Hastelloy C-276 बेर्निक पाइपहरू – ग्राह्यणात्मक माध्यमहरूमा उत्कृष्ट प्रतिरोध

हामी फैक्टरी सधैँ किमत प्रदान गर्दछौं र थुप्रै ऑर्डरहरूका लागि विशेष छूट प्रदान गर्दछौं। चाहिए पनि थोरै वा बढी मात्राको, हाम्रा उत्पादन समयजगतै पठाइन्छ जसले विश्वभरका औद्योगिक परियोजनाहरूको लागि विश्वसनीय सप्लाई सुनिश्चित गर्दछ।

- अवलोकन

- विशेषता

- अनुप्रयोगहरू

- सोधिने प्रश्नहरू

- सिफारिस गरिएका उत्पादनहरू

परिचय

Hastelloy C-276 भयानक पर्यावरणहरूमा अपनो असाधारण कारोजीवी प्रतिरोधकताका लागि जानिने उच्च-प्रदर्शन निकेल-मोलिब्डेनम-क्रोमियम संगम हो। एकिक रूपमा Hastelloy C-276 पाइपहरू रसायन प्रसंस्करण, समुद्री अनुप्रयोगहरू र विद्युत संयन्त्रहरू जसले दृढ र विश्वसनीय पाइपिङ्ग समाधानहरूको आवश्यकता छ त्यहाँ व्यापक रूपमा उपयोग गरिन्छ। उनीहरूको ऑक्सीडाइजिंग र रिड्यूसिंग एजेन्टहरूमा अत्यधिक प्रतिरोधकता तीव्र तरल र गैसहरू प्रबंधन गर्न आदर्श विकल्प बनाउँछ।

सामग्रीको सारांश

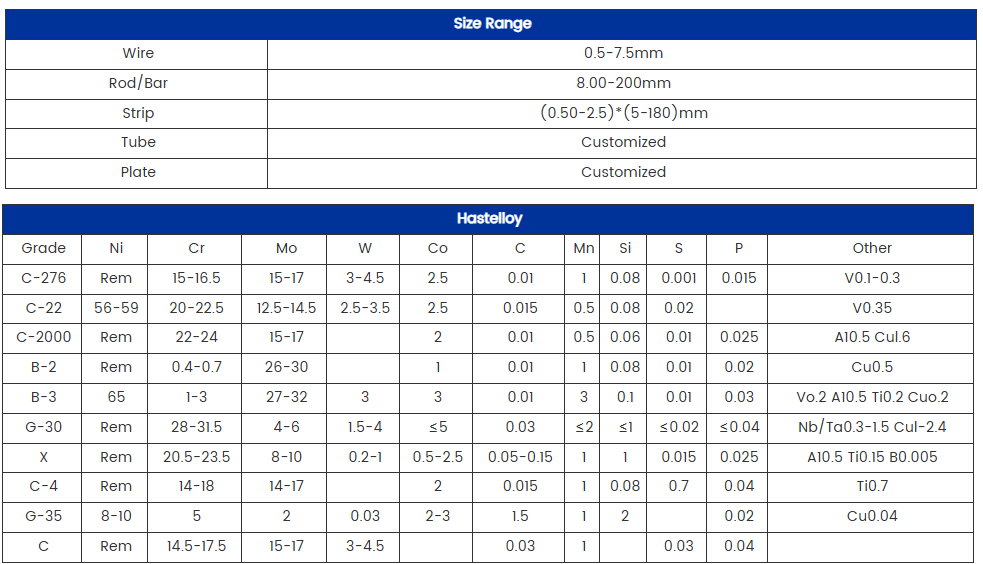

Hastelloy C-276 (UNS N10276) निकेल-आधारित संगम हो जसको निम्न रूपमा संघटना छ:

Nickel (Ni): 57% न्यूनतम

Molybdenum (Mo): 15-17%

Chromium (Cr): 14.5-16.5%

Iron (Fe): 4-7%

कोबाल्ट (Co): २.५% अधिकतम

टंगस्टन (W): ३-४.५%

अन्य तत्वहरू: मैनगनीज, सिलिकॉन, र कार्बनको छोटो मात्रा

यो संghन पिटिङ, क्रेविस कोरोशन, र स्ट्रेस कोरोशन crackingबाट धेरै प्रतिरोधी छ, जसले यसलाई अत्यधिक रासायनिक र उच्च तापमानको वातावस्थामा उपयुक्त बनाएको छ।

