Premium ERNiCrMo-4 (C-276) varžymo drąsiai – didelė sandėlio talpa, gamintojo kaina

Daugiau: ERNiCrMo-3,ERNiCrMo-4,ERNiCrMo-13,ERNiCrFe-3,ERNiCrFe-7,ERNiCr-3,ERNiCr-7,ERNiCu-7,ERNi-1, ER70S-6

- Apžvalga

- Rekomenduojami produktai

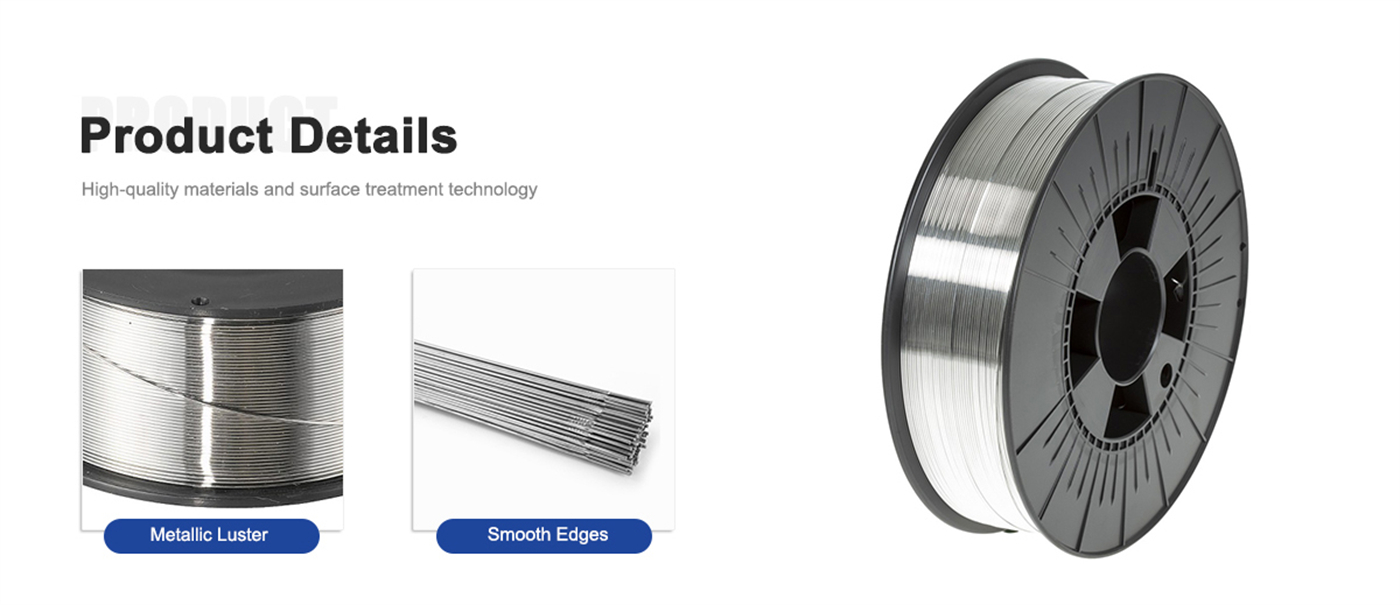

Apie ERNiCrMo-4 (C-276) Svaidymo Marškinius

ERNiCrMo-4 (C-276) suvirkimo drutas yra aukštos našumo nikeliu pagrįstas aliejus, skirtas nikelinei, crominiams ir molibdano medžiagoms suvirkimui ekstremaliose aplinkose. Jis plačiai naudojamas chemijos apdorojimo, energijos gamybos, naftos ir dujų, jūrų ir oro erdvės pramonėse dėl jo puikių korozijos varžymo savybių, aukštos stiprumo ir puikios suvirkimo gebėjimo.

Pagal mūsų tiesiogines iš gamyklos kainas, siūlome aukštos kokybės ERNiCrMo-4 suvirkimo dratus su dideliu sandėlio likutimi, užtikrinant nuolatinę tiekimą pramonei visame pasaulyje. Arba jei jums reikia mažų ar masinio užsakymo, mes siūlome greitą vežimą ir individualias pakuotės galimybes, atitinkančias jūsų specifinius poreikius.

Medžiagos apžvalga: ERNiCrMo-4 (C-276) varno druto savybės

ERNiCrMo-4 (C-276), kuris taip pat žinomas kaip Hastelloy® C-276, yra paminėtas dėl savo neįprastų savybių:

✔ Puikus korozijos pasipriešinimas – Saugo nuo pūtų, tarpdangčiųjų korozijos ir streso korozijos spragos agresyviuose, aukštos rūgšties ir chloridų turtinguose aplinkose.

