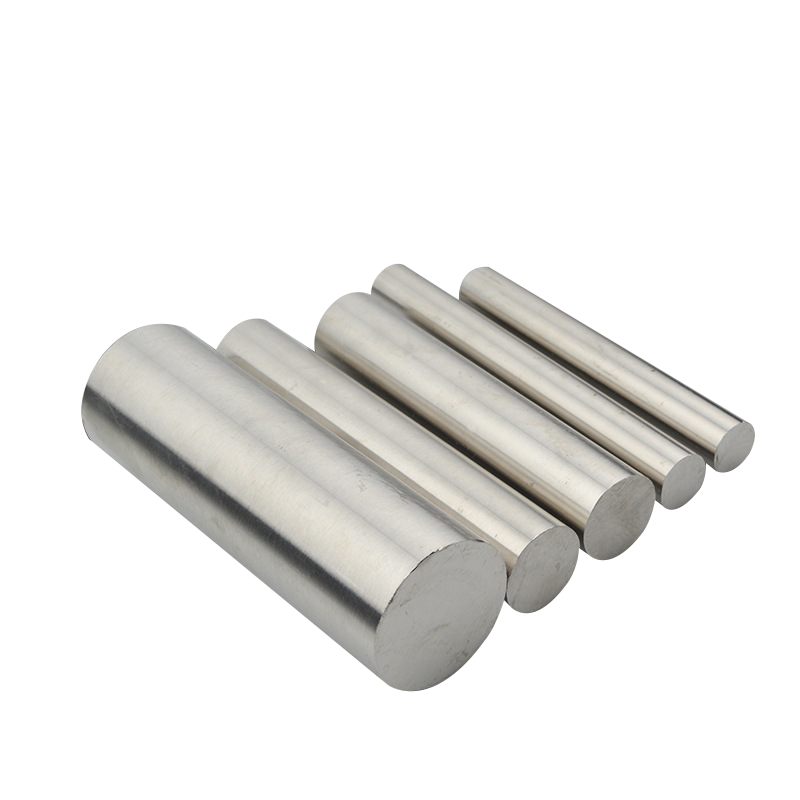

High-Strength Monel 400 Bars – Aerospace နှင့် Power Plants အတွက် ဒီဇိုင်းထုတ်ထားသော

ငါတို့ဟာ အဆက်မပြတ် စက်ရုံနှုန်းဖြစ်သော စျေးနှုန်းများနှင့် အရေအတွက်များအတွက် ထူးခြားသော ဒေသလိုက် ရှုံးထိန်းမှုများကို ပေးပါသည်။ သင့်အား အသေးစိတ်သို့မဟုတ် အကြီးမားသော အရေအတွက်များလိုအပ်ပါက၊ ကမ္ဘာ့အနောက်ဆုံး ឧုံပြုလုပ်ရေးလုပ်ငန်းများအတွက် ယာဉ်ကြီးသုံး ပণုံများကို အမြန်တိုးတက်စွာ ပို့ဆောင်ပေးပါသည်။

- အကျဉ်းချုပ်

- ဖော်ပြချက်

- အသုံးပြုမှုများ

- အမေးအဖြေများ

- အကြံပြုထားသော ထုတ်ကုန်များ

- Nickel (Ni): ≥ 63%

- Copper (Cu): 28-34%

- Iron (Fe): ≤ 2.5%

- Manganese (Mn): ≤ 2.0%

- Silicon (Si): ≤ 0.5%

- Carbon (C): ≤ 0.3%

- Sulfur (S): ≤ 0.024%

- လေယာဉ်အင်ဂျင်အစိတ်အပိုင်းများ၊ လေကြောင်းပစ္စည်းအစိတ်အပိုင်းများနှင့် ဖော်မြူရှင်းများအတွက် အသုံးပြုသည်။

- အမြင့်လေထုအဆင့်တွင် အပူချိန်ပြောင်းလဲမှုများနှင့် အတ္တိုက်ဆိုင်ရာသို့မဟုတ် အတ္တိုက်ကိရိယာများကို မီးဖြစ်စေခြင်း။

