Hastelloy C-22 rytai – Aukšta trukoja kausiam ir oksiduojantiems aplinkai

Siūlome tiesioginę gamyklą kainuojančias kainas ir specialius nuolaidas už masinį užsakymus. Arba jums reikia mažų ar didelių kiekių, mūsų produktai siunčiami greitai, kad būtų užtikrintas patikimas tiekimas pramonei visame pasaulyje.

- Apžvalga

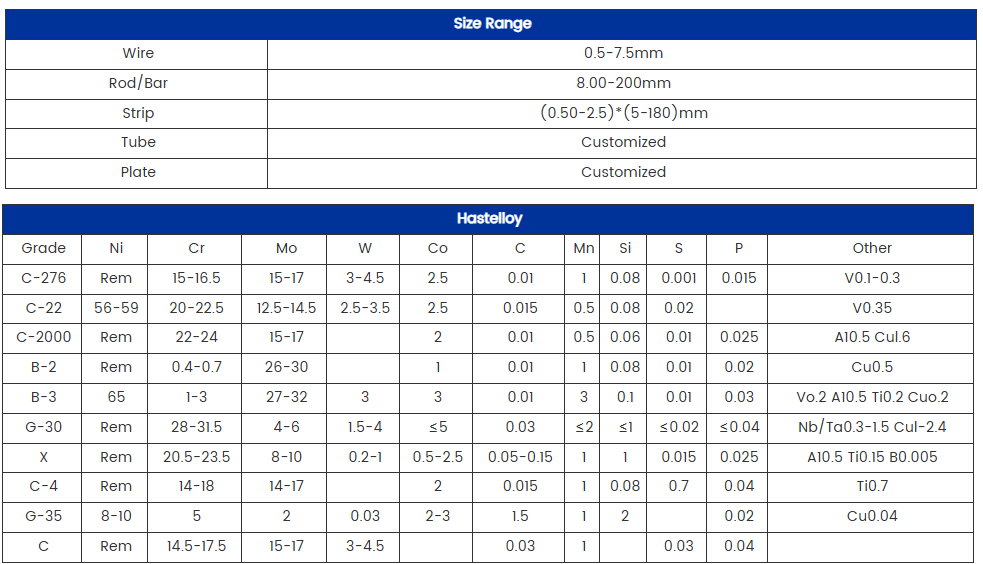

- Specifikacija

- Paraiškos

- Dažniausiai užduodami klausimai

- Rekomenduojami produktai

-

Nikolas (Ni): Balansas

-

Chromas (Cr): 20,0-22,5%

-

Molibendas (Mo): 12,5-14,5%

-

Geležis (Fe): 2,0-6,0%

-

Kobaltas (Co): ≤ 2,5%

-

Volframasis (W): 2,5-3,5%

-

Manganas (Mn): ≤ 0,5%

-

Silicis (Si): ≤ 0,08%

-

Anglis (C): ≤ 0,01%

-

Sulfuras (S): ≤ 0,02%

-

Cheminė apdorojimo pramonė: Naudojama vamzdynų sistemose, šilumos mainykuose ir reaktoriuose, kurie dirba su stiprybiomis rūgštimis, tokios kaip svarčioji, chloridinė ir nitro rūgštys.

-

Vaistų ir maisto gamyba: Įsitikina, kad yra higieniškas ir kontaminacijos nemokamas skysčių perdavimas griežtose apdorojimo sąlygose.

-

Elektrinės: Taikoma dūmų dujų desulfurizacijos sistemose ir šalytinėje grandinėje, kad galėtų išlaikyti koroziją keliančias dūmų dujas.

-

Jūrų ir kontinentinis pramonė: Siūlo puikią jūros vandens korozijos atsparumą, dėl ko ji yra idealiai tinkama destiliavimo jūrų stotims ir jūriniams konstrukciniams elementams.

-

Gamtinės dujos ir kosmoso pramonė: Naudojama kuro ir hidraulinio sistemos, pateiktos ekstremaliam temperatūrų intervalui ir agresyviems cheminiams aplinkai.

-

Be suvienodžių rypuoliai: Gaminti be suvaržymo, užtikrinant geresnę stiprumo ir slėgio varžymo savybes.

-

Su suvienodžiais rypuoliai: Ekonomiškesnis variantas, tinkamas taikymams, kur nepriklauso nuo absoliučios struktūros integriteto.

-

Sutrikdymo skilties rūrybai: Sukurta naudojimui agresyviuose aplinkose, kad būtų užtikrintas efektyvus šilumos perdavimas.

-

Instrumentinės rūrybos: Naudojama aukštos tikslumo programose, kur reikalingas nešluostis veikimo rodiklis.

-

Kietosios medžiagos pasirinkimas: Naudojamas aukštos kokybės nikelio aljusas, kad būtų užtikrintos optimalios cheminės savybės.

-

Rypuolio formavimas: Rypuoliai ištraukiami arba sukasi į be suvienodžių ar su suvienodžiais formoms.

