ຜູ້ສະໜອງຫຼັກຂອງ ERNiCrMo-4 (C-276) Welding Wire – ລາຄາດີທີ່ສຸດໃນອິນເຕີເນັດ

Thêm: ERNiCrMo-3,ERNiCrMo-4,ERNiCrMo-13,ERNiCrFe-3,ERNiCrFe-7,ERNiCr-3,ERNiCr-7,ERNiCu-7,ERNi-1, ER70S-6.

ພວກເຮົາສະຫນັບຄ່າຈັບມືຈາກໂຮງໝໍກັບສ່ວນຫຼຸດພິเศດສຳລັບການສັ່ງຊື້ຫຼາຍ. ບໍ່ວ່າທ່ານຕ້ອງການຈຳນວນນ້ອຍຫຼືຫຼາຍ, ອີຣິນຄຣມໂ-4 ຂອງພວກເຮົາ ໄດ້ຖືກສົ່ງອອກທົ່ວໄປ, ເປັນການສົ່ງອອກທີ່ສາມາດສົ່ງໄດ້ທົ່ວໂລກ.

- ຄວາມເປັນມາ

- ການໃຊ້

- FAQs

- ສິນຄ້າທີ່ແຈ້ງໄວ້

ເສັ້ນແຍມ ERNiCrMo-4 (C-276) ແມ່ນອັลໂລຍ໌ຕຳແໜ່ງ_nickel ທີ່ຖືກອອກແບບພິເສດສຳລັບການແຍມ Hastelloy C-276 ແລະອັลໂລຍ໌ອື່ນໆທີ່ມີຄວາມຕ້ອງການຕ້ອງກັບການເຄື່ອນໄຫວ. ເສັ້ນແຍມນີ້ຖືກໃຊ້ຢ່າງຫຼາຍໃນອຸດົມສາຫະກິດການປະมวลຜົນເຄມີ, ອຸດົມສາຫະກິດນ้ำມັນ & ຕັງ, ນັກຮຽນ, ມະຫາສະໝຸດ, ແລະ ອຸດົມສາຫະກິດບິນ ໂດຍຄວາມສາມາດໃນການຕ້ອງການຕ້ອງກັບການເຄື່ອນໄຫວ, ຄວາມແຂງແຮງທີ່ອຸນຫະພູມສູງ, ແລະ ຄວາມສາມາດໃນການແຍມທີ່ດີ.

ເປັນຜູ້ສະໜອງຫຼັກ, ພວກເຮົາສະໜອງເສັ້ນແຍມ ERNiCrMo-4 ໃນລາຄາອອນໄລນ์ທີ່ດີທີ່ສຸດ, ສົນຄ້າຈາກ;br;(factory-direct), ຢຶນຢູນການສົ່ງສິນຄ້າຄົບຖ້ວນ, ດິສີ້ນຄ້າຫຼາຍ, ແລະ ການສົ່ງອອກສຳລັບການສົ່ງສິນຄ້າສັນຍາ. ບໍ່ວ່າເປັນການແຍມສຳລັບອຸດົມສາຫະກິດຫຼັກຫຼາຍຫຼືການແຍມທົ່ວໄປ, ສິນຄ້າແຍມຄົນຂອງພວກເຮົາສົ່ງຜົນການລົງທຶນທີ່ດີແລະຄວາມແຂງແຮງ.

ຄວາມເປັນມາ: ອຸປະກອນຂອງ ERNiCrMo-4 (C-276) ເສັ້ນແຍມ

ERNiCrMo-4 ແມ່ນອັລຫຼາຍ_nickel-chromium-molybdenum ທີ່ມີການເພີ່ມເຂົາໄປຂອງ iron ແລະ tungsten, ເຮັດໃຫ້ມันເປັນໜຶ່ງໃນວัດຖຸສ່ວນປະສົມແລະຕ້ອງການການເຄື່ອນໄຫວທີ່ດີທີ່ສຸດ. มັນຖືກອອກແບບມາເພື່ອຕ້ອງການສິ່ງແວດລ້ອມເຄື່ອນໄຫວທີ່ຮ້າຍແຮງ, ຄວາມຮ້ອນສູງ, ແລະສະຖານະ oxidation, ເຮັດໃຫ້ມันເປັນຜູ້ເລືອກທີ່ຊິ່ງສຳຄັນສຳລັບການປະສົມປະສານທີ່ຮ້າຍແຮງ.