- ဒါမေးစစ်စနစ်များ၊ အာကာသပစ္စည်းများနှင့် လေယာဉ်ပိုင်ဆိုင်များတွင် အသုံးပြုသည်။

- အိုင်းပိုင်းတွင်းလေးများ၊ နိုးကွင်းရေးအစိတ်အပိုင်းများနှင့် အပူချိန်လေ့လာမှုများတွင် အသုံးပြုသည်။

- အပူချိန်မြင့်ရောင်းအား မျှဝေခြင်း၊ အရေဒီယာချိုးဖြတ်မှုနှင့် အပူချိန်အဆုံးဖြတ်အခြေအနေများကို ကာကွယ်ခြင်း။

- အရှည်ကြာသောအချိန်တာဝန်ဆိုင်ရာလုပ်ဆောင်မှုနှင့် ကျွမ်းကျင်မှုကို စျေးစေသည်။

- လှေတည်ဆောက်ရေး၊ ရေကိုယ်ပြောင်းရေးရုံများနှင့် လောင်းပြင်ထဲရှိ ဖျားထိုးစက်များအတွက် အဆင်ပြေပါသည်။

- ကျွန်သောက်ရေမှုပ္ပါတီကြောင်း၊ ဘီယူဖောင်လင်းနှင့် ရောင်းသောလောင်းပြင်ပတ်ဝန်းကျင်များကို မျှော်မည်။

- အရှည်ကြာသော တာဝန်ဆိုင်ရာ အသေးစိတ်များအားလုံးအတွက် လောင်းပြင်ရှားများ၊ ပရိုပျာလာများနှင့် ပိတ်ဆိုင်များတွင် အသုံးပြုသည်။

- အစိုးရောင်းနှင့် အကာလိုင်းဖြောင့်ဖြင့် လုပ်ဆောင်သည့် တိုက်များ၊ ပัмပ်များ၊ ပိုင်းခြားစနစ်များနှင့် ရောင်းတွင် အသုံးပြုသည်။

- ဟားဒရိုဂျင်ဖလူးဗေးအစိုး၊ ဆူးဖောင်အစိုးနှင့် ឧုံးလုပ်ငန်းသုံးစွမ်းရည်များကို မျှော်သည်။

- အပူချိုးစွာပြောင်းလဲမှုရုံများ၊ ကောင်ဒင်စာများနှင့် ဓာတ်ပုံဆိုင်ရာ ဆက်ထိုးဆောင်းပွဲတော်များတွင် အသုံးပြုသည်။

- လောင်းထဲတွင် ဖျားထိုးလုပ်ငန်းစဉ်များ၊ ပိုင်းခြားစနစ်များနှင့် ကျွန်းမှုဗိုလ်စာရင်းတွင် အသုံးပြုသည်။

- ဟားဒရိုဂျင်ဆူးဖောင် (H2S) နှင့် အားမြင်သော ဆူးရောင်းဂိုးပတ်ဝန်းကျင်များကို မျှော်သည်။

- အရှုပ်ထွေးသော ဆေးရွက်ထုတ်လုပ်ရေးအခြေအနေများတွင် ဖြစ်ပွားမှုအတွင်းပါဝင်သည်။

- မူလပစ္စည်းရွေးချယ်မှု: အဆင့်တကြီးသို့မဟုတ်သော 昳ီထိုင်များ၏ ပိုင်းဝဲများအတွက် Monel 400 အလီဂျာဘီလက်များကို အသုံးပြုသည်။

- ပူပြီး လှုပ်ရှားခြင်းနှင့် ဖိုးဂိတ်ခြင်း: အလီဂျာကို ပူပြီး လှုပ်ရှားသည် သို့မဟုတ် ဖိုးဂိတ်ခြင်းဖြင့် ဘားဖြောင်အဖြစ်ပြောင်းလဲသည်။