-

Šiluminė apdorojimo: Sprendinio atkarpa padidina korozijos išnykimo ir mechaninės stiprumo.

-

Virimo apdorojimas: Taikomas oksidacijos šalinimas ir pasivavimas, siekiant pagerinti švarumą ir ilgalaikią naudojamumą.

-

Kokybės tikrinimas: Įskleidžia hidrostatinį, elektrodinaminį ir ultragarsrinį testavimą, atitinkant ASTM B622 ir ASTM B619 standartus.

-

Papildomos galimybės: Galimi skirtingi dydžiai, sienos storis ir ilgiai.

-

Kainų efektyvumas: Masinė gamyba ir tiesioginis tiekimas iš gamybos įmonės užtikrina konkurencingas kainas.

-

Pasaulinis tiekimai: Patikimos tiekimo grandinės užtikrina greitą ir saugų pasaulio mastu priežiūrą.

-

Suderinimas su tarptautiniais standartais: užtikrina saugumą, veikimą ir ilgalaikumą pramoniniuose taikymuose.

Hastelloy C-22 rūtai yra plačiai pripažįstami dėl jų puikios korozijos varžymo savybių agresyviosiose aplinkose, įskaitant rūgštines ir oksiduojančias sąlygas. Jie gaminiama naudojant nikeli-chrom-molibdano lyginį, teikiant ypatingą mechaninę stiprumą ir ilgalaikią veikimą, todėl jie yra puikus pasirinkimas pramone, tokiose kaip chemijos apdorojimo, energijos gamyba ir jūrų technologijos.

Medžiagos apžvalga

Hastelloy C-22 (UNS N06022) yra daugialypus ir korozijos varžantis lyginis, kurio pagrindinis sudedamasis dalis yra nikelis, chromas, molibdanas ir geležis. Ši unikali sudėtis suteikia puikią varžymo prieš šluostus, tarpkampių koroziją ir streso korozijos spragos įvairose ekstremaliose aplinkose.

Chiminis sudėtis:

Hastelloy C-22 Rūtų Taikymai

Hastelloy C-22 rūstai plačiai naudojami įvairiose pramonės šakose dėl jų išskirtinio atsparumo abiems rūgštams ir oksiduojantiems agentams. Kai kurie pagrindiniai panaudojimai apima:

Hastelloy C-22 rūstų tipai

Hastelloy C-22 rūstai prieinami įvairiais tipais, kad atitiktų skirtingus pramonės poreikius:

Gamybos procesas

Hastelloy C-22 rūstų gamyba yra susijusi su griežtomis kokybės kontrolės procedūromis, kad būtų užtikrintas aukštas išlyginimo ir korozijos varžymo lygis:

Vartotojų paklausa ir rinkos tendencijos

Didejant pramonės paklausai po korozijos varžymo medžiagoms, Hastelloy C-22 ruošikliai taps esminiu elementu įvairiose srityse. Pagrindiniai pokytys apima:

DAK:

Kiek laiko užtruks pristatymas?

Tai priklauso nuo užsakymo kiekio, mažiems užsakymams 10-30 dienas. Dideliems užsakymams reikia 60 dienų.

Ar priimame OEM/ODM gamybos užsakymus?

Taip! Priimame OEM/ODM gamybos užsakymus. Galite mums nusiųsti savo pavyzdžius arba brėžinius.

Kaip valdyti produkto kokybę? Ar produktų cheminiai savybės atitinka kokybės standartus?

Su profesionaliu kokybės komandu, moderniu produkto kokybės planavimu, griežtu įgyvendinimu ir nuolatiniu patobulinimu išdavome produkto kokybės inspekcinį certifikatą, įskaitant cheminių analizės ataskaitas.

Ar jūsų įmonė gali pateikti detalizuotus techninius duomenis ir brėžinius?

Taip, galite. Prašome pranešti mums apie reikalingus produktus ir jų taikymą, ir mes jums nusiųsiame detalizuotus techninius duomenis ir brėžinius vertinimui ir patvirtinimui.

Kaip tvarkote priespardes ir po pardavimo paslaugas?

Mes turime profesionalų verslo komandą, kurios nariai dirbs vienas prie vieno, saugodami jūsų produktų poreikius, o jei užsiskundsite, jis galės atsakyti į jūsų klausimus!

Ar galiu apsilankyti jūsų gamykloje prieš užsakymo pateikimą?

Taip, jūs esate sveikiname apsilankyti mūsų gamyklą. Malonu turėti galimybę pažinti vienas kitą.

Kur yra jūsų gamybos bazė?

Mes gaminame produktus Jiangsu, Kinijoje ir siunčiame juos iš Kinijos į jūsų šalį kaip galima greičiau, kas paprastai priklauso nuo jūsų produkto reikalavimų ir kiekio.

Ar galite nusiųsti пробas?

Taip, galime.