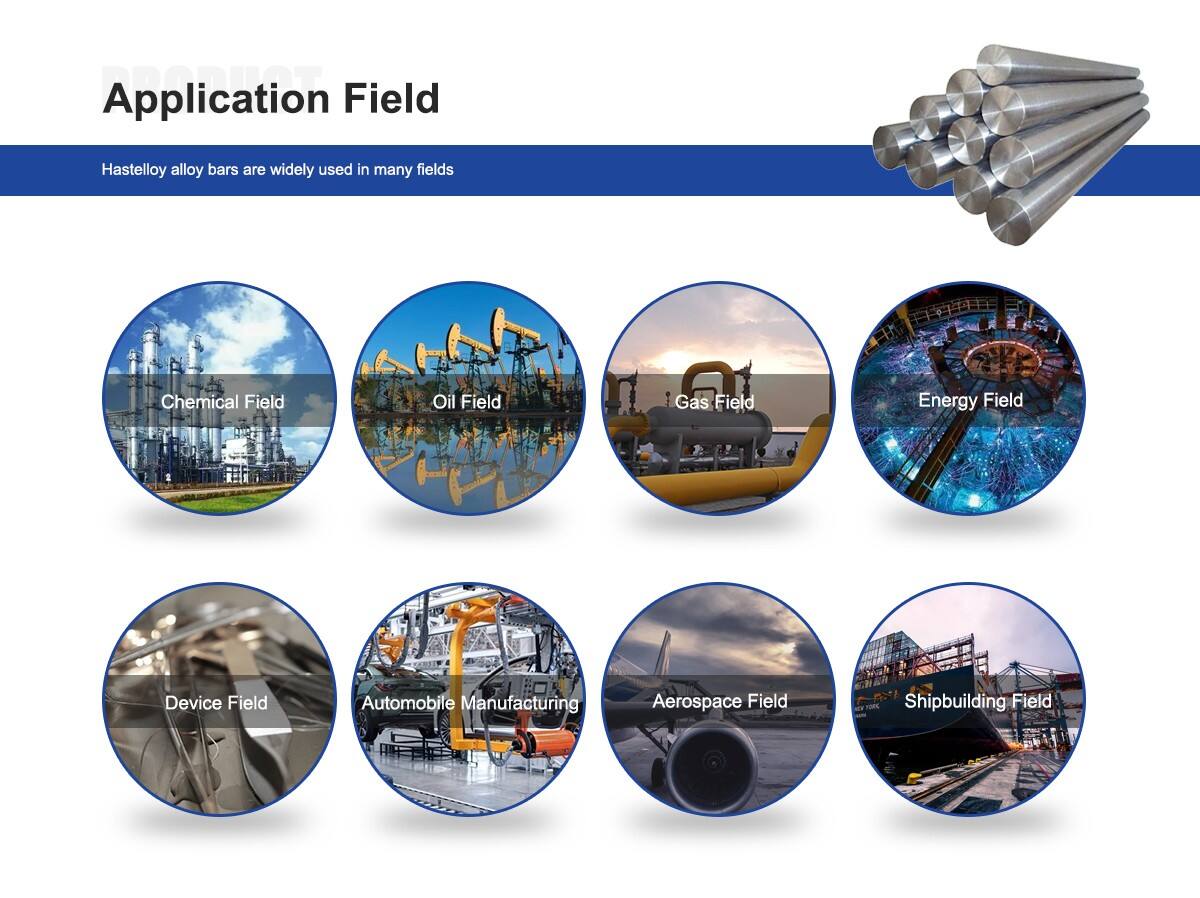

अनुप्रयोगहरू

Seamless Hastelloy C-276 पाइपहरू विभिन्न मागदमागी अनुप्रयोगहरूमा प्रयोग गरिन्छ, जसमध्ये छ:

रासायनिक प्रसंस्करण: सल्फ्युरिक अम्ल, हाइड्रोक्लोरिक अम्ल, र नाइट्रिक अम्लजस्ता अम्लजनक र कोरोशनको लागि रिएक्टरहरू, हिट एक्सचेञ्जरहरू, र पाइपिङ सिस्टमहरूमा प्रयोग गरिन्छ।

समुद्री उद्योग: यसको उत्कृष्ट साल्टवोटर कोरोशन र biofoulingबाट प्रतिरोधको कारण समुद्रिया पानीको पाइपिङ सिस्टमहरूमा आदर्श छ।

