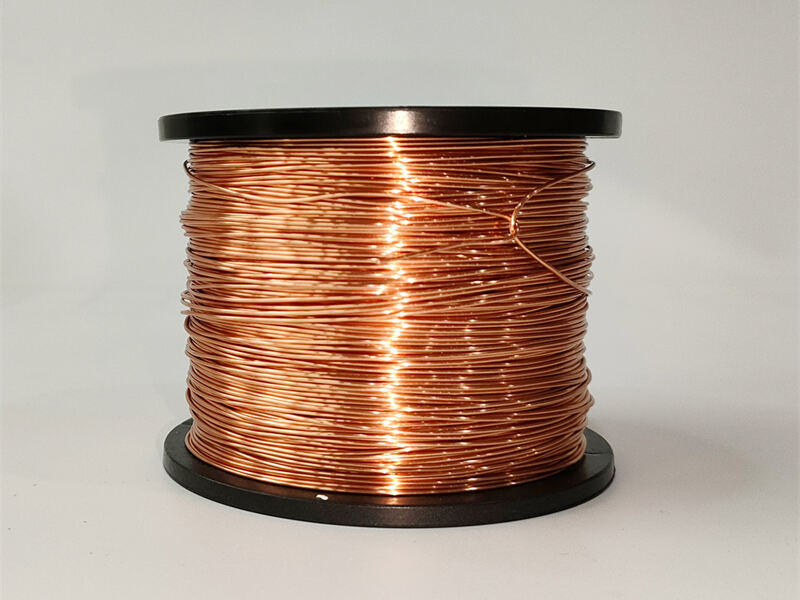

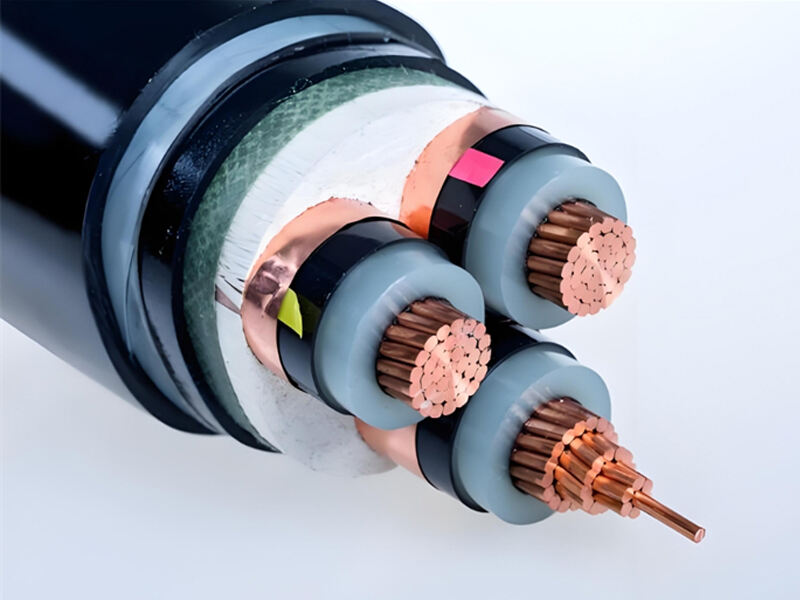

Uitmuntende elektrische geleidbaarheid:

Koper is een van de beste geleidingsmaterialen na zilver en wordt breed gebruikt in de elektriciteits- en elektronica-industrie.

Goede thermische geleidbaarheid:

De hoge thermische geleidbaarheid maakt het ideaal voor radiatoren, verwarmingselementen, etc.

