J-Type Thermocouple Bare Wire (Fe-CuNi) for Reliable Temperature Sensing

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

- Specification

- Off-the-shelf supply

- FAQs

- Recommended Products

J-Type thermocouple bare wire, composed of Iron (Fe) and Copper-Nickel (CuNi), is a widely used temperature sensing material known for its accuracy, stability, and cost-effectiveness. It is commonly used in industrial applications that require reliable temperature monitoring, especially in environments where oxidizing conditions are minimal.

This article explores the material composition, applications, and key user considerations for using J-Type thermocouple bare wire in various industries.

Material Composition and Characteristics

J-Type thermocouple wire consists of two different metal alloys:

Positive Leg: Iron (Fe)

Negative Leg: Copper-Nickel (CuNi)

Key Features

Moderate Temperature Range: Operates between -210°C and 760°C (-346°F to 1,400°F), making it suitable for many industrial applications.

High Sensitivity: Provides an EMF output of approximately 55 µV/°C, allowing for precise temperature measurement.

Good Accuracy: Delivers stable performance in controlled environments with minimal oxidation exposure.

Cost-Effective: More affordable than noble metal thermocouples while still offering reliable thermal sensing.

Limited Oxidation Resistance: Performs well in inert or mildly reducing environments but is susceptible to oxidation at high temperatures.

Applications of J-Type Thermocouple Bare Wire

J-Type thermocouple wire is widely used in industries that require dependable and cost-effective temperature measurement solutions.

Manufacturing and Metal Processing

Heat Treatment and Furnaces – Used for temperature control in annealing, tempering, and hardening processes.

Plastic and Rubber Production – Essential for maintaining precise thermal conditions in injection molding and extrusion processes.

Foundries and Metal Casting – Ensures accurate temperature measurement during melting and solidification.

HVAC and Industrial Equipment

Boilers and Ovens – Monitors temperature variations in commercial and industrial heating systems.

Refrigeration and Air Conditioning – Used in cooling systems to ensure proper thermal regulation.

Automated Process Control – Supports temperature monitoring in industrial machinery and automation systems.

Energy and Power Generation

Steam and Gas Turbines – Provides accurate temperature readings in power plant operations.

Renewable Energy – Applied in biomass and geothermal energy systems for efficient heat management.

Meeting Industrial User Needs

Users in industrial settings require thermocouples that provide reliable and accurate temperature readings under various conditions. The key factors to consider when selecting J-Type thermocouple bare wire include:

Accuracy and Calibration

Offers Class 1 accuracy of ±1.5°C or 0.4% of the temperature range.

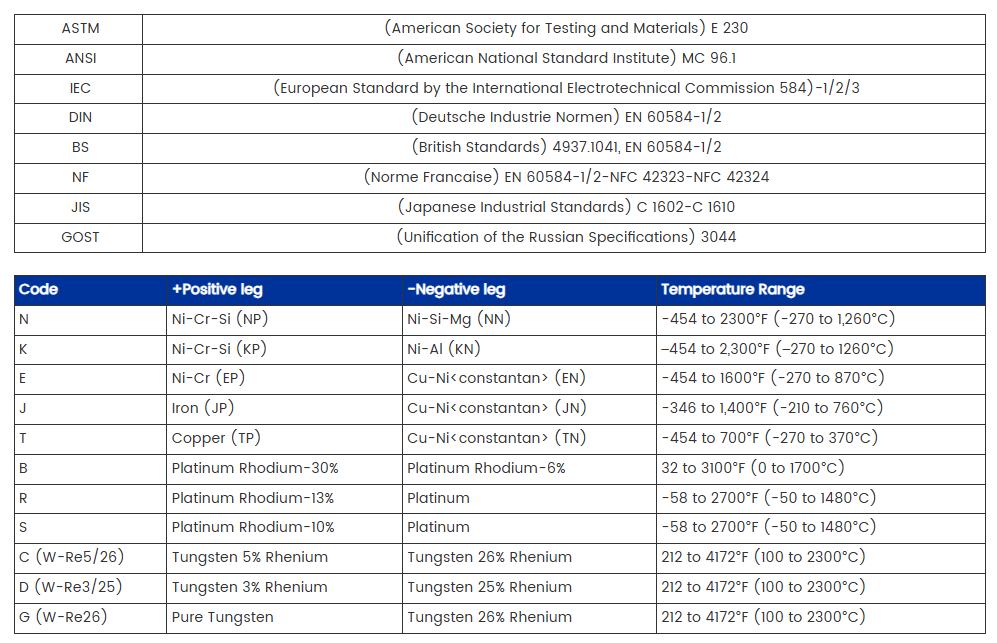

Available in compliance with IEC 60584-1, ANSI, and ASTM E230 calibration standards.

Wire Gauge and Insulation

Available in multiple wire diameters, such as 0.25mm, 0.5mm, and 1.0mm, to suit different response time requirements.

Can be used bare or insulated with materials like fiberglass, PVC, or PTFE for added protection.

Environmental Considerations

Performs well in inert and reducing environments but is prone to oxidation at temperatures above 540°C.

Protective sheaths like stainless steel or Inconel are recommended for prolonged use in high-temperature environments.

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.