ऊर्जा केन्द्रहरू: उच्च तापमान प्रतिरोधको आवश्यकताका लागि flue gas desulfurization सिस्टमहरू, हिट recovery युनिटहरू, र superheatersमा प्रयोग गरिन्छ।

वायु र रक्षाकर्म: अत्यधिक वातावरणीय स्थितिहरूमा उच्च कोरोशन प्रतिरोधको आवश्यकताका लागि ईंधन र हाइड्रोलिक सिस्टमहरूमा लगाउन गरिन्छ।

फार्मास्यूटिकल र खाद्य प्रसेसिङ्ग: यसको विभिन्न रसायनहरू संग अप्रतिक्रिया भएको धेरै हुन्छ र उच्च शुद्धता मानदण्डहरू कारण लगायत प्रसेसमा प्रदूषण बाट बचाउँछ।

श्रेणीहरू र मानदण्डहरू

Hastelloy C-276 seamless pipes अनेक अन्तर्राष्ट्रिय मानदण्डहरूमा अनुरूप छन्, जसले गुणवत्ता र प्रदर्शन विश्वसनीयता प्रदान गर्दछ:

ASTM B622: निकेल एल्युमिनियम पाइप र ट्यूबको लागि निर्धारितकरण।

ASME SB622: ASTM B622 जसले बॉयलर र दबाव बर्तन अनुप्रयोगहरूको लागि तुलनीय छ।

DIN 17751: निकेल एल्युमिनियम पाइपहरूको जर्मन मानदण्ड।

EN 10216-5: निकेल-आधारित पाइपहरूको लागि यूरोपियन मानदण्ड।

ISO 6207: निकेल एल्युमिनियम पाइपहरूको लागि अन्तर्राष्ट्रिय मानदण्ड।

निर्माण प्रक्रिया

Seamless Hastelloy C-276 पाइपहरूलाई उच्च यांत्रिक शक्ति र धातुभित्ति प्रतिरोधको लागि विशेषज्ञ प्रोडक्शन प्रक्रिया गरिएको छ:

कच्चा सामग्री चयन: रसायनिक समानता बनाउन खाले निकेल एल्युमिनियम बिल्टहरू प्रयोग गरिन्छ।

एक्सट्रुशन र पियर्सिङ: बिलेटहरूलाई गरम गरीर र खोलेर कोणीय रूपमा रूपान्तरित गरिन्छ।

कोल्ड ड्राइंग र पिल्गरिङ: पाइपहरूलाई आवश्यक माप र मोटाइसम्म खिचिन्छ।

ऐनलिन: पाइपहरूलाई सबैभन्दा रसायनिक प्रतिरोध र यांत्रिक गुणहरूमा सुधार गर्न गर्मी प्रइलेटमा गरिन्छ।

पिकलिङ र पॅसिवेशन: अन्तिम सतह प्रइलेट लगाएर फिटो निकालिन्छ र ऑक्सीडेशन प्रतिरोधमा सुधार गर्दछ।

गुणस्तर परीक्षण: पाइपहरूलाई हाइड्रोस्टैटिक, अल्ट्रासोनिक र रासायनिक परीक्षणमा गर्ने गर्दछ जसले कठोर उद्योगी मानदण्डहरू पूरा गर्दछ।

मुख्य विशेषताहरू र लाभहरू

जोडीभन्दा बिना: कुनै वेल्डेड जोडीभन्दा बिना, जुन उच्च दबाव प्रतिरोध र एकसमान शक्तिमा परिणाम दिन्छ।

उत्कृष्ट कारोज्ञ रोध: दोनो ऑक्सीडेशन र रिडक्स परिवेशमा राम्रै प्रदर्शन गर्दछ।

उच्च तापमान शक्ति: १०००°सी सम्मको अत्यधिक तापमान बाट बच्न सक्ने।

दीर्घ सेवाकाल: त्यसको स्थिरता र भरोसामान्यले रखमान खर्च घटाउँछ।

उत्कृष्ट वेल्डिङ: अर्को निकेल यौगिकहरू र स्टेनलेस स्टीलहरूसँग आसानीसँग वेल्डिङ गर्न सकिन्छ।

निम्न कार्बन मात्रा: कार्बाइड चढ़ाहटलाई न्यूनीकरण गर्दछ, जसले अंतरग्रनीय धुंगालमा प्रवेश रोक्दछ।

ग्राहकको माग र बजारका रुझानहरू

Hastelloy C-276 अखण्ड पाइपहरूको माग बढ्दो निम्न कारणहरूले चालू गरिएको छ:

रसायनिक र पेट्रोरसायनिक उद्योग स्फीति: वैश्विक रसायनिक उत्पादन र रिफाइनरीहरूमा वृद्धि।

पर्यावरणीय नियमावलीमा अनुरूपता: प्रदूषण नियन्त्रण प्रणालीहरूमा जस्तै धुम्रगैस डिसल्फराइजेसनमा प्रयोगको वृद्धि।

पुनर्जीवनशील ऊर्जा परियोजनाहरू: भूतापीय र बायोफ्युएल प्रसंस्करण प्लांटहरूमा अपनाइने।

उपसागरीय तेल र गैस खोज: गहिराइ बियानमा पाइपिङ्गको लागि उच्च प्रदर्शनको आवश्यकता।

निष्कर्ष

Hastelloy C-276 अखण्ड पाइपहरू अत्यधिक धुंगाली र चरम परिवेशमा अपरिहार्य प्रदर्शन प्रदान गर्दछन्। उनीहरूको उत्कृष्ट शक्ति, थाहिरात, र आक्रामक रसायनहरूमा प्रतिरोध उनीहरूलाई विश्वसनीय पाइपिङ्ग समाधानहरूको आवश्यकतामा उद्योगहरूका लागि प्राथमिक वैकल्पिक बनाएको छ। कारखानाबाट आगाजी प्रदान र प्रतिस्पर्धात्मक किमतमा, यी पाइपहरू दीर्घकालिन प्रदर्शन र लागत बचतको खोजमा व्यवसायहरूको लागि उत्कृष्ट निवेश हुन्।

सामान्य प्रश्नहरू:

कति समयसम्म वितरण हुन्छ?

यो अर्डरको मात्रापर निर्भर गर्छ, साना अर्डरहरूको लागि १०-३० दिन। ठूलो अर्डरहरूको लागि ६० दिन लाग्छ।

के तपाईं OEM/ODM उत्पादन स्वीकार्नुहुन्छ?

हो! हामी OEM/ODM उत्पादन स्वीकार्छौ। तपाईं हामीलाई तपाईंका नमूना वा ड्राइंगहरू पठाउन सक्नुहुन्छ।

तपाईं आफ्नो उत्पादहरूको गुणस्तर कसरी नियन्त्रण गर्नुहुन्छ? के उत्पादहरूको रासायनिक गुणस्तरहरू गुणस्तरको मानदण्डहरूमा मिल्दछ?

पेशागत गुणस्तरको संgh, अगाडी गई उत्पाद गुणस्तर योजना, कठोर प्रयोग र निरन्तर सुधारको साथ, हामी उत्पाद गुणस्तर परीक्षण प्रमाणपत्र जारी गर्छौं, जसमा रसायनिक विश्लेषण प्रतिवेदन समेत छ।

कम्पनी विस्तृत तकनीकी डेटा र ड्राइंगहरू प्रदान गर्न सक्छ?

हो, तपाईं गर्न सक्नुहुन्छ। कृपया तपाईंले जर्जर उत्पादहरू र अनुप्रयोगहरू बताउनुहोस्, र हामी तपाईंको मूल्याङ्कन र समर्थनको लागि विस्तृत तकनीकी डेटा र ड्राइंगहरू पठाउनेछौं।

तपाईं पूर्व-विक्री र पछाडी-विक्री सेवाहरू कसरी हाल्नुहुन्छ?

हामी एउटा पेशागत व्यापार संgh छ, जो तपाईंको उत्पाद आवश्यकताहरू रक्षण गर्न एक-एकै साथ काम गर्छ, र यदि कुनै प्रश्नहरू छन्, त्यो तपाईंलाई उनीहरूको जवाफ दिन सक्छ!

म आदेश दिनुभन्दा पहिले कम्पनी भिट्टी भेट्न सक्छु कि छ?

हो, तपाईंलाई हाम्रो भिट्टी भेट्न स्वागत छ। हामी सम्झाउनको अवसर प्राप्त गर्न खुशी छ।

तपाईंको उत्पादन आधारकाठी कहाँ छ?

हामी चीन, जियांगसुमा हाम्रो उत्पादहरू निर्माण गर्दछौं र तपाईंको देशमा चीनबाट त्यो जल्दै भेटाउँछ, जसले आम्तानी तपाईंको उत्पाद आवश्यकताहरू र मात्रा पर्दछ।

के तपाईं माइले नमूना पठाउन सक्नुहुन्छ?

हाँ, हामी पठाउन सक्छौं।