- အပူချိန်မှာ မက်ခ်နီကယ်အားဖြင့် ပိုင်းခြားခြင်းနှင့် အရွယ်အစားတိုးခြင်း: သိပ္ပံရေးအရ ပိုင်းခြားခြင်းဖြင့် အရွယ်အစားများကို မှန်ကန်စေရန် နှင့် မက်ခ်နီကယ်အားဖြင့် ပိုင်းခြားခြင်းကို တိုးတက်စေသည်။

- အပူချိန်ကို လှုပ်ရှားခြင်းနှင့် အန်နီလိုင်းခြင်း: အစိုးရမှု၊ ကားရောင်းမှုကို ကန့်သတ်ခြင်းနှင့် အသားတောင်းမှုကို တိုးတက်စေသည်။

- မျက်နှာပြင်ဆင်ခြင်း: ပြင်ဆင်ခြင်း၊ ပစ်ကိုင်ခြင်းနှင့် ပြောင်းလဲခြင်းဖြင့် အဆင့်တကြီးဆိုင်ရာ လုပ်ဆောင်ချက်များကို ပြုလုပ်သည်။

- အရိုးအတုအရှိန်စစ်ဆေးခြင်း: အိုင်းလျှို့ဝိုးစစ်ဆေးခြင်း၊ မက်ခ်နီကယ်အားဖြင့် အစိုးရမှုစစ်ဆေးခြင်းနှင့် အရွယ်အစားစစ်ဆေးခြင်းများကို ASTM B164 နှင့် ASME SB164 စ준များအတိုင်း လုပ်ဆောင်သည်။

- အမှတ်တံဆိပ်မှုများ: ကိုယ်ပိုင်အလိုအလျောက် အရွယ်အစားများ၊ အချင်းအလျားများနှင့် ပြင်ဆင်မှုများအတွက် ရရှိနိုင်သည်။

- အရေအတွက်အများအပြားမှုနှင့် ကုန်ပစ္စည်းအလိုက်အလျောက်မှု: ရုပ်ကျွဲတွင်းမှ ကုန်ပစ္စည်းကို ပေးဆောင်ခြင်းဖြင့် အဆင့်တကြီးအားဖြင့် အစိုးရအစားအားဖြင့် အကောင်းဆုံးအစားအားဖြင့် ပေးဆောင်သည်။

- အမျိုးသားချင်းစီး ကိုင်တွယ်မှု: လေထြန်း၊ အင်္ဂါအင်ပိုင်းနှင့် ရေပိုင်း ឧုံးစိုက်မှု ကုမ္ပဏီများအတွက် ကမ္ဘာလုံးဆိုင်ရာ qualité စ준များအတွက် ကိုင်တွယ်မှုရှိသည်။

- ကမ္ဘာလုံးတွင် ပို့ဆောင်ရေးမှူးများ: ကမ္ဘာလုံးတွင် မိမိရဲ့ အလွယ်တကူ ပို့ဆောင်မှုနှင့် သော့သော ပို့ဆောင်ရေးကို ချိုးဖော်သည်။

Monel 400 ဘားများသည် အထူးစွမ်းရည်များ၊ ကိုရိုးရေးတိုက်ခိုင်မှုနှင့် အပူချိန်ဆိုင်ရာလွတ်လပ်မှုဖြင့် လူသိများသော နီကယ်-ကပ်ပဲ alloys ဘားများဖြစ်သည်။ ဒီဘားများသည် အာကာသ၊ အင်္ဂါအင်အား၊ သင်္ဘောလုပ်ငန်းနှင့် ဓာတ်ပုံလုပ်ငန်းတွင် ကျော်လွှားစွာအသုံးပြုသည်။ အကြီးအကျယ်ပြင်ဆင်မှုများ၊ မြင်းအပူချိန်များနှင့် ကိုရိုးရေးအခြေအနေများကို မျှဝေခြင်းနှင့် အားပေးခြင်းဖြင့် Monel 400 ဘားများသည် အရေးကြီးသောအသုံးပြုမှုများတွင် ရှိနေသော အဆိုင်ရာအဆင်မြင်မှုအတွက် အဆင်ပြေပြီး အရွယ်အစားရှိသည်။