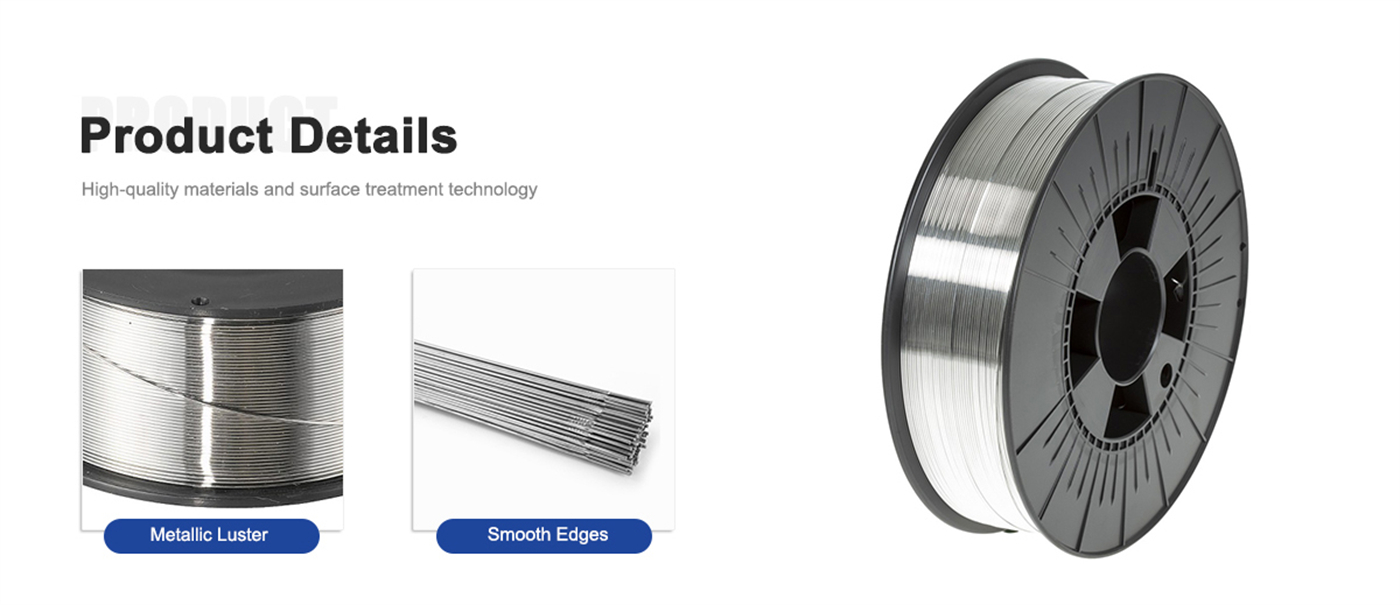

ຄุณสมบัติหลักของ ERNiCrMo-4 (C-276) ແຜນສົ່ງ

ຄວາມຕ້ອງການການເຄື່ອນໄຫວທີ່ດີທີ່ສຸດ - ຕ້ອງການສິ່ງແວດລ້ອມທີ່ເປັນกรົດ, oxidation, ແລະ chloride-rich, ເຮັດໃຫ້ມันສົມບູรณະສຳລັບການເຄື່ອນໄຫວເຄື່ອນໄຫວແລະການເຄື່ອນໄຫວທີ່ມີຄວາມສູງສຸດ.

ຄວາມແຂງແຮງທີ່ອຸນຫະພູມສູງ - ບັນທຶກຄວາມສັນຍາມເຄື່ອນໄຫວຈົນ 1093°C (2000°F).

ຄວາມສັນຍາມທີ່ດີ - ບັນທຶກການເຄື່ອນໄຫວທີ່ສະຫງົບ, ບໍ່ມີຂ້ອຍ, ແລະ porosity ທີ່ໜ້ອຍທີ່ສຸດ.

ຄວາມຕ້ອງການການເຄື່ອນໄຫວທີ່ເປັນกรົດ - ອອກສະຫງົບການເຄື່ອນໄຫວໂດຍ hydrochloric acid, sulfuric acid, nitric acid, ແລະ seawater corrosion.

ຄວາມແຂງແຮງທີ່ຍາວ - ອອກສະຫງົບສຳລັບສິ່ງແວດລ້ອມທີ່ຮ້າຍແຮງ, ບັນທຶກຄວາມຍາວໃນການໃຊ້.

