Filo per saldatura ERNiCrMo-4 (C-276) all'ingrosso – Fornitura di un produttore fidato

Altro: ERNiCrMo-3, ERNiCrMo-4, ERNiCrMo-13, ERNiCrFe-3, ERNiCrFe-7, ERNiCr-3, ERNiCr-7, ERNiCu-7, ERNi-1, ER70S-6.

Offriamo prezzi diretti di fabbrica con sconti speciali su ordini bulk. Che tu abbia bisogno di quantità piccole o grandi, il nostro filo per saldatura ERNiCrMo-4 è disponibile per spedizione immediata, garantendo un approvvigionamento affidabile per progetti industriali in tutto il mondo.

- Panoramica

- Applicazioni

- Domande frequenti

- Prodotti Consigliati

Il filo per saldatura ERNiCrMo-4 (C-276) è un lega a base di nichel alto prestazione progettata per la saldatura di Hastelloy C-276 e altre leghe resistenti alla corrosione. Viene utilizzato ampiamente in settori che richiedono una resistenza eccezionale alla corrosione, temperature elevate e ambienti chimici severi.

Come fabricante e fornitore di fiducia, offriamo filo per saldatura ERNiCrMo-4 al dettaglio a prezzi competitivi. Con sconti su ordini bulk e spedizione internazionale, il nostro filo per saldatura garantisce qualità superiore, affidabilità e durabilità per applicazioni industriali.

Panoramica del materiale: Proprietà del filo per saldatura ERNiCrMo-4 (C-276)

