Lightweight and Conductive Foam Copper for Advanced EMI Shielding in Aerospace and Telecommunications

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

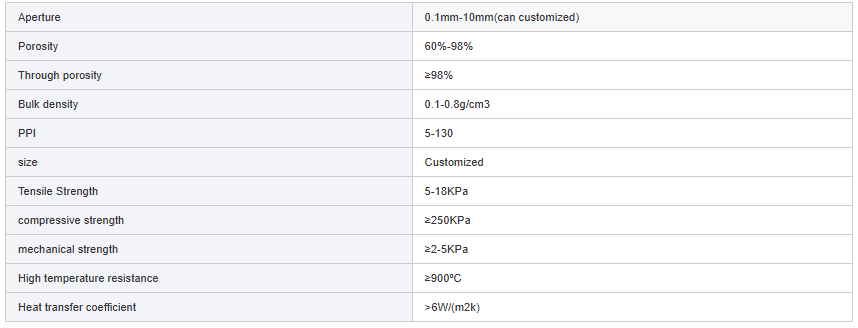

- Specification

- About Us

- FAQs

- Recommended Products

-

EMI Shielding for Aerospace Electronics

- Modern aircraft and spacecraft rely on highly sensitive electronic systems that must be protected from EMI to ensure accurate data transmission and operational safety.

- Foam copper is used in shielded enclosures, circuit board housings, and aircraft communication systems, reducing interference and enhancing system reliability.

-

Telecommunications and 5G Infrastructure

- With the rapid deployment of 5G networks and satellite communication, shielding against electromagnetic interference is crucial for stable connections.

- Foam copper serves as a lightweight and highly conductive EMI shield in base stations, antennas, and network servers, improving signal clarity and transmission efficiency.

-

Electronic Device Enclosures and Signal Integrity

- In consumer electronics and industrial devices, EMI shielding helps prevent signal disruptions and performance degradation.

- Foam copper is used in mobile phones, tablets, GPS devices, and military-grade electronics to ensure consistent functionality in high-interference environments.

-

Automotive Radar and Electric Vehicles (EVs)

- As vehicles become increasingly connected with autonomous driving systems and wireless communication, EMI shielding is essential.

- Foam copper enhances electromagnetic compatibility in radar sensors, onboard computers, and EV battery systems, ensuring efficient and interference-free operation.

- High Conductivity for Effective Shielding: Customers require high-performance materials that minimize electromagnetic interference without compromising electrical conductivity.

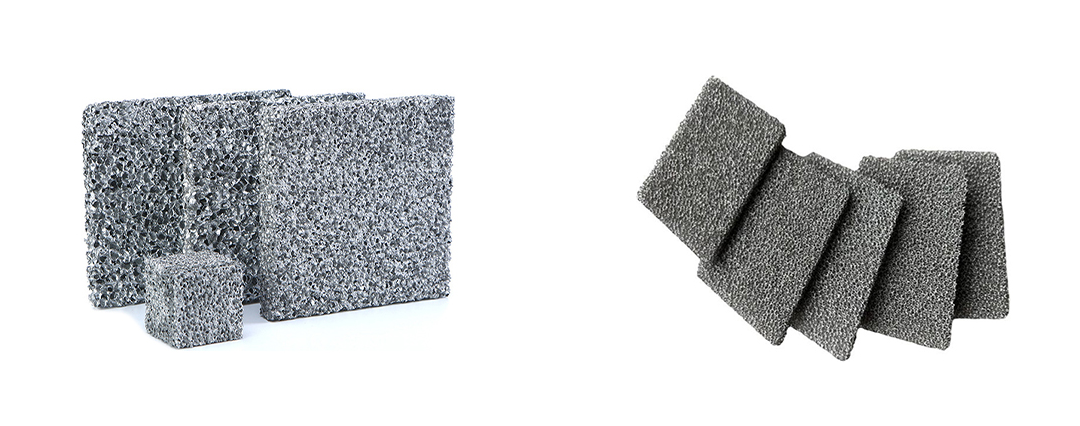

- Lightweight Design for Aerospace Efficiency: In aerospace applications, weight reduction is crucial. Foam copper provides strong EMI shielding with minimal added weight.

- Flexible and Customizable Structures: Its porous structure and easy adaptability allow for use in complex designs and space-limited applications.

- Durability and Corrosion Resistance: Foam copper offers long-term reliability, even in harsh environmental conditions such as high altitudes and extreme temperatures.