ဒေသအချက်အလက် – Monel 400 (UNS N04400)

Monel 400 သည် နီကယ် (≥63%) နှင့် ကပ်ပဲ (28-34%) ဖြင့် ဖွဲ့စည်းထားသော ပြောင်းလဲမှု alloy ဖြစ်ပြီး အစိုးရောင်းနှင့် အခြေခံပြင်ဆင်မှုများ၊ ကျောက်ရေကိုရိုးရေးနှင့် မြင်းအပူချိန် oxidation တို့ကို ကာကွယ်ပေးသည်။ ဒီပစ္စည်းသည် non-magnetic၊ အမြင်အရောင်းမြင်သော၊ လုပ်ဆောင်ခြင်းအားလုံးကို ပြုလုပ်နိုင်သည်။

Monel 400 ရဲ့ ဓာတ်ပူးတည်ဆောက်မှု

Monel 400 ဘားများ၏ အခြေခံဂုဏ်သတ္တိများ

✔ အင်တိုင်းမြင့်နှင့် ကျန်ထိုင်သည်: ရုပ်မှန်ကွပ်ကဲမှု၊ လော့ဒ်မြင့်ချိန်များနှင့် အဆုံးဖြတ်အခြေအနေများကို မျှဝေခြင်း။

✔ ကိရိယာမှုကို ကာကွယ်ရေး အားဖြင့် ကောင်းမွန်သည်: ကမ္ဘာ့ရေတွင်း၊ အစိမ်းရေနှင့် အပူချိန်မြင့်ပερာတွင် ကောင်းမွန်စွာ လုပ်ဆောင်သည်။

✔ အပူချိန်မြင့်စွာ လျှော့ချရေး အားဖြင့် ကောင်းမွန်သည်: အပူချိန်မြင့်တွင် လေ့လာသော လေယာဉ်များနှင့် အင်တာဗားစ်အတွက် အသုံးပြုသည်။

✔ မဟုတ်သော မီဂ္ဂန်နှင့် အပူချိန်မြင့် ဖြစ်ပွားမှု ကို ကာကွယ်သည်: အီလက်ထရောနစ်နှင့် လေယာဉ်များတွင် အကြံပြုအစိတ်အပိုင်းများအတွက် ပိုင်းခြားသည်။

✔ ကောင်းမွန်သော မူရင်းနှင့် ဆေးခြင်း: ပိုင်းခြားသော ပုံစံများနှင့် အရွယ်အစားများအဖြစ် ဖန်တီးရန် လွယ်ကူသည်။

Monel 400 ဘားများ၏ အသုံးပြုချက်များ

၁. လေယာဉ်တိုက်နှင့် လေထုပျံသွားမှု ឧစ္စာရေး

အင်အားရေးရုံများနှင့် အင်အားရေးအပိုင်း

3. သင်္ဘောနှင့် ရေထဲတွင်ရှိသော ឧုံပြုလုပ်ငန်း

4. Chemical & Petrochemical Processing

5. သံဃာနှင့် ဂိုးသံဃာ လုပ်ငန်း

Monel 400 ဘားများအား ထုတ်လုပ်ရေးလုပ်ငန်း

ဈေးကွက်တော်လှန်မှုနှင့် angganerအားလုံး၏ လိုအပ်ချက်များ

အဆင့်တကြီးသို့မဟုတ်သော ကားရောင်းမှုကို ကန့်သတ်နိုင်သော မီတာဘားများအတွက် တောင်းဆိုင်ရာ လိုအပ်ချက်များအတွက် Monel 400 ဘားများကို အသုံးပြုသည်။

FAQs:

ပို့ဆောင်မှု အချိန်က ဘယ်လောက်ကြာလဲ။

အမှားအယွင်း၏ ပမာဏပေါ်မူတည်၍၊ အသေးစိတ်မှာ 10-30 ရက်၊ အကြီးမားသော အမှားအယွင်းများအတွက် 60 ရက်လိုအပ်သည်။

OEM/ODM ထုတ်လုပ်မှုကို လက်ခံလာမလဲ?

