Corrosiebestendige Hastelloy C-22 Buizen - Langdurig & betrouwbaar

Wij bieden fabrieksrechtstreekse prijzen en speciale korting voor groothandelbestellingen. Of u nu kleine of grote hoeveelheden nodig heeft, onze producten worden snel verzonden om een betrouwbare levering te waarborgen voor industriële projecten over de hele wereld.

- Overzicht

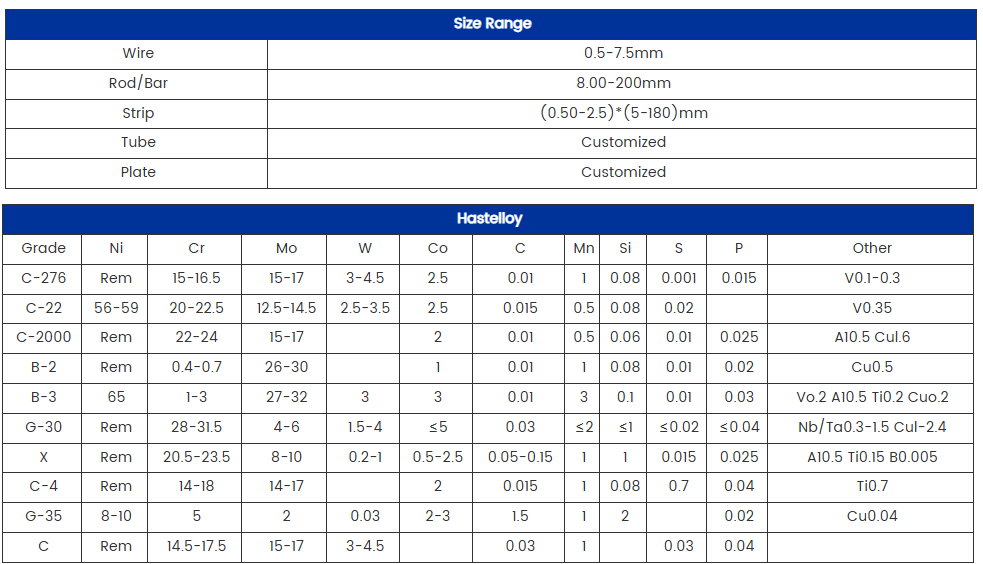

- Specificatie

- Toepassingen

- Veelgestelde vragen

- Aanbevolen Producten

-

Nikkel (Ni): Rest

-

Chroom (Cr): 20,0-22,5%

-

Molybdeen (Mo): 12,5-14,5%

-

Ijzer (Fe): 2,0-6,0%

-

Cobalt (Co): ≤ 2,5%

-

Tungsten (W): 2,5-3,5%

-

Koolstof (C): ≤ 0,015%

-

Mangaan (Mn): ≤ 0,50%

-

Silicium (Si): ≤ 0,08%

-

Zwavel (S): ≤ 0,02%

-

Uitzonderlijke corrosiebestendigheid: Verzet pitten, kruipcorrosie en spanningsscheurreuking in hoog agressieve omgevingen.

-

Hoge sterkte en duurzaamheid: Kan extreme temperaturen en mechanische spanningen verdragen zonder structuurintegriteit te compromitteren.

-

Veelzijdige toepassingen: Geschikt voor zowel oxidatieve als reductieve media, wat het zeer aanpasbaar maakt aan verschillende industriële processen.

-

Duurzaamheid en kostenbesparing: Verlaagt onderhouds- en vervangingskosten dankzij zijn uitstekende weerstand tegen verslechtering.

-

Chemische verwerking: Ideaal voor het vervoer van agressieve chemicaliën, waaronder hydrochloriczuur, zwavelzuur en chloorverbindingen.

-

Farmaceutische industrie: Gebruikt in geneesmiddelenproductieprocessen waarbij een verontreinigingsvrije omgeving essentieel is.

-

Kerncentrales: Toepassing in roetgaskwalificatiesystemen, warmtewisselaars en condensators.

-

Luchtvaart & Maritiem: Bestand tegen zoutwatercorrosie, wat het geschikt maakt voor offshore platforms en luchtvaartonderdelen.

-

Afvalwaterbehandelfaciliteiten: Zorgt voor veilig afhandelen van zuurhoudend en toxisch afvalmateriaal.