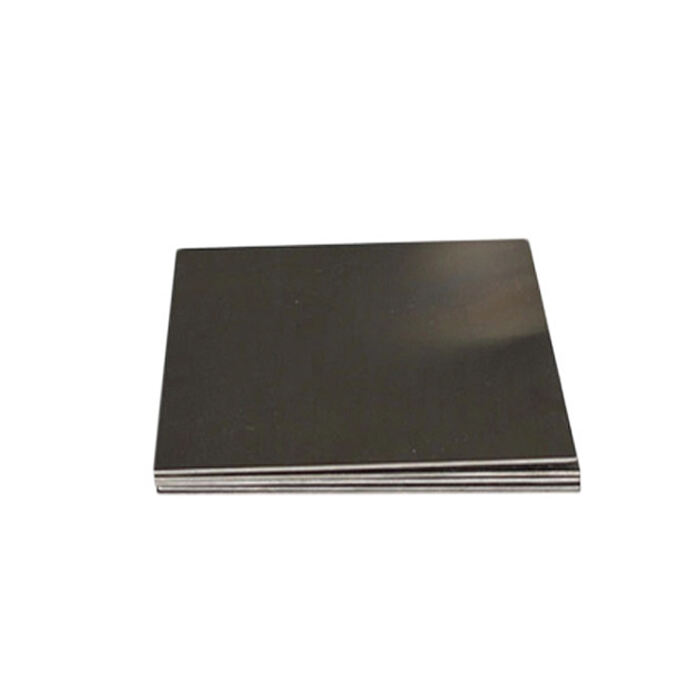

Corrosiebestendigheid:

Uitermate goed in zoetwateromgevingen, geschikt voor waterleidingen, koelsystemen, etc.

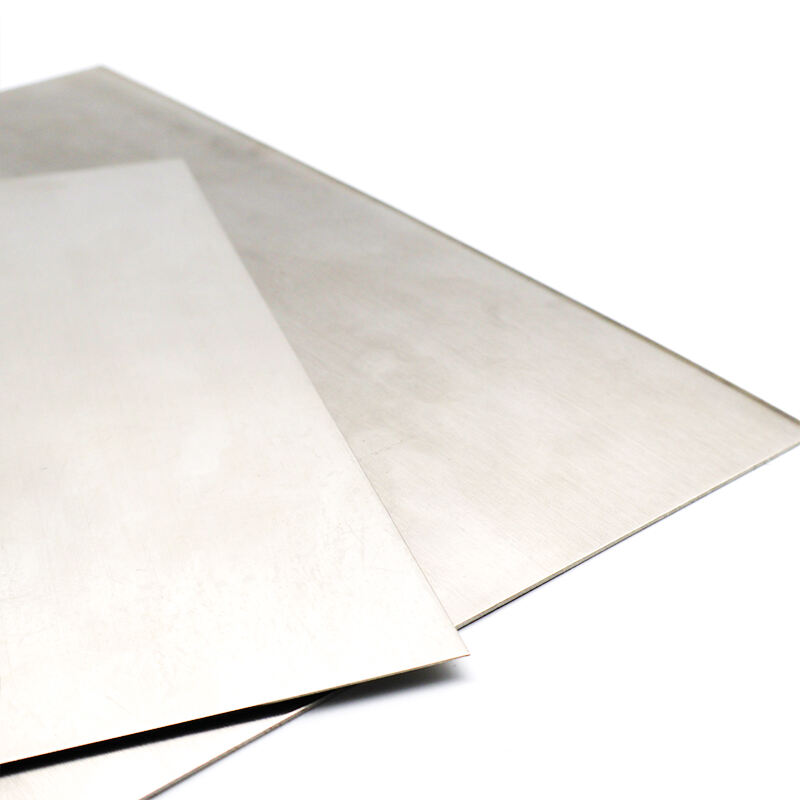

Machinaal verwerken en lassen:

Gemakkelijk te verwerken bij warm- en koudverwerking, vormen, lassen en brasen, gemakkelijk om complex gevormde producten te fabriceren.

Mooie uitstraling:

Met goede polijste en coating mogelijkheden, geschikt voor decoratieve doeleinden.

Biologische inhiberende eigenschappen:

Koper en zijn legeringen hebben een natuurlijk antibacteriële werking op vele micro-organismen en kunnen worden gebruikt in openbaar gezondheidsfaciliteiten.