ဟုတ်ပါတယ်! OEM/ODM ထုတ်လုပ်မှုကို လက်ခံလိုက်ပါတယ်။ သင့်ရဲ့ ตัวอย่างများ သို့မဟုတ် ရေးပုံတို့ကို ပို့ပေးနိုင်ပါတယ်။

သင့်ထုတ်ကုန်များ၏ qualité ကို ဘယ်လိုထိန်းသိမ်းလဲ? ထုတ်ကုန်များ၏ ဓာတ်ပုံအချက်အလက်များသည် အရည်အချင်းစီမံခန့်ခွဲခြင်းများကို ကိုက်ညီလာမလဲ?

ပညာရှင်အရည်အချင်းအသေးစိတ်အဖွဲ့၊ ရှုံးမြှင့်ထုတ်ကုန်အရည်အချင်းစီမံခန့်ခွဲမှု၊ ကြီးကြပ်ထိန်းသိမ်းမှုနှင့် ဆက်လက်ပြင်ဆင်မှုဖြင့်၊ ကျွန်ုပ်တို့သည် ထုတ်ကုန်အရည်အချင်းစစ်ဆေးရေးမှတ်ပုံတင်စာများကို ထုတ်ပေးပါမည်၊ ပါဝင်သည့် ဓာတ်ပုံအခွဲခြားစာရင်းကို ပါဝင်သည်။

ကိုယ့်ကုမ္ပဏီဟာ ရှုံးလွန်သော teknical ဒေတာများနှင့် ရေးဆွဲမှုများကို ပေးနိုင်ပါသလား။

ဟုတ်ပါတယ်၊ ပေးနိုင်ပါတယ်။ လိုအပ်သည့် ထုတ်ကုန်များနှင့် အသုံးပြုမှုများကို ကျွန်ုပ်တို့အား ပြောပြပါ။ ကျွန်ုပ်တို့သည် သင့်အတွက် ရှုံးလွန်သော teknical ဒေတာများနှင့် ရေးဆွဲမှုများကို ပေးပို့ပါမည်။

သင့်တို့သည် ရောင်းချမှုအတွင်းနှင့် ရောင်းချပြီးနောက် ဝန်ဆောင်မှုကို ဘယ်လိုလုပ်ဆောင်သည်။

ကျွန်ုပ်တို့၏ ပို့စ်ဖွဲ့အဖွဲ့တစ်ဦးတည်းသည် သင့်ထုတ်ကုန်လိုအပ်ချက်များကို ကာကွယ်ပေးမည်ဖြစ်ပြီး မေးခွန်းများရှိလျှင် သူသည် အဖြေပေးနိုင်ပါသည်။

အမှတ်တံဆိပ်ပေးမှုကို ရှာဖွေပြီးနောက် ကျွန်ုပ်သည် သင့်ရုံးကို တက်ရောက်လေ့လာနိုင်ပါသလား။

ဟုတ်ပါတယ်၊ ကျွန်ုပ်တို့ရုံးကို တက်ရောက်လေ့လာရန် ကျွန်ုပ်တို့ကို ကြိုဆိုပါသည်။ ကျွန်ုပ်တို့အကြားတွင် အလိုက်အလာကို ရှာဖွေရန်အတွက် အခွင့်အလမ်းရှိပါသည်။

သင့်တို့၏ ထုတ်လုပ်ရေးအခြေစိုက်နေရာက ဘယ်မှာလဲ။

ကျွန်ုပ်တို့သည် တရုတ်နိုင်ငံ Jiangsu တွင် ထုတ်ကုန်များကို ထုတ်လုပ်ပြီး တောင်းပြထားသည့် ပণုံမှန်များနှင့် ပမာဏများအရ အလွယ်တကူ တရုတ်နိုင်ငံမှ သင့်နိုင်ငံသို့ ပို့ပေးပါမည်။

သင့်တို့သည် မြောက်များကို ပေးနိုင်ပါသလား။

ဟုတ်ပါတယ်၊ ကျွန်ုပ်တို့ပေးနိုင်ပါသည်။