Long-Lasting FeCrAl Alloy Resistance Wires: 0Cr21Al6 and 0Cr23Al5 for High-Temperature Environments

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

-

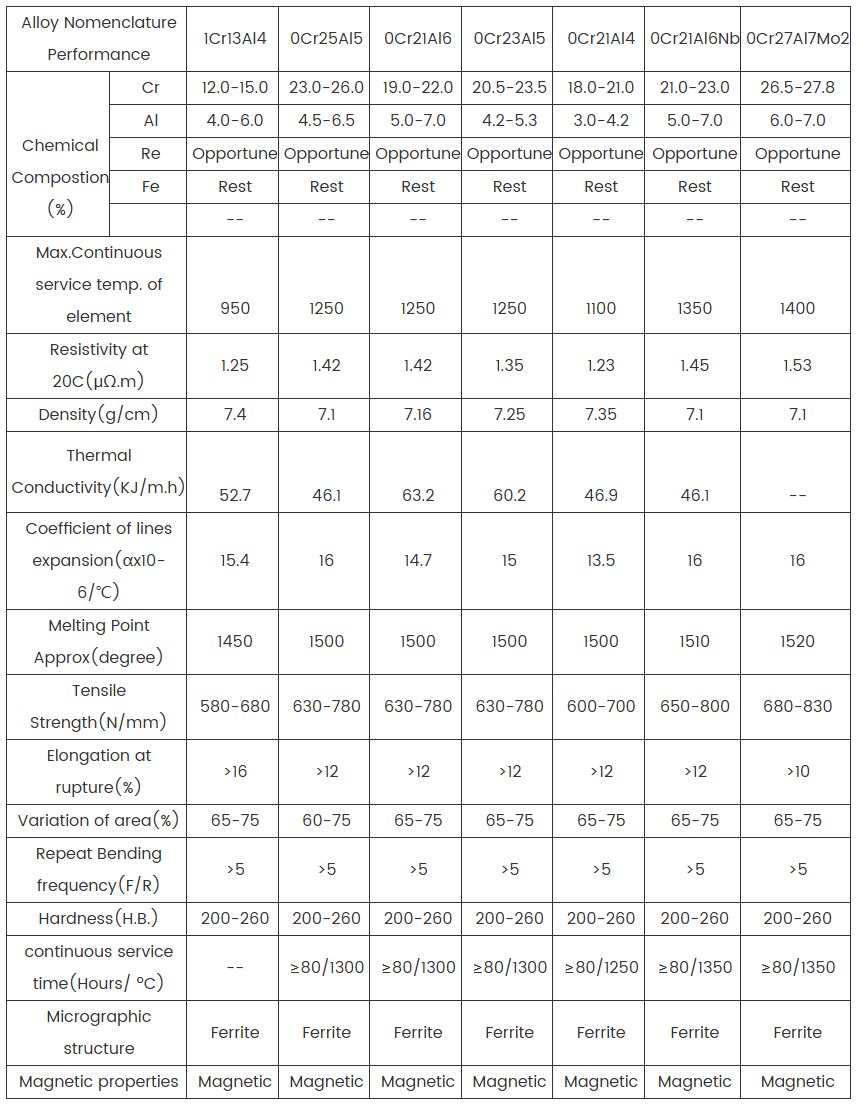

0Cr21Al6: This alloy contains 21% chromium and 6% aluminum. Its composition provides excellent oxidation resistance and high-temperature strength, making it suitable for a variety of industrial applications. 0Cr21Al6 can withstand temperatures up to 1200°C, making it ideal for environments where heating elements are exposed to continuous heat for extended periods.

-

0Cr23Al5: With 23% chromium and 5% aluminum, 0Cr23Al5 offers enhanced oxidation resistance and higher thermal stability than 0Cr21Al6. It is capable of withstanding even higher temperatures, up to 1300°C, and is used in applications that demand maximum performance in extreme heat conditions.

