니켈 합금 하스탈로이 C-22 라운드 바 – 항공우주 및 발전소에 완벽

우리는 공장 직거래 가격과 대량 주문에 대한 특별 할인을 제공합니다. 소량 또는 대량이 필요하더라도, 우리의 제품은 전 세계의 산업 프로젝트에 신속하게 배송되어 안정적인 공급을 보장합니다.

- 개요

- 사양

- 응용 프로그램

- 자주 묻는 질문

- 추천 상품

- 고온 강도와 산화에 대한 저항력 때문에 항공기 및 우주선 부품에 사용됩니다.

- 터빈 엔진 부품, 연료 시스템 및 배기 덕트에 적합합니다.

- 고온과 부식성 가스에 노출되는 환경이 일반적인 원자력 및 열병합 발전소에서 필수적입니다.

- 열교환기, 보일러 및 배관 시스템에서 사용됩니다.

- 산성 및 산화성 화학 물질을 처리하는 장비에 적합하며, 반응기, 분류탑 및 증발기에 사용됩니다.

- 염산, 황산 및 염소가 포함된 용액에 대한 뛰어난 내식성을 지니고 있습니다.

- 바닷물과 염수 환경에 적합하며, 염수 노출로부터 부식을 방지합니다.

- 조선업, 역삼투압 설비 및 해상 채굴 플랫폼에 적용됩니다.

- Acidic 가스에 대한 우수한 저항력으로 인해 스크러버, 폐수 처리장 및 연기 탈황 시스템에 사용됩니다.

- 원료 (니켈, 모리브덴, 크롬 및 철)이 진공 또는 전기로에서 함께 녹여집니다.

- 합금은 균일한 결정 구조와 기계적 강도를 위해 단조되고 뜨거운 압연을 통해 원형 막대 형태로 가공됩니다.

- 소성 열처리를 통해 재료의 부식 저항性和 기계적 특성이 향상됩니다.

- 정밀 가공으로 차원적 정확성과 매끄러운 표면 마감이 보장됩니다.

- 광동, 밝은 표면 또는 검은색 표면 마감으로 제공됩니다.

- 비파괴 검사(NDT), 초음파 검사 및 경도 검사가 ASTM B574 표준을 충족하기 위해 수행됩니다.

- 항공우주 및 에너지 부문의 급속한 확장이 하스텔로이 C-22와 같은 고성능 니켈 합금에 대한 수요를 견인하고 있습니다.

- 산업에서는 특정 엔지니어링 요구 사항을 충족하기 위해 맞춤형 크기, 직경 및 표면 마감의 라운드 바가 필요합니다.

- 대량 구매 옵션과 공장 직송 공급은 산업이 비용을 절감하면서 고품질의 재료를 보장할 수 있도록 도와줍니다.

- 신뢰할 수 있는 공급망은 국제 고객에게 적시에 배송하여 대규모 프로젝트를 지원합니다.

하스텔로이 C-22 라운드 바는 높은 내식성과 기계적 강도가 필요한 산업에서 필수적인 재료입니다. 극한 환경에서 우수한 성능을 발휘하여 이 니켈 합금 라운드 바는 항공우주, 발전소 및 기타 엄격한 응용 분야에서 널리 사용됩니다. 니켈, 몰리브데넘, 크롬 및 철의 조합으로 하스텔로이 C-22는 산화제와 환원제에 대해 뛰어난 저항성을 가지며, 이를 통해 엔지니어와 제조업체들이 선호하는 선택이 됩니다.

하스텔로이 C-22란?

Hastelloy C-22 (UNS N06022)는 다양한 부식 조건에 대한 저항성이 향상된 니켈 기반 초합금입니다. 그 구성은 공격적인 화학적 환경에서도 점식 부식, 균열 부식 및 응력 부식 파괴에 대해 매우 높은 내성을 제공합니다.