ສະຖານະແລະສະເພາະຂອງອຸດມະຊາດ

絲เชื่อม ERNiCrMo-4 ของเราได้มาตรฐานคุณภาพสากล ซึ่งรับประกันความน่าเชื่อถือและความเข้ากันได้กับการใช้งานในอุตสาหกรรมต่างๆ

ສະເພາະສະຖານະ

AWS A5.14 ERNiCrMo-4

UNS Number N10276

ASTM Standard ASTM B574, ASTM B575

ISO Standard ISO 18274: NiCr15Mo16Fe6W4

ด้วยใบรับรองเหล่านี้ 丝丝เชื่อมของเรามีประสิทธิภาพ เสถียรภาพ และเป็นไปตามข้อกำหนดสำหรับการเชื่อมที่สำคัญ

ການໃຊ້ເສື່ອໂຍດ ERNiCrMo-4 (C-276)

ERNiCrMo-4 丝丝เชื่อมถูกใช้อย่างแพร่หลายในอุตสาหกรรมที่ต้องการความต้านทานการกัดกร่อนสูงและความทนทานต่ออุณหภูมิสุดขั้ว

1. การแปรรูปเคมีและการกลั่นน้ำมัน

ถังเก็บและท่อส่ง – ป้องกันการกัดกร่อนจากกรดและสารเคมีในสภาพแวดล้อมที่รุนแรง

เครื่องปฏิกรณ์และการแลกเปลี่ยนความร้อน – รับประกันการทำงานที่น่าเชื่อถือในปฏิกิริยาเคมีที่อุณหภูมิสูง

ปั๊มและวาล์ว – คงทนระยะยาวในระบบของเหลวที่กัดกร่อน

2. ບໍລິສັດນ้ำມັນ & ກັສສູ້

แท่นขุดเจาะนอกชายฝั่งและท่อส่ง – ต้านทานการกัดกร่อนจากน้ำทะเลและการเปราะตัวจากไฮโดรเจน

อุปกรณ์เก็บและแปรรูปก๊าซธรรมชาติเหลว (LNG) – ทำงานได้ดีในสภาพอากาศที่เย็นจัด

โรงกลั่นและหน่วยแตกห่วงโซ่ทางเคมี – มีความต้านทานการออกซิเดชันที่อุณหภูมิสูง

3. ບໍລິສັດຜົນໄຟ & ອຸ່ນພາບ

ເຄື່ອງປະຕິກຳແລະລະບົບແປງຄວາມຮ້ອນ – ຕ້ານໄດ້ກັບຄວາມຮ້ອນສູງແລະການປ່ຽນແປງຄວາມຮ້ອນ.

ລະບົບການຫຼີ້ນກາຊ (FGD) – ກຸ່ມຄໆ້ຍກັບການອອກແຜ່ຂອງกรดແລະການເສຍທຶນ.

ສ່ວນປະກອບຂອງເຄື່ອງປະຕິກຳນິວເຄລີ – ຕ້ານໄດ້ກັບການສັນລະເມີນແລະຄວາມພໍ່ຍິງຂອງຄວາມຮ້ອນສູງ.

4. ອຸດິສັນຕະພາບເຮືອ ແລະ ມາຣິນ

ສ່ວນປະກອບຂອງເຄື່ອງບິນແລະຮູບແບບເຮືອບິນ – ຜູ້ໃຫ້ຄວາມຕ້ານການໂອξິເດຊັນທີ່ດີທີ່ສຸດໃນຄວາມຮ້ອນສູງ.

ການສ້າງເຮືອແລະລະບົບທີ່ນໍ້າເຄົາ – ຄວາມປ່ອງກັນການເສຍທຶນຈາກນໍ້າເຄົາ.

5. ຄະນິກການປະຕິວັດອາຫານ ແລະ ພັດທະນາໄຂ້

ອຸປະກອນສະຖິຕິແລະທີ່ນໍ້າ– ຕັ້ງຄວາມເປັນໄປໂດຍບໍ່ມີການເຄື່ອມແລະບໍ່ມີການປະກາດ.

ເຫດຜົນໃນການເລືອກເສັ້ນໂຍດERNiCrMo-4 (C-276) ຂອງພວກເຮົາ?

ລາຄາອອນລາຍທີ່ດີທີ່ສຸດ – ເດີ້ยวລາຄາສົ່ງຈາກโรงงาน.

ສ່ວນຫຼຸດສຳລັບການສັ່ງຊື້ຫຼາຍ – ລາຄາພິเศษສຳລັບການສັ່ງຊື້ຈຳນວນຫຼາຍ.

ການສົ່ງທີ່ວັນແລະໝັ້ນຄື – ການສົ່ງອອກສຳລັບສາກົນສາກົນ.