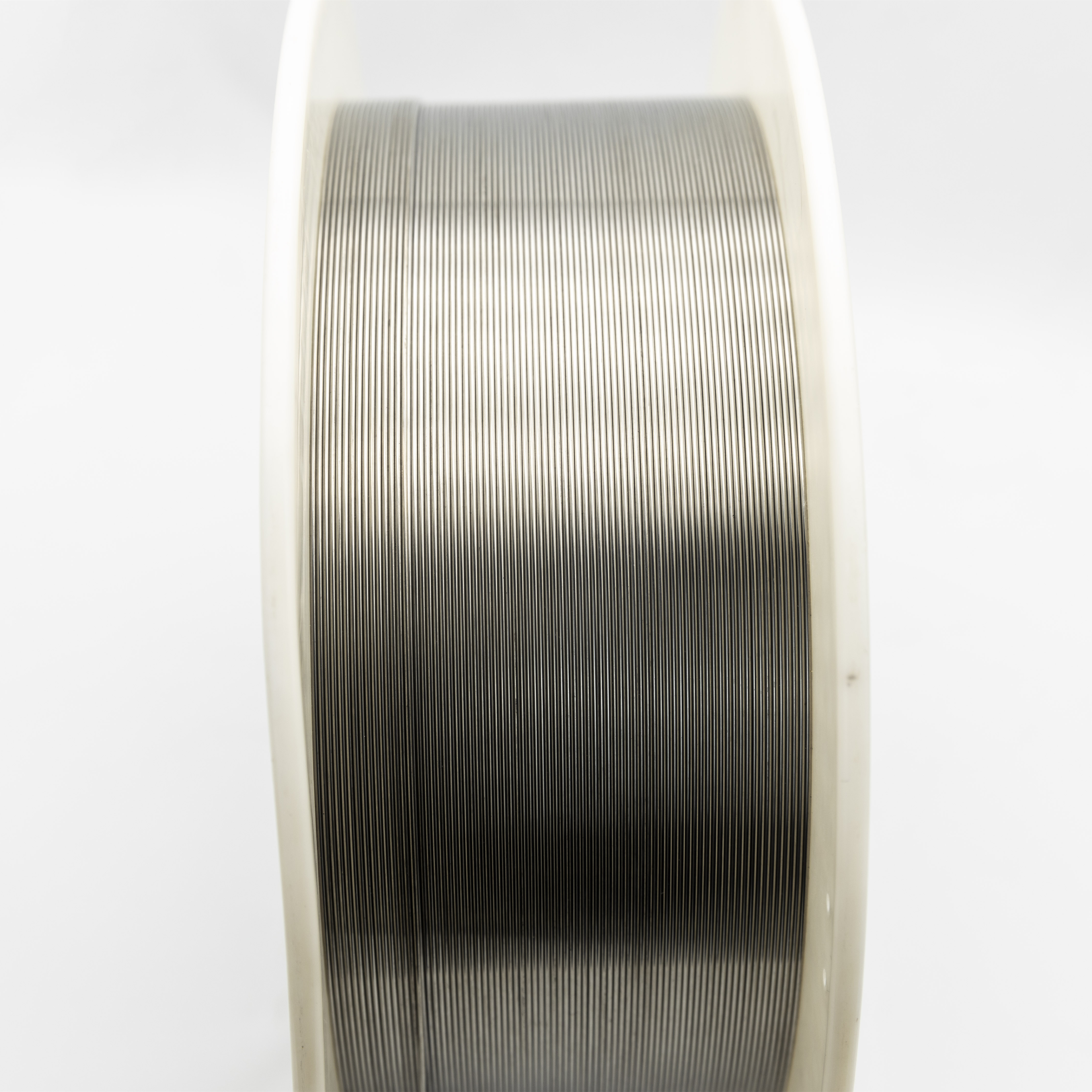

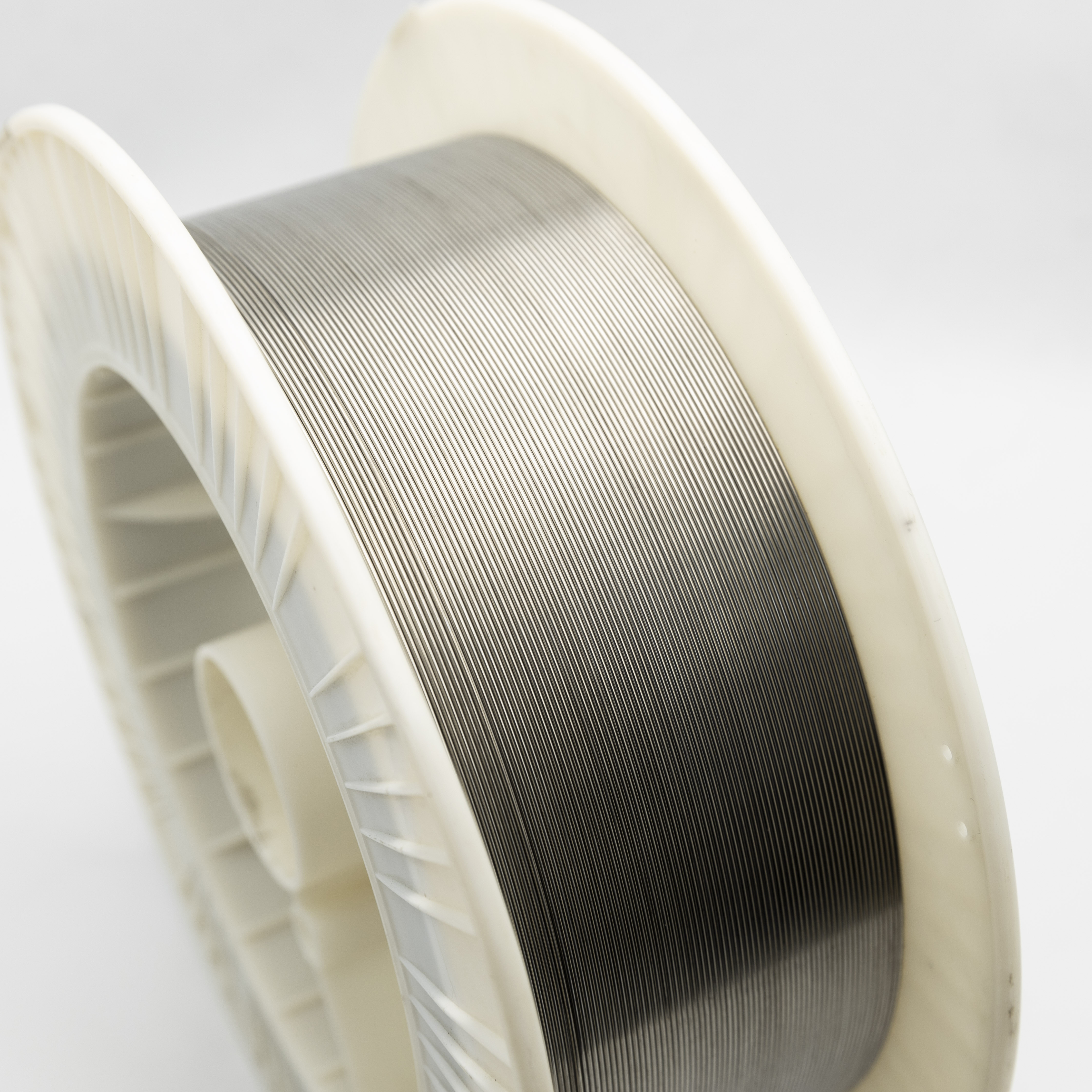

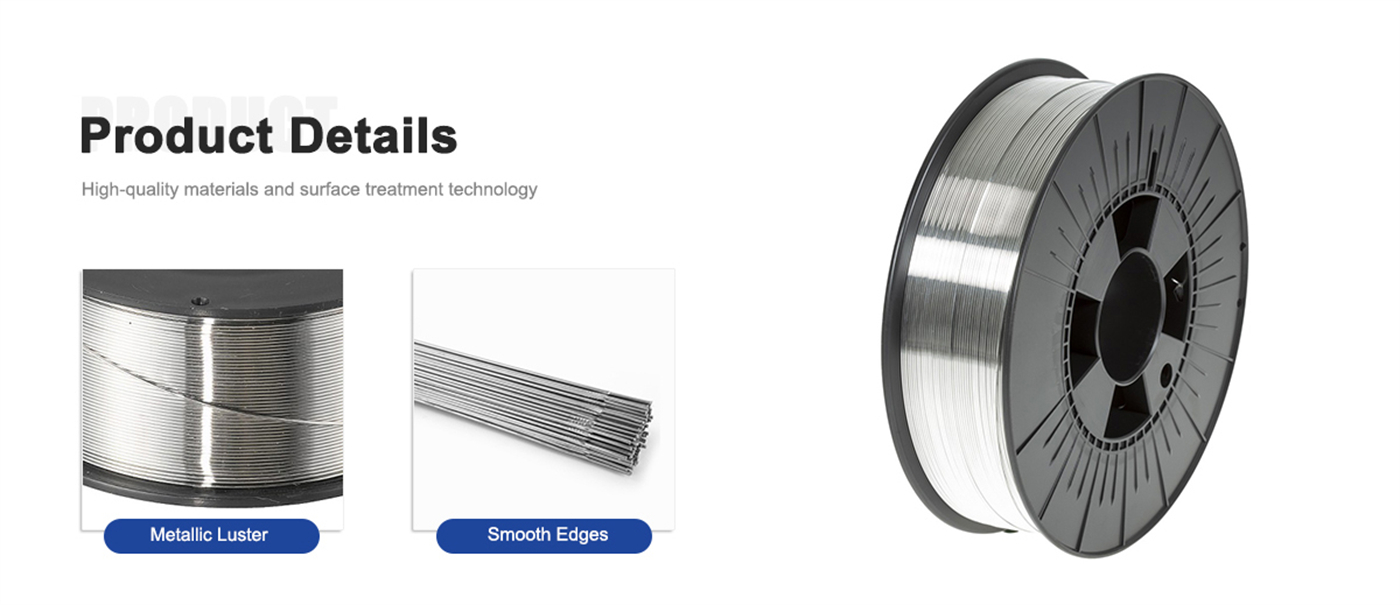

ERNiCrMo-4 è un'alluminio di nichel-cromo-molibdeno con l'aggiunta di ferro e tungsteno, che lo rende altamente resistente all'ossidazione, alla corrosione a punti, alla corrosione intercristallina e alla crepatura per corrosione sotto sforzo. È specificamente progettato per applicazioni di saldatura in ambienti chimici aggressivi.

Caratteristiche principali del filo per saldatura ERNiCrMo-4 (C-276)

✔ Ottima resistenza alla corrosione – Si comporta eccezionalmente bene in ambienti acidi, ossidanti e ricchi di cloruri.

✔ Resistenza ad alte temperature – Mantiene la stabilità meccanica a temperature estreme fino a 1093°C (2000°F).

✔ Eccellente saldabilità – Garantisce saldature lisce, senza crepe e senza difetti.

✔ Resistenza chimica e agli acidi – Resiste all'acido cloridrico, all'acido solforico, all'acido nitrico e alla corrosione causata dall'acqua di mare.

✔ Prestazioni durature – Progettato per ambienti industriali severi e vita operativa prolungata.

