ဖောက်သည်သည်သည် စွမ်းအင်သုံး ဘက်ထရီအသစ် ထုတ်လုပ်သူဖြစ်ပြီး အဓိကအားဖြင့် လီသီယမ် ဘက်ထရီ မော်ဂျူးများကို ထုတ်လုပ်သည်။ ဘက်ထရီမော်ဂျူးတွေကို ချိတ်ဆက်ဖို့ မြင့်မားတဲ့သန့်ရှင်းမှုရှိတဲ့ နီကယ်ကြိုးပမ်းပစ္စည်း လိုအပ်ခဲ့ပြီး အထူးလိုအပ်ချက်တွေထဲမှာ အောက်ပါတွေ ပါဝင်ပါတယ်။

ဖောက်သည်သည်သည် စွမ်းအင်သုံး ဘက်ထရီအသစ် ထုတ်လုပ်သူဖြစ်ပြီး အဓိကအားဖြင့် လီသီယမ် ဘက်ထရီ မော်ဂျူးများကို ထုတ်လုပ်သည်။ ဘက်ထရီမော်ဂျူးတွေကို ချိတ်ဆက်ဖို့ မြင့်မားတဲ့သန့်ရှင်းမှုရှိတဲ့ နီကယ်ကြိုးပမ်းပစ္စည်း လိုအပ်ခဲ့ပြီး အထူးလိုအပ်ချက်တွေထဲမှာ အောက်ပါတွေ ပါဝင်ပါတယ်။

မြင့်မားတဲ့ လျှပ်ကူးမှု ဘက်ထရီ ချိတ်ဆက်မှုရဲ့ လျှပ်ကူးမှုကို အာမခံဖို့၊ အတွင်းခံ ခုခံမှုကို လျှော့ချဖို့၊ ထိရောက်မှုကို တိုးမြှင့်ဖို့ပါ။

သံချေးတက်ခြင်း ခံနိုင်ရည်- အပူချိန်မြင့်ပြီး ရေရှည်သုံးတဲ့ ပတ်ဝန်းကျင်မှာ မျက်နှာပြင်မှာ oxidation သို့မဟုတ် အပျက်အစီးမရှိဘူး။

မြင့်မားတဲ့ ခိုင်မာမှုနဲ့ ပျော့ပြောင်းမှု ၎င်းဟာ စက်မှုဖိအားကို ခံနိုင်စွမ်းရှိပြီး ထုတ်လုပ်ရေးနဲ့ ရော်ထားရေး လွယ်ပါတယ်။

အသေးစိတ်အချက်အလက်များ တိကျသည် အနံ၊ ထူထပ်မှုနှင့် အခြားအတိုင်းအတာ တိကျမှု ထိန်းချုပ်မှု ± 0.01mm အတွင်းရှိသည်။

ကျွန်တော်တို့ရဲ့ ဖောက်သည်တွေရဲ့ လိုအပ်ချက်တွေကို လိုက်ပြီး အောက်ပါ ဖြေရှင်းနည်းတွေကို ပေးပါတယ်။

ပစ္စည်းရွေးချယ်မှု လျှပ်စစ်ကူးစက်မှုနှင့် အပျက်အစီး ခံနိုင်ရည်ကို သေချာစေရန် ၉၉.၆% ကျော်သော သန့်ရှင်းမှုရှိသော စက်မှုအဆင့် သန့်ရှင်းသော နီကယ်စတစ်စတစ်စတွေကို အကြံပြုသည်။

လုပ်ငန်းစဉ် Optimizatio: အအေးစက်လှည့်ခြင်းနှင့် တိကျသော အပူပေးခြင်းလုပ်ငန်းစဉ်များသည် မျက်နှာပြင်အဆုံးသတ်မှုရရှိစေရင်း ပစ္စည်း၏ ခိုင်မာမှုနှင့် ပျော့ပြောင်းမှုကို မြှင့်တင်ပေးသည်။