✔ Aukštų temperatūrų stabilumas – Išlaiko ekstremalią šilumą iki 1093°C (2000°F) be medžiagos degeneracijos.

✔ Puikus suvilkimojoji savybė – Gaminamas garsi, defektų nesutrikdantis suvilkimas su minimaliu spragų ar poroziteti.

✔ Pasipriešinimas sulfidų ir chloridų streso spragoms – Idealus sunkiomis pramoninėmis sąlygomis chemijos gamyklose ir jūros platformose.

✔ Geresnės mechaninės savybės – Užtikrina aukštą išsigyvenamumą ekstremaliose slėgio sąlygomis.

Šios savybės daro ERNiCrMo-4 suvilkimo juostą būtina pramonei, reikalaujančiai ilgalaikių, korozijai pasipriešinančių suvilkimų.

Pramonės standartai ir specifikacijos

Mūsų ERNiCrMo-4 (C-276) suvilkimo juosta atitinka tarptautinius kokybės standartus, užtikrinančius aukštą patikimumą ir suderinamumą su kritiniais suvilkimo aplikacijomis.

Norminė specifikacija

AWS A5.14 ERNiCrMo-4

UNS numeris N10276

ASTM standartas ASTM B574, ASTM B575

ISO standartas ISO 18274: NiCr15Mo16Fe6W4

Tai užtikrina, kad mūsų suvienodinimo dratus atitinka griežčiausius pramonės reikalavimus saugumo, išlikosios galios ir našumui.

ERNiCrMo-4 (C-276) suvienavimo druto taikymai

1. Chemijos gamybos pramonė

Rūgštinių saugyklių ir potvynių – Saugo nuo korozijos chemikalijų, įskaitant chloridinę ir sieros rūgščių.

Šilumos mainytojai ir reaktoriai – Užtikrina išlikosios galios aukštos temperatūros ir aukštos slėgio aplinkoje.

Cheminio mišymo įrenginiai – Blokuoja taršą ir korozijos nesėkmes.

2. Elektrinės energijos gamyba ir branduolinė pramonė

Branduolinio reaktoriaus komponentai – Atsparūs spinduliavimui ir ekstremaliam šiluminei.

Svairo ir dujų turbinės – Teikia oksidacijos atsparumą aukštos temperatūros sąlygomis.

Kuro trubos ir šilumos atkurimo sistemos – Išlaiko termalinį ciklą ir koroziją.

3. Naftos ir dujų perdirbamosios įmonės

Potvyniai ir jūrų įrangos įrenginiai – Pasipriešina sulfido stresiniam spragstam (SSC) ir vandenilio krūvėjimui.

Nešios procesavimo vienetai – Išlaiko aukštais riebalais ir rūgščiuose aplinkose.

LNG objektai ir kriogeninės programos – Palaiko konstrukcinę tvirtovę žemų temperatūrų sąlygomis.

4. Oro ir jūrų inžinerija

Komponentai reaktorių varikliams – Idealu aukštos temperatūros ir aukštos slėgio taikymams.

Laivo statyba ir subžalinis įranga – Užtikrina korozijos priešinimą druskos vandens aplinkoje.

5. Maisto ir vaistų pramonė

Higieninis suvilkimas maisto gamybos įrenginiams – Užtikrina higieną ir kontaminacijos nepriklausomumą.

Medicinos prietaisų gamyba – Teikia biokompatibilumą ir steriliavimo išteklių priešinimą.

Kodėl pasirinkti mūsų ERNiCrMo-4 (C-276) suveldymo gyselę?

Gamintojo tiesioginė kainų politika – Konkurencingos partijos prekių kainos dideliems užsakymams ir OEM klientams.

Aukšta sandėlio talpa – Paruošta siųsti inventorių skubiems pramoniniams projektams.