-

Rauwmateriaalselectie: Premium-grade Hastelloy C-22 legering wordt gebruikt.

-

Buisvorming: Buiswordt gefabriceerd door extrusie of naadloze methoden voor verbeterde sterkte en uniformiteit.

-

Warmtebehandeling: Oplossings-annealing wordt uitgevoerd om mechanische eigenschappen en corrosiebestendigheid te verbeteren.

-

Oppervlaktebewerking: Buizen ondergaan zuurbehandeling en passivering om onreinigheden te verwijderen en de levensduur te verbeteren.

-

Kwaliteitscontrole: Inclusief hydrostatische, ultrageluidse en chemische analyses om naleving van ASTM B622 en ASTM B619 standaarden te waarborgen.

-

Aanpassing: Beschikbaar in verschillende maten, diktes en specificaties om industriële behoeften te voldoen.

-

Groothandel & Fabrieksrechtstreekse Prijs: Zorgt voor kosteneffectiviteit voor grote projecten.

-

Wereldwijde Beschikbaarheid: Betrouwbare distributienetwerken voor snelle levering over de hele wereld.

-

Naleving van Branchestandaarden: Voldoet aan internationale voorschriften voor veiligheid en prestaties.

Hastelloy C-22 buizen worden breed erkend om hun uitzonderlijke corrosiebestendigheid en duurzaamheid, waardoor ze een voorkeurskeuze zijn voor industrieën die langdurige en betrouwbare materialen nodig hebben. Gemaakt van een nikkelgebaseerd legering bieden deze buizen superieure weerstand tegen oxidatie- en reducerende omgevingen, wat een uitstekende prestatie garandeert in strenge industriële toepassingen.

Hastelloy C-22 (UNS N06022) is een hoogwaardige nikkel-chroom-molybdeenlegering met verbeterde weerstand tegen verschillende vormen van corrosie. Het is bijzonder effectief in omgevingen met sterke oxidatoren, reducerende stoffen en lokale corrosiefactoren.

Chemische samenstelling:

Belangrijkste Kenmerken en Voordelen

Toepassingen van Hastelloy C-22 Buizen

Hastelloy C-22 buizen worden breed gebruikt in industrieën waar hoge corrosiebestendigheid cruciaal is. Enkele belangrijke toepassingen zijn:

Vervaardigingsproces

De productie van Hastelloy C-22 buizen omvat strikte kwaliteitscontrole en precisietechniek:

Marktvraag en klanteneisen

Vragen:

Hoe lang duurt de levering?

Het hangt af van de hoeveelheid van de bestelling, 10-30 dagen voor kleine bestellingen. Voor grote bestellingen duurt het 60 dagen.

Accepteert u OEM/ODM productie?

Ja! We accepteren OEM/ODM productie. U kunt ons uw monsters of tekeningen sturen.

Hoe controleert u de kwaliteit van uw producten? Voldoen de chemische eigenschappen van de producten aan de kwaliteitsnormen?

Met een professioneel kwaliteitsteam, geavanceerd productkwaliteitsplanning, strikte uitvoering en continue verbetering, zullen we een productkwaliteitscontrolecertificaat uitgeven, inclusief een chemisch analyserapport.

Kan uw bedrijf gedetailleerde technische gegevens en tekeningen verstrekken?

Ja, dat kan. Laat ons weten welke producten en toepassingen u nodig heeft, en wij zullen u gedetailleerde technische gegevens en tekeningen sturen voor uw evaluatie en bevestiging.

Hoe behandelen jullie voorkoop- en nasverkoopdiensten?

We hebben een professioneel zakenteam dat een-op-een met u samenwerkt om uw productbehoeften te beschermen, en als u vragen hebt, kan hij ze voor u beantwoorden!

Kan ik je fabriek bezoeken voordat ik een bestelling plaats?

Ja, je bent van harte welkom om onze fabriek te bezoeken. We zijn blij met de kans elkaar te leren kennen.

Waar is je productiebasis?

We produceren onze producten in Jiangsu, China en verzenden ze zo snel mogelijk vanuit China naar jouw land, wat doorgaans afhankelijk is van jouw producteisen en hoeveelheid.

Kun je monsters sturen?

Ja, dat kunnen we.