Monel K500 Thermal Spray Wire – Exceptional Strength and Wear Resistance for Extreme Conditions

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

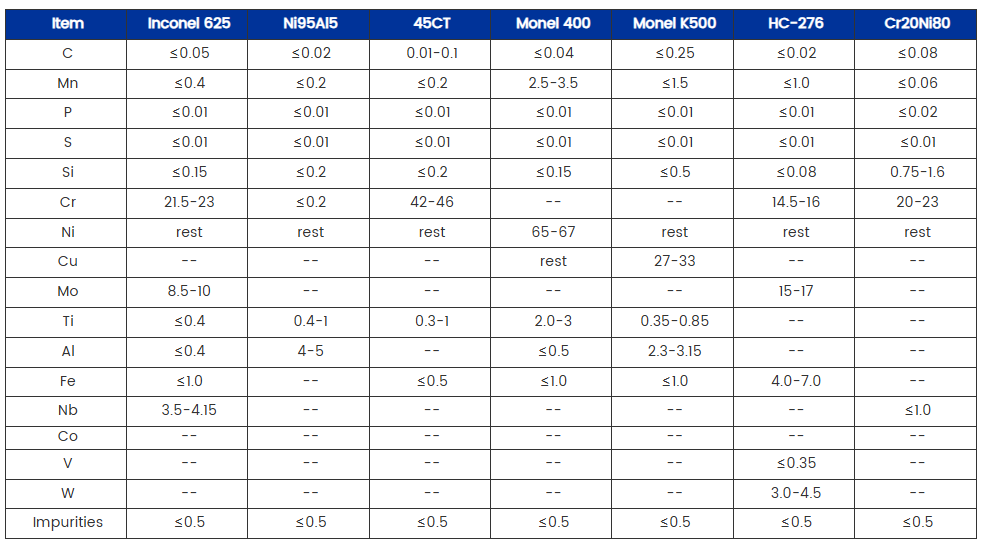

- Specification

- Off-the-shelf supply

- FAQs

- Recommended Products

-

High Strength and Hardness: Precipitation-hardened for increased mechanical durability.

-

Excellent Corrosion Resistance: Performs well in seawater, acidic, and alkaline environments.

-

Superior Wear and Erosion Resistance: Suitable for high-friction and high-impact applications.

-

Non-Magnetic: Maintains low magnetic permeability even in extreme conditions.

-

Thermal Stability: Retains performance at elevated temperatures.

-

Marine and Offshore Industry

-

Protects ship components, propeller shafts, and offshore structures from seawater corrosion.

-

Extends the service life of marine equipment exposed to harsh oceanic conditions.

-

-

Oil and Gas Industry

-

Used for coating valves, drilling tools, and production equipment to resist corrosion and wear.

-

Provides durability in sour gas and high-pressure environments.

-

-

Aerospace Industry

-

Applied to turbine blades, landing gear, and structural components requiring high strength and corrosion resistance.

-

Enhances performance under extreme mechanical and thermal stresses.

-

-

Chemical Processing

-

Coats processing equipment, reactors, and pumps handling aggressive chemicals.

-

Prevents degradation from acidic and caustic substances.

-

-

Power Generation

-

Used in thermal and nuclear power plants to protect steam turbine components and heat exchangers.

-

Ensures long-term performance in high-temperature environments.

-

-

Extending Equipment Lifespan: Reducing wear, oxidation, and maintenance costs.

-

Enhancing Operational Efficiency: Providing reliable performance in demanding environments.

-

Improving Safety and Performance: Offering superior corrosion and wear resistance for critical applications.

Monel K500 is a nickel-copper alloy that offers superior corrosion resistance, high strength, and excellent wear resistance. With the addition of aluminum and titanium, Monel K500 is precipitation-hardened to provide enhanced mechanical properties compared to Monel 400. This makes it an ideal choice for thermal spray coatings in extreme environments where both corrosion and wear resistance are crucial.

Key Properties of Monel K500 Spray Wire

Applications of Monel K500 Thermal Spray Wire

Meeting User Needs with Monel K500 Spray Wire

Industries operating in extreme conditions require materials that offer both durability and reliability. Monel K500 thermal spray wire meets these needs by:

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.