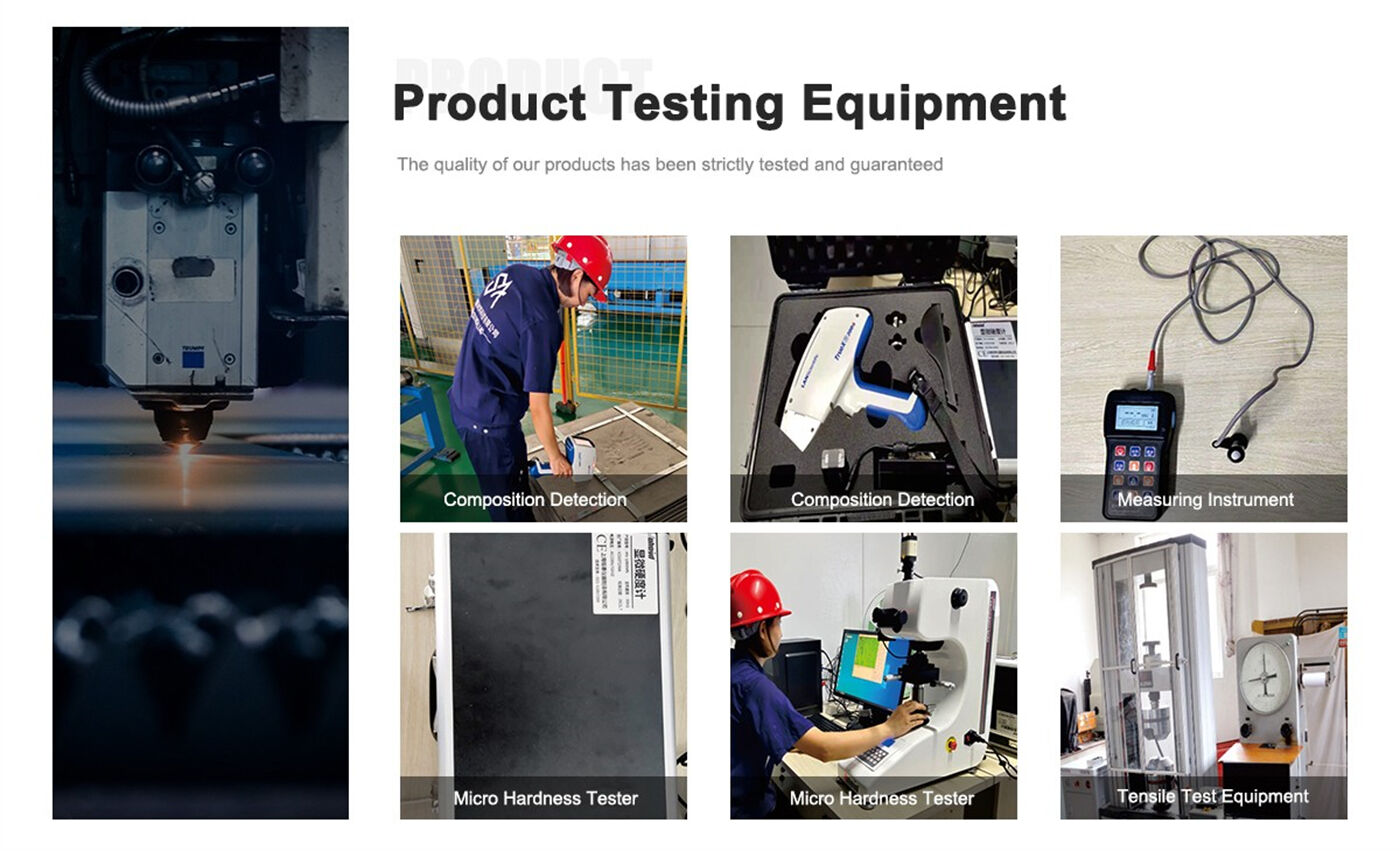

Sertifikuota geros kokybės – Atitinka AWS, ASTM ir ISO pramonės standartus.

Individualūs dydžiai ir pakavimas – prieinami katros, šluosčių ir iškirptų į ilgį variantuose.

Greitas ir patikimas pasaulinis pristatymas – Greitas siuntimas klientams visame pasaulyje.

Patikima tiekimo grandinė – Užtikrinama nuolatinė sandėlio talpa pramonės taikymams.

Užsakykite pramoginę ERNiCrMo-4 (C-276) suvienodinimo gija šiandien – Geriausios gamintojo kainos!

Ieškote aukštos kokybės suvienodinimo gijos su garantuotu sandėlio likučiu? Susisiekite su mumis šiandien dėl partijos kainų, specialių nuolaidų ir greito pristatymo.