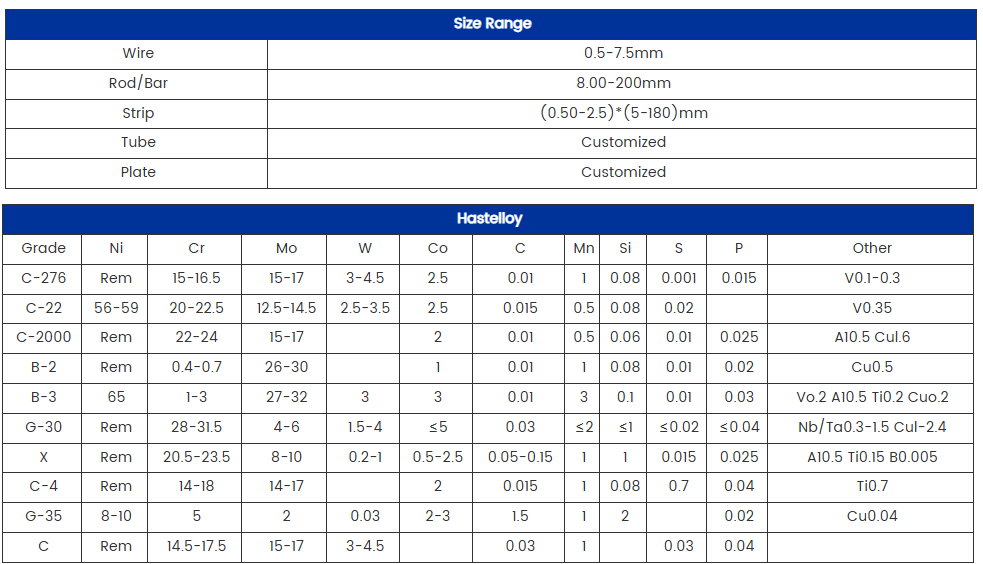

Hastelloy C-22의 화학적 조성

| 원소 | 구성 (%) |

|---|---|

| 니켈 (Ni) | 밸런스 |

| 몰리브덴 (Mo) | 12.5 - 14.5 |

| 크롬 (Cr) | 20.0 - 22.5 |

| 철 (Fe) | 2.0 - 6.0 |

| 코발트 (Co) | ≤ 2.5 |

| 텅스텐 (W) | 2.5 - 3.5 |

| 탄소 (C) | ≤ 0.015 |

| 망간 (Mn) | ≤ 0.50 |

| 규소 (Si) | ≤ 0.08 |

| 인 (P) | ≤ 0.02 |

| 황 (S) | ≤ 0.02 |

Hastelloy C-22 라운드 바의 응용 분야

우수한 내식성과 기계적 특성 때문에 Hastelloy C-22 라운드 바는 광범위하게 사용됩니다:

1. 항공 우주 산업

2. 발전소

3. 화학 처리 산업

4. 해양 및 해상 응용

5. 오염 통제 및 환경 시스템

Hastelloy C-22 라운드 바 제조 공정

Hastelloy C-22 라운드 바는 우수한 품질과 내구성을 보장하기 위해 엄격한 생산 공정을 통해 제작됩니다:

1. 용해 및 합금화

2. 단조 및 압연

3. 열처리

4. 가공 및 마무리

5. 품질 검사

사용자 수요 및 시장 동향

1. 항공우주 및 발전 부문에서의 수요 증가

2. 맞춤형 및 OEM 공급 선호

3. 경쟁력 있는 가격 및 대량 주문

4. 글로벌 배포 및 신속한 배송

질문:

배송시간은 얼마인가요?

주문량에 따라 다릅니다. 소량 주문은 10-30일이 소요됩니다. 대량 주문의 경우 60일이 걸립니다.

OEM/ODM 생산을 하시나요?

네! 우리는 OEM/ODM 생산을 합니다. 샘플이나 도면을 보내주시면 됩니다.

제품 품질은 어떻게 관리하나요? 제품의 화학적 특성은 품질 기준을 충족합니까?

전문적인 품질 팀, 선진적인 제품 품질 계획, 엄격한 실행 및 지속적인 개선을 통해 제품 품질 검사 증명서를 발행하며, 이는 화학 분석 보고서를 포함합니다.

귀사에서 상세한 기술 데이터와 도면을 제공할 수 있나요?

네, 가능합니다. 필요한 제품과 응용 분야를 알려주시면 상세한 기술 데이터와 도면을 보내드리겠습니다. 평가와 확인을 위해 제공됩니다.

판매 전후 서비스는 어떻게 처리하나요?

우리는 전문적인 비즈니스 팀을 보유하고 있으며, 담당자가 1:1로 귀하의 제품 요구 사항을 지원합니다. 질문이 있으면 그분이 답변해드립니다!

주문하기 전에 공장 방문이 가능한가요?

네, 공장을 방문하셔도 됩니다. 서로 알아갈 수 있는 기회를 환영합니다.

생산 기지는 어디에 있나요?

우리는 중국 장수에서 제품을 제조하며, 가능한 한 빨리 중국에서 귀하의 국가로 발송합니다. 이는 일반적으로 제품 요구 사항과 수량에 따라 다릅니다.

샘플 보내실 수 있나요?

그래, 할 수 있어