ເສົາ້ທີ່ມີຄຸນພາບສູງແລະຖືກຢືນຢັນ – ຢູ່ໃນປະເທດ AWS, ASTM, ແລະ ISO.

ການເӨົາແລະຂະໜາດພິເສດ – ມີໃນຮູບແບບສະປຸ້ມ, ກົ້ວ, ແລະສັ່ງຕັດຕາມຄວາມຍາວ.

ຄວາມສ້າງສຸກຂອງສິນຄ້າທີ່ຈະສົ່ງ – ສໍາລັບການສົ່ງອອກທົ່ວໄປ.

ສັ່ງຊື້ ERNiCrMo-4 (C-276) ໂຫລດວິນາທີ່ – ລາຄາດີທີ່ສຸດອອນໄລນ์ & ການສົ່ງສິນຄ້າເรົາ!

ກຳລັງຄົ້ນຫາໂຫລດ ERNiCrMo-4 ຄູณພະຍາ Thai ໃນລາຄາອອນໄລນ์ທີ່ດີທີ່ສຸດ? ພວກເຮົາມີການສະໜອງຈາກແຟັກຕູ, ສ່ວນຫຼຸດຫຼາຍ, ແລະການສົ່ງອອກສິນຄ້າສຳລັບຄວາມຕ້ອງການວິນາທີ່ອຸດູສາຫະກຳຂອງທ່ານ.

คำถามທີ່ຖົກຖາມบໍ່ຫຼາຍ (FAQs):

ເວລາສົ່ງສິນຄ້າຈະຍາວປານໃດ?

ມັນຕັດແຍກໂດຍລົງທຶນຂອງຄຳສັ່ງ, 10-30 ມື້ສຳລັບຄຳສັ່ງນ້ອຍ. ສຳລັບຄຳສັ່ງໃຫຍ່, ເວລາ 60 ມື້.

ທ່ານຮັບການผลิต OEM/ODM ຫຼືບໍ່?

ແມ່ນ! ພວກເຮົາຮັບการผลิต OEM/ODM. ທ່ານສາມາດສົ່ງສະໝຸກຫຼືແຜນພາບມາໃຫ້ພວກເຮົາ.