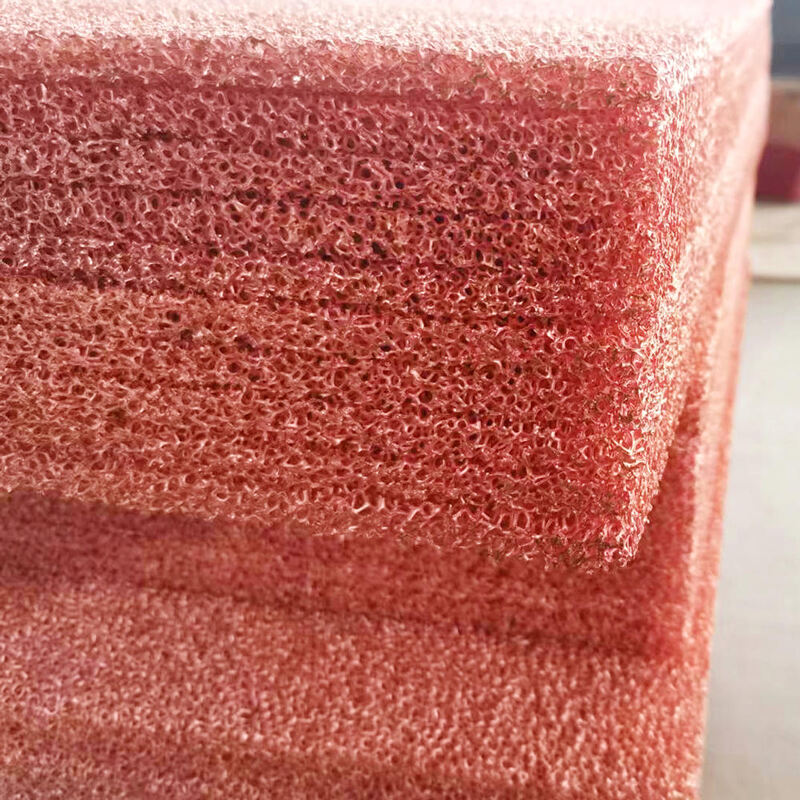

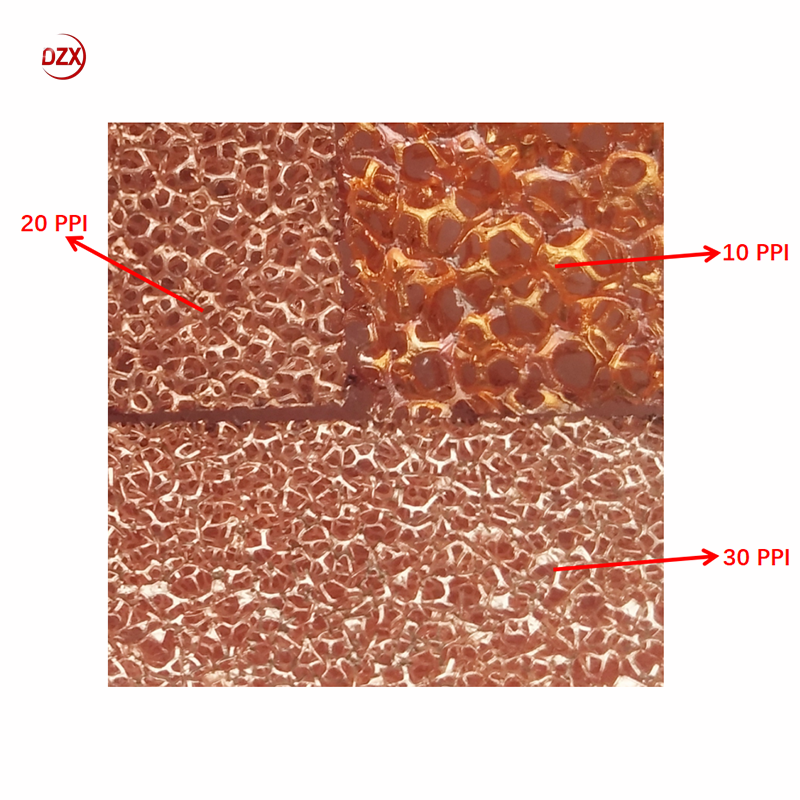

As the demand for high-speed communication and advanced aerospace technologies grows, electromagnetic interference (EMI) shielding has become a critical requirement. Foam copper is an innovative material that combines lightweight properties, excellent electrical conductivity, and superior shielding performance, making it ideal for aerospace and telecommunications applications. Its porous structure allows for efficient EMI absorption while maintaining structural integrity and flexibility.

Applications of Foam Copper in EMI Shielding

Meeting Industry Needs with Foam Copper Solutions

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.