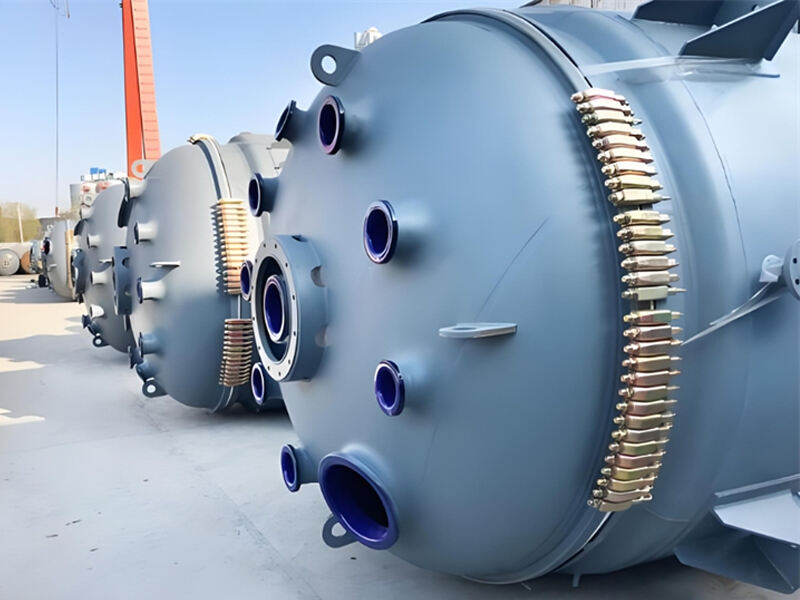

Эрсдэлтэй хамгаалалт:

Цэрэг элементээс үүсэх оксид хамгаалалтын дэлгэцийн ур чадвар нь хавтгай төмсийг аль ч орчинд эрсдэлтэй болгоно.

Тохимор бусад хангалттай хүчирхэг ба эрс:

Ялгаатай төрлийн хавтгай төмс нь их сангийн завсартай хугацаанд нөхцөл бүрийн дагуу сайн механик үйлдлүүдийг хадгалах боломжтой.

Сайн ажиллах боломж, холболтын чадвар:

Хүчирхэг, хурдан, холболтын үйл ажиллагааг хялбархан ажиллуулж, бүтээгдэхүүний зураасан хэлбэрийг үйлдвэрлэхэд зориулсан.

Зүрхэн зүрхэн байдлын хариуцлагатай:

Шилжүүлэх, цонхны үзэг, гэх мэт процесстэй хамт аль ч бүтээгдэхүүний зүрхэн зүрхэн байдлыг нэмэгдүүлэх боломжтой.

Эрүүл мэнд болон хамгаалал:

Амьсгалтай биш, зохицуулахад хялбар, эсэхээр хамгийн ихэнхээс нь эд хориг, эмчилгээний өргөтгөлийн талбайд ашиглагдах боломжтой.

Урт үеийн ажиллах хугацаатай, засварын үнэ цэнэтэй ** :

Үргэлжлэх чадварын дагуу халуунд тулсан байдалд унасан байхгүй бөгөөд урт үеийн ашиглахад засварын шаардлага багасгана.