| Prekė | ERNiCrMo-3 | ERNiCrMo-4 | ERNiCrMo-13 | ERNiCrFe-7 | ERNiCr-3 | ERNiCu-7 | ERCuNi | ERNi-1 |

| C | 0.1 | 0.02 | 0.01 | 0.04 | 0.1 | 0.15 | 0.03 | 0.15 |

| M | 0.05 | 1 | 0.5 | 1 | 2,5-3,5 | 4 | 0.5-1.0 | 1 |

| Fe | 5 | 4-7 | 1.5 | 7-11 | 3 | 2.5 | 0.65 | 1 |

| P | 0.02 | 0.04 | 0.015 | 0.02 | 0.03 | 0.02 | 0.01 | 0.03 |

| S | 0.015 | 0.03 | 0.005 | 0.015 | 0.015 | 0.015 | 0.01 | 0.015 |

| Taip. | 0.05 | 0.08 | 0.1 | 0.5 | 0.5 | 1.25 | 0.15 | 0.75 |

| Cu | 0.5 | 0.5 | N/a | 0.3 | 0.5 | atsisukimas | atsisukimas | 0.25 |

| Ni | ≥58 | atsisukimas | atsisukimas | atsisukimas | ≥67 | 62-69 | 30-32 | ≥93 |

| Co | N/a | 2.5 | 0.3 | N/a | N/a | N/a | N/a | N/a |

| Asis | 0.4 | N/a | 0.1-0.4 | 1.1 | N/a | 1.25 | 0.15 | 1.5 |

| Ti | 0.4 | N/a | N/a | 1 | 0.75 | 1.5-3 | 0.5 | 2-3.5 |

| Kr | 20-23 | 14.5-16.5 | 22-24 | 28.5-31 | 18.0-22.0 | N/a | N/a | N/a |

| Nb+Ta | 3.5-4.15 | N/a | 1.8-2.5 | 0.01 | 2.0-3.0 | N/a | N/a | N/a |

| Mo | 8.0-10 | 15-17 | 15-16 | 0.5 | N/a | N/a | N/a | N/a |

| V | N/a | 0.35 | N/a | N/a | N/a | N/a | N/a | N/a |

| W | N/a | 3,0-4,5 | N/a | N/a | N/a | N/a | N/a | N/a |

| Atsisukimas | ≤0,50 | ≤0,50 | ≤0,50 | ≤0,50 | ≤0,50 | ≤0,50 | ≤0,50 | ≤0,50 |

| Variklio drąsos ir variklio drąsos lyginis kabliukas | |

| Produkto modelis (AWS) | PROGRAMA |

| ERNiCr-3 | Sviedinimo 600, 601 ir 800 ligatų patalpinimui, skirtingų metalų sviedinimui tarp nerūdijančiojo plieno ir anglies plieno ERNiCrFe-7; Inconel ligatų sviedinimui pagal ASTM B163, 166, 167 ir 168 |

| ERNiCrFe-6 | Plieninių ir Inconel konstrukcijų sviedinimui, plieno ir nerūdijančiojo plieno bei nikelinei bazių ligatų sviedinimui |

| ERNiCrCoMo-1 | Skirtingų metalų jungimui, nikelio-chromilio-kobalto-ligatinėse ir įvairiose superligatuose |

| ERNiCrMo-3 | Jis naudojamas nickelio aliejų, anglies plieno, nerūdijančio plieno ir žemiųjų aliejų plieno sujungimui, pagrindinė paskirtis – 625, 601, 802 aliejų ir 9% nickelio aliejų sujungimui. |

| ERNi-CI | Pramoninis garsusis nickelis naudojamas marcinių ir pilkųjų deformacinių plieno rūtulių sujungimui. |

| ERCuNi | Naudojamas 70/30, 80/20, 90/10 varni-nickelio aliejų sujungimui. |

| ERNiCu-7 | Naudojamas nickelio-varnio aliejų B127, 163, 164 ir 165 ir kt. sujungimui. |

| ERNi-1 | Naudojamas garsųjų nickelio gaminių ir leistinių sujungimui, pvz., ASTM B160, 161, 162, 163 nustatytose aliejyse. |

| ERNiFeMn-CI | Naudojamas sferoidalios angies rūtulio plieno, trilobinio plieno, deformacinių rūtulio plieno ir pilkojo plieno sujungimui tarpusavyje arba su nerūdijančiu plieno, anglies plieno, žemės aliejų plienu ir kitais nickelio aliejiais. |

| ERNiCrMo-4 | Naudojamas nickelio-chromolio-molibdeno aliejų sujungimui tarpusavyje arba nickelio-chromolio-molibdeno aliejų ir plieno bei daugeliu kitų nickelio bazės aliejų sujungimui. |

| ERNiCrMo-11 | Jis naudojamas nickel-chromium-molybdeno aliaus savo varžymui, arba nickel-chromium-molybdeno aliaus ir plieno varžymui bei daugeliui kitų nickel-bazės aliejų, be to, gali būti naudojamas kaip viršutinis varžymas nickel-chromium-molybdeno aliaus ir plieno varžos jūros |

| ERNiCrMo-13 | Naudojama žemesniu anglies kiekio nickel-chrom-molibdeno aliejų varžimui |