Nimonic 90 Spring Wire for High-Temperature and High-Stress Applications

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

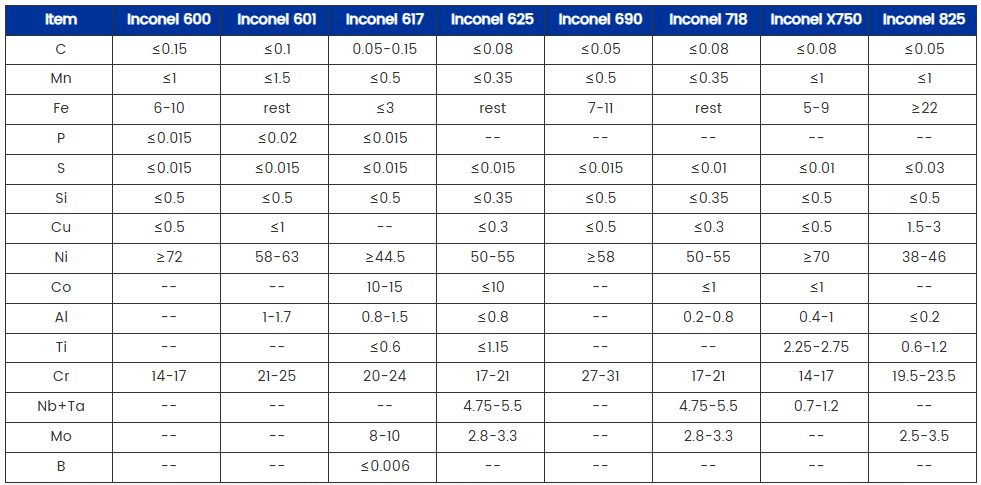

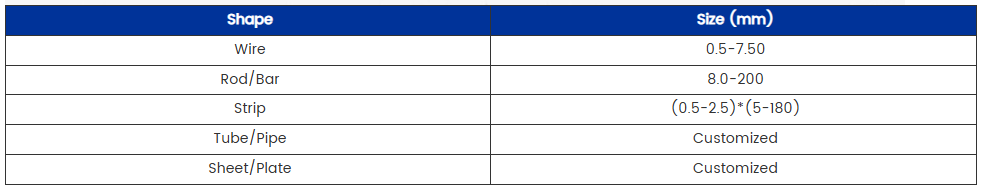

- Specification

- Applications

- FAQs

- Recommended Products

-

Outstanding High-Temperature Strength: Maintains tensile strength up to 800°C (1472°F), significantly outperforming standard spring steels

-

Excellent Creep Resistance: Withstands prolonged exposure to stress at high temperatures without deformation

-

Superior Fatigue Life: Exhibits remarkable resistance to cyclic loading in thermal-mechanical fatigue conditions

-

Oxidation and Corrosion Resistance: Chromium content provides protection against oxidation and hot gas corrosion

-

Precipitation Hardening Capability: Can be heat treated to achieve optimal strength and hardness characteristics

-

Good Fabricability: Can be cold drawn into precise wire diameters while maintaining its superior properties

-

Turbine blade retaining springs requiring long-term reliability at extreme temperatures

-

Afterburner components in military aircraft engines

-

Exhaust system springs for high-performance aircraft

-

Gas turbine valve springs in power plants

-

Nuclear reactor components requiring radiation resistance

-

High-temperature fasteners for steam turbine applications

-

Turbocharger springs in high-performance vehicles

-

Exhaust valve springs for racing engines

-

Thermal management system components in electric vehicle batteries

-

Furnace and heat treatment equipment springs

-

Chemical processing components resistant to corrosive environments

-

Oil and gas downhole tools for extreme service conditions

-

Increasing turbine inlet temperatures in modern jet engines and power generation systems

-

Growing demand for materials capable of withstanding more extreme operating conditions

-

Replacement of heavier components with high-strength, lightweight superalloys

-

Development of more efficient engine designs requiring advanced materials

-

Rising demand for high-efficiency power generation systems

-

Increased focus on renewable energy technologies requiring durable materials

-

Growing use of Nimonic 90 in 3D-printed components for complex geometries

-

Development of specialized wire forms for additive manufacturing processes

-

Need for longer-lasting components to reduce maintenance and downtime

-

Requirements for materials that can operate in more aggressive environments

In extreme engineering environments where conventional materials fail, Nimonic 90 emerges as a superior nickel-chromium-cobalt alloy specifically engineered for high-temperature and high-stress applications. This precipitation-hardening superalloy offers exceptional mechanical properties at elevated temperatures while maintaining excellent corrosion resistance. This article examines the unique characteristics of Nimonic 90 spring wire, its critical applications across industries, and the evolving market trends driving its adoption.

Material Properties and Performance Advantages

Nimonic 90 demonstrates an exceptional combination of properties that make it ideal for demanding spring applications:

Key Industrial Applications

1. Aerospace and Jet Engines

2. Power Generation

3. Automotive Performance

4. Industrial Processing

Industry Trends Driving Demand

1. Advancements in Turbine Technology

2. Lightweighting in Aerospace

3. Energy Sector Expansion

4. Additive Manufacturing Integration

5. Stringent Environmental Regulations

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.