Norme e Specifiche dell'Industria

Il nostro filo per saldatura ERNiCrMo-4 soddisfa gli standard globali dell'industria, garantendo la sua compatibilità e affidabilità per applicazioni critiche.

Specifiche Standard

AWS A5.14 ERNiCrMo-4

Numero UNS N10276

Norma ASTM ASTM B574, ASTM B575

Norma ISO ISO 18274: NiCr15Mo16Fe6W4

Queste certificazioni garantiscono che il nostro filo per saldatura rispetti i requisiti di qualità, resistenza e resistenza alla corrosione più elevati.

Applicazioni del filo per saldatura ERNiCrMo-4 (C-276)

Il filo per saldatura ERNiCrMo-4 è ampiamente utilizzato in settori industriali critici che richiedono una straordinaria resistenza alla corrosione, durata a temperature elevate e prestazioni a lungo termine.

1. Chimica e Petrochimica

Serbatoi di Memoria e Pipeline - Protegge contro la corrosione chimica da acidi e solventi.

Reattori e Scambiatori di Calore - Garantisce un buon rendimento a lungo termine in ambienti estremi.

Pompe e Valvole - Aumenta la durata in sistemi di fluidi corrosivi.

2. Industria del petrolio e del gas

Piattaforme di Trivellazione Offshore e Pipeline - Resiste alla corrosione delle acque marine e all'embrittamento da idrogeno.

Attrezzature per l'Immagazzinamento e il Processamento del GNL - Funziona bene in condizioni a bassa temperatura e criogenica.

Raffinerie e Unità di Fratturazione Catalitica - Resiste all'ossidazione e alla corrosione ad alta temperatura.

3. Centrali Elettriche e Settore Energetico

Caldaie e Scambiatori di Calore - Adatti al ciclo termico e al calore estremo.

Sistemi di Dessulfurizzazione dei Gas di Scarico (FGD) - Previene la corrosione da emissioni acide.

Componenti del Reattore Nucleare – Fornisce resistenza alla radiazione e alle alte temperature.

4. Ingegneria Aerospaziale e Marittima

Componenti del Motore a Reazione e Strutture Aeronautiche – Garantisce resistenza all'ossidazione ad alta temperatura.

Costruzione Navale e Sistemi di Tubazioni per Acqua di Mare – Protegge contro la corrosione e la degradazione causate dall'acqua salata.

5. Industria Alimentare e Farmaceutica

Attrezzature per la Sterilizzazione e Tubazioni Igiene – Garantisce prestazioni libere da contaminazione e resistenti alla corrosione.

Perché Scegliere il nostro Filo da Saldatura ERNiCrMo-4 (C-276)?

Produttore di Fiducia e Fornitura Diretta – Prezzi garantiti di fabbrica e qualità premium.

Sconti al Dettaglio e su Ordini Ingrossati – Prezzi speciali per ordini di grandi volumi.

Spedizione Veloce e Globale – Opzioni di consegna affidabili in tutto il mondo.

Materiale Certificato e Di Alta Qualità – Rispetta i standard AWS, ASTM e ISO.

Dimensioni Personalizzate per Ordini – Disponibili in bobine, rulli e opzioni tagliate alla lunghezza.

Disponibilità di Magazzino Garantita – Pronta per la spedizione immediata.

Domande frequenti:

Quanto tempo ci vuole per consegnare?

Dipende dalla quantità dell'ordine, 10-30 giorni per ordini piccoli. Per ordini grandi, ci vogliono 60 giorni.

Accettate la produzione OEM/ODM?

Sì! Accettiamo la produzione OEM/ODM. Potete inviarci i vostri campioni o disegni.

