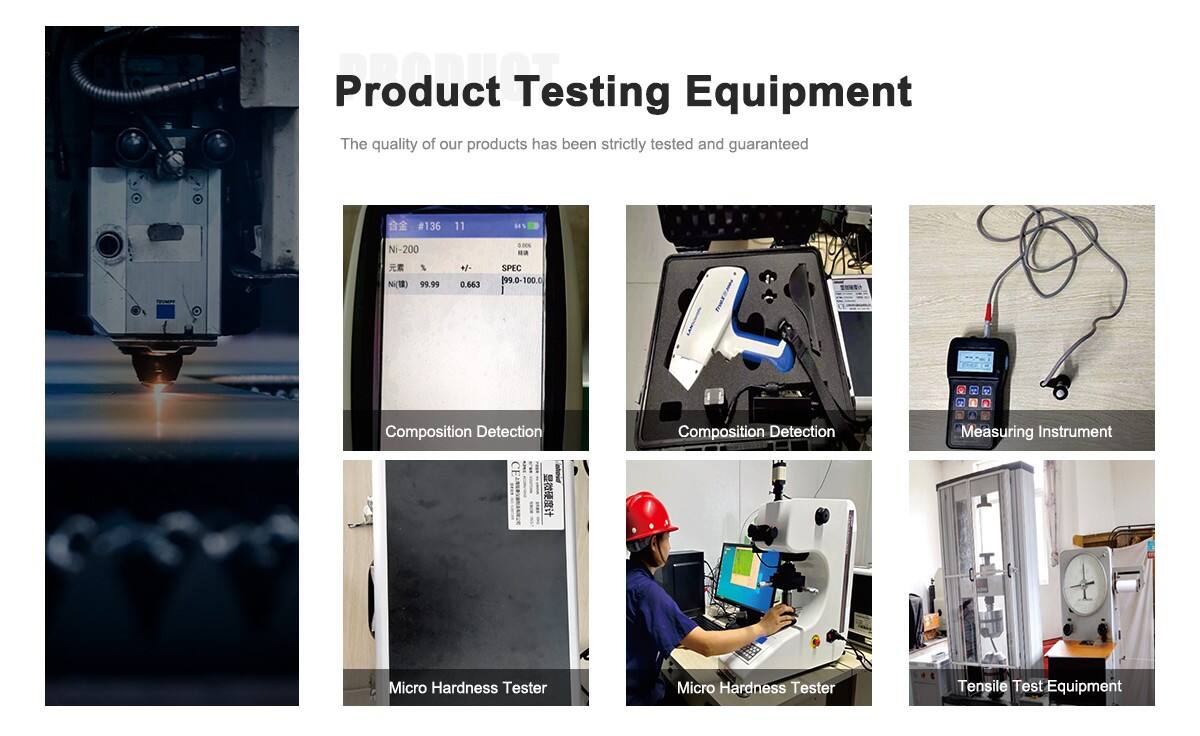

Kontrola Jakości i Testy:

Każda płyta jest testowana pod kątem czystości, wytrzymałości mechanicznej i odporności na korozję przed wysyłką.

Potrzeby Użytkownika i Zastosowania Przemysłowe

1. Przemysł Chemiczny

Używany w urządzeniach odpornych na kwaśne i zasadowe środowiska, zbiornikach magazynowych i rurociągach.

Gwarantuje długoterminową trwałość w surowych warunkach chemicznych.

2. Przemysł elektryczny i baterii

Wysoka przewodność elektryczna sprawia, że jest nadająca się do elementów baterii i płyt przewodzących.

Zastosowana w systemach magazynowania energii, łącznikach baterii litowo-jonowych oraz obwodach elektronicznych.

3. Lotnictwo i inżynieria morska

Idealna dla elementów samolotów, wymienników ciepła i zastosowań stoczniowych.

Odporna na korozję warunków morskich i środowiska o wysokich temperaturach.

4. Przemysł i precyzyjne obróbki mechaniczne

Używana do niestandardowych części metalowych, elektrod spawalniczych i konstrukcji mechanicznych.

Łatwo obrabiana, spawana i wykonywana, aby spełniać określone wymagania inżynierskie.

5. Wygenerowanie energii i wymienniki ciepła

Często stosowane w elektrowniach jądrowych, kondensatorach i systemach zarządzania cieplnym.

Gwarantuje wysoką przewodność cieplną i wytrzymałość mechaniczną.

| Specyfikacja | Szczegóły |

|---|---|

| Materiał | N4 (≥99.5% Czysty Nikl) |

| Zakres grubości | 0.5mm – 5mm |

| Szerokość | 100mm – 2000mm |

| Długość | Dostosowalne |

| Gęstość | 8.89 g/cm³ |

| Temperatura topnienia | 1435°C (2615°F) |

| Wytrzymałość na rozciąganie | ≥400 MPa |

| Metody przetwarzania | Walcenie, Wytapianie, Cięcie, Obróbka Powierzchni |

| Zgodność ze standardami | ASTM B162, GB/T 2054-2005 |

Dlaczego wybrać naszą płytę z czystego niklu N4?

Opcje dostosowywania:

Dostępne w różnych grubościach, szerokościach i długościach.

Obróbka CNC, precyzyjne obrabiarki oraz możliwość produkcji na zamówienie.

Wysokiej jakości produkcja:

Nowoczesne techniki walcowania i wybielania zapewniają wyższy poziom wydajności materiału.

Szczegółowe testy kontroli jakości gwarantują chemiczną czystość i mechaniczną wytrzymałość.

Duże dostawy & szybka dostawa:

Ceny fabryczne z rabatami hurtowymi dla dużych zamówień.

Dostawy na całym świecie za pomocą niezawodnych partnerów logistycznych zapewniają punktualną dostawę.

/Pytania często zadawane:

Jak długo to potrwa?

Zależy od ilości zamówienia, 10-30 dni dla małych zamówień. Dla dużych zamówień trwa to 60 dni.

Czy akceptujecie produkcję OEM/ODM?

Tak! Akceptujemy produkcję OEM/ODM. Możecie nam przesłać swoje próbki lub rysunki.

Jak kontrolujecie jakość swoich produktów? Czy właściwości chemiczne produktów spełniają standardy jakości?

Dzięki profesjonalnemu zespołowi ds. jakości, zaawansowanemu planowaniu jakości produkcyjnej, surowej realizacji i ciągłej poprawie wydajemy certyfikat inspekcji jakości produktów, w tym raport analizy chemicznej.

Czy wasza firma może dostarczyć szczegółowe dane techniczne i rysunki?

Tak, możecie. Prosimy o informację o produktach i zastosowaniach, które potrzebujecie, a my wyślemy wam szczegółowe dane techniczne i rysunki do oceny i potwierdzenia.

Jak obsługujecie sprzedaż przed i po zakupie?

Mamy profesjonalny zespół handlowy, który będzie pracował jeden do jednego, aby chronić Wasze potrzeby produkcyjne, a jeśli macie jakiekolwiek pytania, on na nie odpowie!

Czy mogę odwiedzić waszą fabrykę przed złożeniem zamówienia?

Tak, zapraszamy do odwiedzenia naszej fabryki. Miło nam mieć okazję poznać się wzajemnie.

Gdzie znajduje się wasza baza produkcyjna?

Produkujemy nasze produkty w Jiangsu, w Chinach, a następnie przesyłamy je z Chin do waszego kraju jak najszybciej, co zwykle zależy od wymagań dotyczących produktu i ilości.

Możesz wysłać próbki?

Tak, możemy.