-

Industrial Heating Elements

FeCrAl alloys are used extensively in industrial heating systems, including furnaces, kilns, and ovens. These heating elements operate at high temperatures for prolonged periods, and the ability of 0Cr21Al6 and 0Cr23Al5 alloys to resist oxidation and maintain stability under heat makes them ideal for such demanding applications. Their durability ensures that heating elements continue to perform effectively, reducing the need for frequent replacements. -

Electric Heaters

Both alloys are also used in electric heating elements, such as space heaters, water heaters, and industrial dryers. In these systems, the alloys' ability to withstand continuous exposure to high temperatures and maintain consistent heat output is essential for ensuring long-term reliability and energy efficiency. The long lifespan of the heating elements helps reduce operational costs by minimizing maintenance and replacement needs. -

Heat Treatment Furnaces

0Cr21Al6 and 0Cr23Al5 alloys are also essential in heat treatment furnaces used in industries such as automotive manufacturing and aerospace. These furnaces require heating elements that can provide precise, stable heat over long periods for processes like tempering, annealing, and quenching. The alloys' high-temperature resistance and mechanical strength ensure reliable operation in these critical applications. -

Power Generation

In power generation, high-performance alloys are needed for components such as steam generators, heat exchangers, and exhaust systems. 0Cr23Al5, in particular, is highly sought after in power plants due to its higher temperature resistance. The alloy can withstand the extreme conditions found in these environments, providing consistent performance and durability in power generation systems. -

Laboratory Equipment

In laboratory and scientific applications, heating elements made from FeCrAl alloys are used in devices like sterilizers, furnaces, and drying equipment. These alloys are essential for laboratory environments where precise, consistent heating is required, and they maintain their performance over long periods of continuous use at high temperatures. -

High-Temperature Resistance

Both 0Cr21Al6 and 0Cr23Al5 alloys provide exceptional resistance to heat. The former is designed to perform well up to 1200°C, while the latter can handle even more extreme conditions, with a temperature range up to 1300°C. These high-temperature limits ensure that the alloys can be used reliably in various industrial heating applications. -

Oxidation Resistance

One of the most important characteristics of FeCrAl alloys is their ability to resist oxidation. 0Cr21Al6 and 0Cr23Al5 alloys are specifically formulated to prevent the formation of harmful oxide scales, which can degrade the performance of heating elements. This property is particularly important in environments like furnaces and kilns, where oxidation can significantly reduce the lifespan of heating elements. -

Mechanical Strength

In addition to their heat and oxidation resistance, 0Cr21Al6 and 0Cr23Al5 alloys maintain excellent mechanical strength under high temperatures. This strength ensures that heating elements do not deform or lose structural integrity when exposed to thermal stress, extending the overall lifespan of the components. -

Energy Efficiency

The electrical resistance of FeCrAl alloys is optimized to provide efficient heat generation. This means that heating systems can generate and maintain the necessary heat without consuming excessive energy, helping industries reduce operational costs and improve energy efficiency. -

Long Lifespan and Durability

The durability of 0Cr21Al6 and 0Cr23Al5 alloys is one of their most important features. These alloys can withstand prolonged exposure to high temperatures and thermal cycling, ensuring that heating elements last for long periods with minimal degradation. This durability reduces maintenance costs and the need for frequent replacements, providing industries with cost-effective, long-lasting solutions.

In industries where high temperatures are a regular part of operations, choosing the right resistance wire is essential for ensuring efficiency, longevity, and safety. FeCrAl alloys, specifically 0Cr21Al6 and 0Cr23Al5, have proven to be the optimal materials for high-temperature environments. These alloys offer outstanding performance, combining high oxidation resistance, excellent mechanical strength, and reliability in extreme conditions. This article will explore the features of these alloys, their diverse applications, and how they meet the increasing demands for durability and performance in industrial heating systems.

Material Introduction

FeCrAl alloys are composed of a blend of iron, chromium, and aluminum. These key elements give the alloys superior heat resistance and oxidation resistance, both of which are crucial in high-temperature applications. Chromium improves the alloy's ability to resist oxidation, while aluminum enhances its mechanical properties and stability at elevated temperatures. The alloys are known for their ability to maintain consistent electrical resistance, even in extreme conditions, making them ideal for use in heating elements.

Applications

FeCrAl alloys, particularly 0Cr21Al6 and 0Cr23Al5, are widely used across industries that rely on high-temperature environments for their operations. These alloys are crucial for applications that require efficient heating elements that can last for extended periods without degradation.

Meeting User Demands

Industries that rely on high-temperature heating systems have specific needs when it comes to materials. 0Cr21Al6 and 0Cr23Al5 alloys are designed to meet these needs, offering several key benefits for users in high-temperature environments.

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.