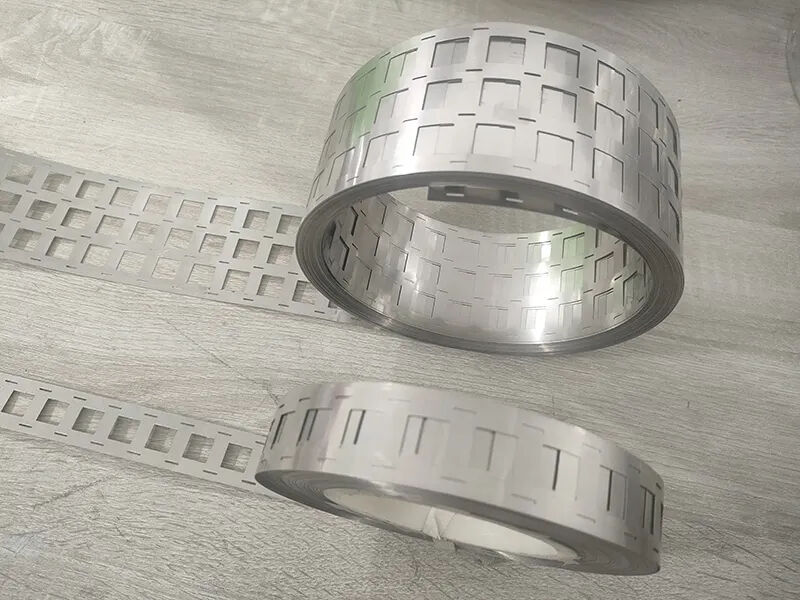

အလိုက်သင့် ထုတ်လုပ်မှု Customer requirements များအရ nikel tape များအတွက် အသေးစိတ်သတ်မှတ်ချက် အမျိုးမျိုး၊ အကျယ် ၁၀ မီလီမီတာ၊ ၁၅ မီလီမီတာ၊ အထူ 0.1 မီလီမီတာ၊ 0.2 မီလီမီတာ ပေးနိုင်ပါသည်။

စမ်းသပ်ခြင်းနှင့် အထောက်အထားပေးခြင်း ပစ္စည်းများသည် ဖောက်သည်၏ နည်းပညာဆိုင်ရာ လိုအပ်ချက်များကို ဖြည့်ဆည်းပေးရန် လျှပ်စစ်ကူးနိုင်မှု စမ်းသပ်မှု အစီရင်ခံစာများနှင့် အပျက်စီးမှု ဆားဖြန်းဆေး စမ်းသပ်မှု အစီရင်ခံစာများကို ပေးပို့ရမည်။

ပို့ဆောင်မှု: ပထမ အကြောင်းအရာ ၁၀၀ ကီလိုဂရัမ် သြင်းတန်း နီကဲလ် စားချို့များကို ၁၈ ရက်အကြာ အဆုံးချိန်ဖြင့် နှစ်မျိုးအရွယ်အစားဖြင့် ပေးပို့ပါမည်။

ဝန်ဆောင်မှုများ

Angganw: နီကဲလ် စားချို့တွင် ဆေးခတ်မှု အကျိုးသက်ရောက်မှုကို ပိုမိုကောင်းမွန်စေရန် သူငယ်ချင်းများ၏ ထုတ်လုပ်မှုကို တိုးတက်စေရန် အကြံပြုချက်များ ပေးပို့ပါ။

နီကဲလ် စားချို့နှင့် ဘက်တဲ့တွင် ဆေးခတ်မှုပြဿနာများကို ဖြေရှင်းရန် အင်တာန౮တွင် ဝန်ဆောင်မှု ပေးပို့ပါ။

ဘက်တဲ့မော်ဂျူးတွင် ထုတ်ကုန်၏ ကိုင်တွယ်သုံးစွဲမှုအကျိုးသက်ရောက်မှုကို သိရှိရန် မှန်ကန်သော ပြန်လည်ရောက်ရှိမှု ပြုလုပ်ပါ။

အမှတ်တမ်း: Pure နီကဲလ် (≥99.6%)

အလေးချိန်: 0.1mm / 0.2mm

အကျယ်: 10mm / 15mm

Resistivity: ≤9.8 μΩ·cm

Tensile strength: ≥400 MPa

ကြောင့်များအရ ထိန်းချုပ်မှု: မြင့်တက်သော လောင်းဖွံ့အချိန် (95%RH) တွင် ၁၀၀၀ နာရီအတွင်း ဆိုးမှုမရှိသည်

လုပ်ဆောင်မှုစူးစမ်းခြင်း: anggan က ပုံမှန် nickel ပုံစံသည် mass production တွင် ကောင်းမွန်စွာလုပ်ဆောင်ပြီး ဆောင်းပါးများစွာ လုပ်ငန်းတွင် welding efficiency နှင့် stability ကို တိုးတက်စေပြီး battery module ၏ အလုပ်လုပ်ဆောင်မှုကို အလွန်တိုးတက်စေသည်

qualité ကို မြှင့်တင်ခြင်း: dimension accuracy နှင့် surface finish သည် automation equipment တို့၏ လိုအပ်ချက်များကို ကိုက်ညီပြီး ထုတ်လုပ်ရေး loss rate ကို လျော့နည်းစေသည်