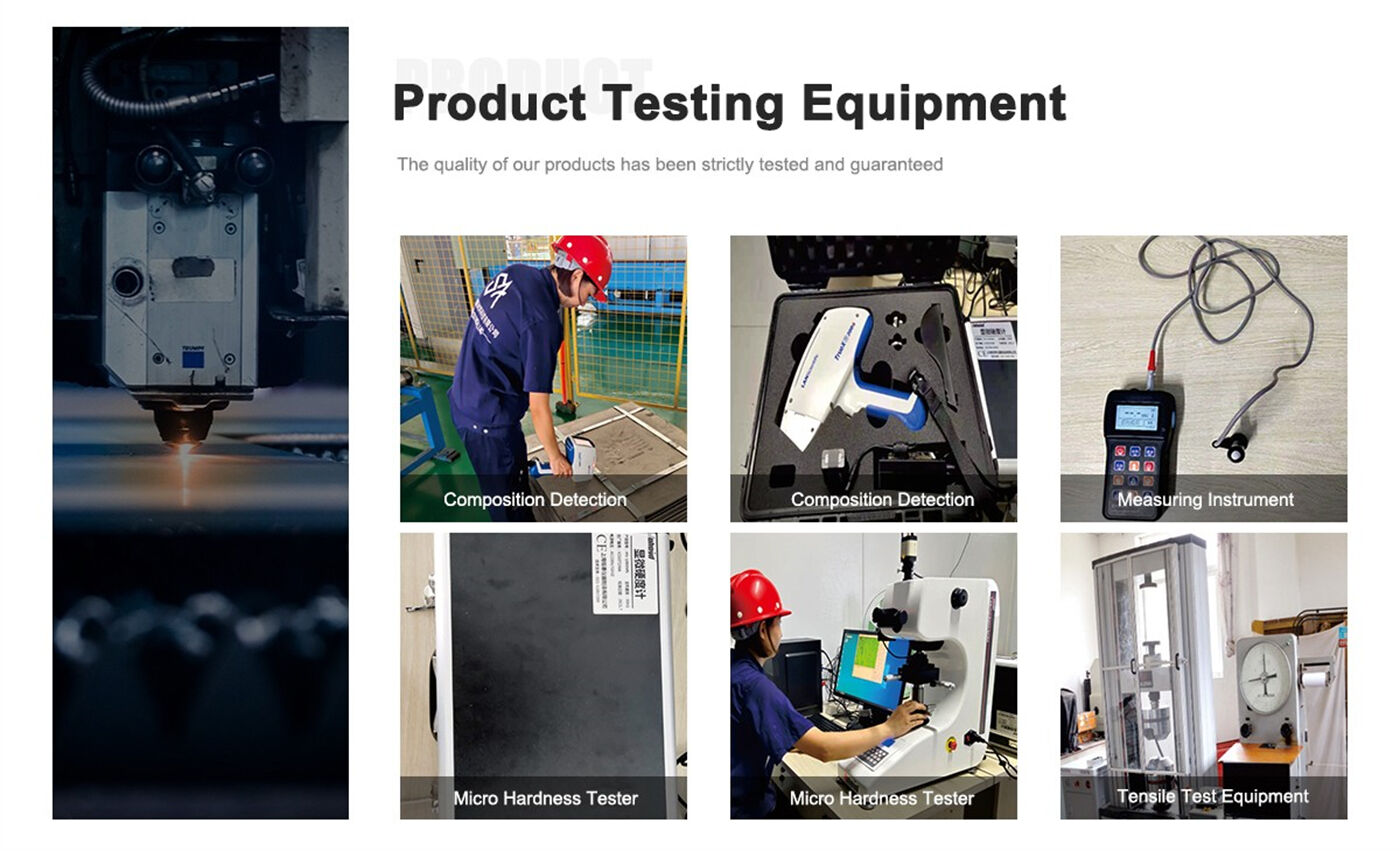

Come controllate la qualità dei vostri prodotti? Le proprietà chimiche dei prodotti rispettano gli standard di qualità?

Con un team di qualità professionale, pianificazione avanzata della qualità del prodotto, implementazione rigorosa e miglioramento continuo, emetteremo il certificato di ispezione della qualità del prodotto, incluso il rapporto di analisi chimica.

La vostra azienda può fornire dati tecnici dettagliati e disegni?

Sì, è possibile. Per favore, diteci quali prodotti e applicazioni avete bisogno, e vi invieremo dati tecnici dettagliati e disegni per la vostra valutazione e conferma.

Come gestite il servizio prima e dopo la vendita?

Abbiamo un team commerciale professionale che lavorerà in modo one-on-one per proteggere le vostre esigenze di prodotto, e se avete domande, lui potrà rispondervi!

Posso visitare la tua fabbrica prima di fare un ordine?

Sì, sei il benvenuto per visitare la nostra fabbrica. Siamo felici di avere l'opportunità di conoscerci.

Dove si trova la tua base di produzione?

Produciamo i nostri prodotti in Jiangsu, Cina e li spediamo dalla Cina al tuo paese il prima possibile, il che dipende generalmente dai requisiti del prodotto e dalla quantità.

Puoi mandarmi dei campioni?

- Sì, possiamo.