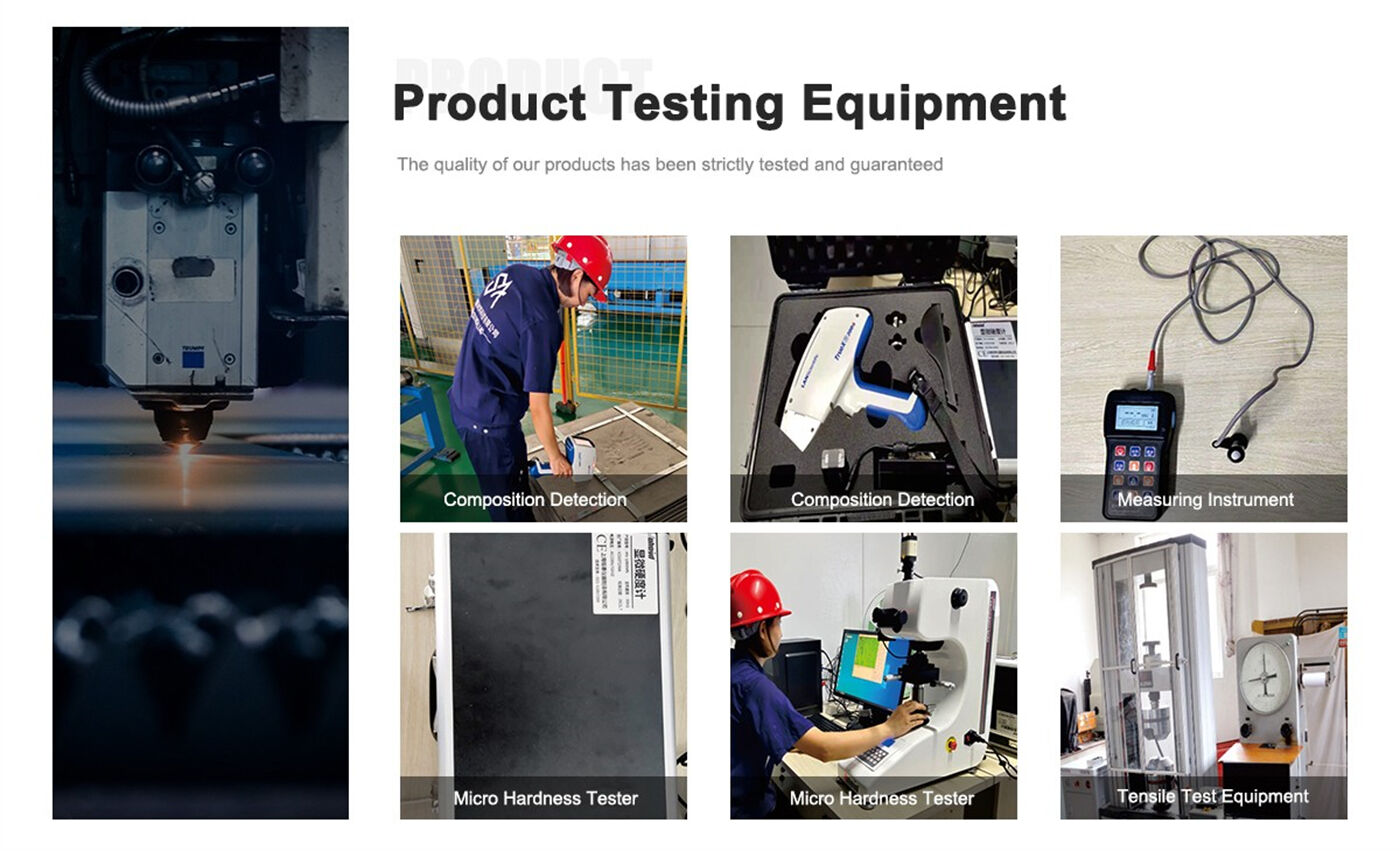

ທ່ານຄົ້ນຄວ້າຄຸณພາບຂອງສິນຄ້າແນວໃດ? ຄุณສິດເຄມີຂອງສິນຄ້າປະກອບກັບຄຸນພາບທີ່ຖືກຕ້ອງບໍ່?

ດ້ວຍທິມຄຸນພາບຊ່ຽວຊານ, ການແຜນການຄຸນພາບສິນຄ້າແໜ່ງ, ການປະເທດແລະການปรຸບປຸງຢູ່ເสมົ່າ, ພວກເຮົາຈະອອກໃບສັນຍາຄຸນພາບສິນຄ້າ, ປົກລົມການວິເຄາະເຄມີ.

ບໍລິສັດຂອງທ່ານສາມາດໃຫ້ຂໍ້ມູນ媄ຸນແລະແຜນພາບລາຍລະອຽດໄດ້ບໍ່?

ແມ່ນ, ທ່ານສາມາດ. ກະລຸນາເວົ້າໃຫ້ພວກເຮົາຮູ້ວ່າທ່ານຕ້ອງການສິນຄ້າແລະການໃຊ້ງານໃດ, ແລະພວກເຮົາຈະສົ່ງຂໍ້ມູນ媄ຸນແລະແຜນພາບລາຍລະອຽດມາໃຫ້ທ່ານສຳລັບການ昡ວນແລະຢືນຢັນ.

ທ່ານจັດການບໍລິການກ່ອນຂາຍແລະຫຼັງຂາຍແນວໃດ?

ພວກເຮົາມີທິມຄ້າຊ່ຽວຊານທີ່ຈະຮູບແບບໜຶ່ງຕ່ອໜຶ່ງເພື່ອค໋້າອຳປາຍຄຳສັ່ງຂອງທ່ານ, ແລະຖ້າທ່ານມີຄຳຖາມໃດໆ, ລາວສາມາດຕອບຄຳຖາມນັ້ນສຳລັບທ່ານ!

ຂ້ອຍສາມາດມາเยົ່ນທະເລີງຂອງທ່ານກ່ອນສັ່ງຊື້ໄດ້ບໍ່?

ແມ່ນ, ທ່ານສາມາດມາเยົ່ນທະເລີງຂອງພວກເຮົາໄດ້. ພວກເຮົາສຸກສານທີ່ຈະມີຄວາມສຳຫຼັບສຳຫຼວງໃນການຮູ້จັກກັນ.

ທະເລີງຜະລິດຕະນິ button ຂອງທ່ານຢູ່ไหน?

ພວກເຮົາຜະລິດສິນຄ້າໃນແຂວງ Jiangsu, ປະເທດຈີນ ແລະ ສົ່ງອອກຈາກຈີນໄປປະເທດຂອງທ່ານໂດຍເວລາສັ້ນທີ່ສຸດ, ທີ່ສຸດແມ່ນການລັບຖານຂອງສິນຄ້າແລະຈຳນວນ.

ທ່ານສາມາດສົ່ງສ໊າມຸນໄດ້ບໍ່?

ແມ່ນ, ພວກເຮົາສາມາດ.