Invar36 Alloy Sheets for Accurate Dimensional Stability in Aerospace Components

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

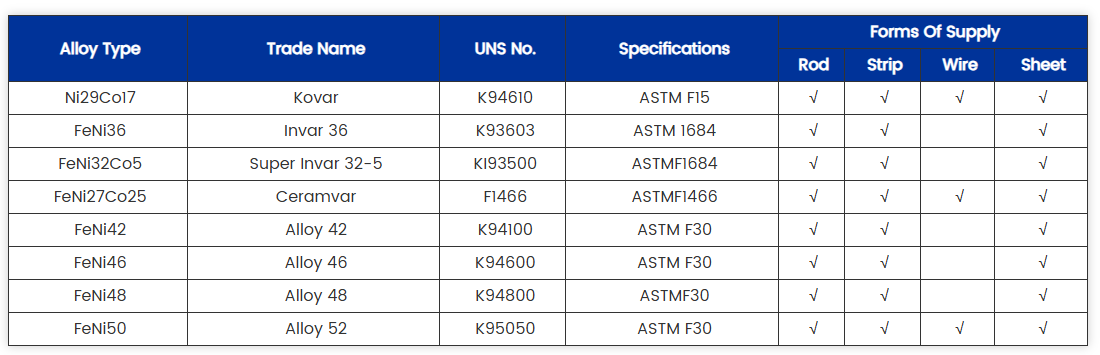

- Specification

- About Us

- FAQs

- Recommended Products

-

Aerospace Structural Components: Invar36 sheets are frequently used in aircraft fuselages, wing structures, and other critical aerospace components where dimensional stability is essential. The high thermal stability prevents these parts from warping or deforming as they experience temperature fluctuations during flight, especially when transitioning from high-speed flight to lower speeds at different altitudes.

-

Satellite Components: Satellites are exposed to extreme temperature variations as they orbit the Earth, transitioning from the cold of space to the warmth of the sun. Invar36 alloy sheets are used in the structural supports, frames, and components of satellites. The alloy’s low expansion coefficient ensures that satellite components maintain their accuracy and alignment, contributing to the overall functionality and reliability of the satellite in space.

-

Precision Instrumentation: Invar36 sheets are also used in precision instruments that require highly stable and accurate measurements in challenging conditions. The aerospace sector often utilizes thermally sensitive sensors and optical instruments, where even minor changes in dimensions could lead to significant measurement errors. Invar36 provides the necessary dimensional stability to avoid such issues.

-

Aerospace Tooling: Components like jigs, fixtures, and molds that are used for precision manufacturing of aerospace parts benefit from the use of Invar36 alloy sheets. The material helps in ensuring that the tooling remains stable and does not distort during the manufacturing process, which is critical for maintaining tight tolerances.

-

Thermal Shields: Invar36 alloy sheets are used in thermal protection systems of aircraft and spacecraft. These components protect against temperature extremes while maintaining their structure and performance. The alloy's low thermal expansion properties ensure that the shields remain intact under high heat and pressure.

-

Dimensional Stability: The primary requirement for aerospace components is dimensional stability under a range of temperature changes. Invar36’s low CTE ensures that components maintain their shape and function despite exposure to varying temperatures, making it ideal for aerospace applications where precision is paramount.

-

Thermal Resistance: Components used in the aerospace industry, especially those in space exploration or high-altitude flight, are exposed to significant temperature fluctuations. Users require materials that can maintain structural integrity and functionality even under extreme temperatures, whether in the deep cold of space or the heat generated during high-speed flight. Invar36 provides the thermal resistance required for these challenging environments.

-

High Precision and Accuracy: Aerospace users demand precision in every component, as even the slightest deviation can have serious consequences. Invar36 alloy’s inherent accuracy and stable dimensions make it an excellent choice for applications where high precision is critical.

-

Material Reliability: The aerospace sector requires materials that are not only stable and precise but also highly reliable under prolonged exposure to harsh conditions. Invar36 offers excellent mechanical properties, including strength, resilience, and corrosion resistance, ensuring that components remain durable and effective over time.

-

Lightweight and Strong: While dimensional stability is crucial, aerospace components also need to be lightweight without sacrificing strength. Invar36 provides an excellent balance of lightness and strength, ensuring that aerospace structures and components can perform efficiently without adding unnecessary weight.

-

Cost Efficiency: Although Invar36 offers advanced performance characteristics, it must also be a cost-effective solution for manufacturers. Aerospace companies demand materials that offer long-term value, reducing the need for frequent replacements or repairs. The durability and reliability of Invar36 alloy sheets contribute to reducing long-term operational costs.

-

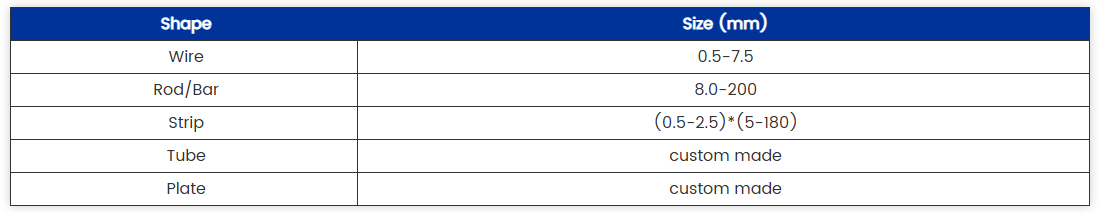

Customization and Versatility: Invar36 alloy sheets can be customized to fit various shapes, sizes, and thicknesses to meet the specific needs of different aerospace components. Customizability ensures that manufacturers can obtain the material in the required form, whether it is in sheet, plate, or foil configurations.

Invar36, also known as 36% nickel iron alloy, is renowned for its remarkable dimensional stability and low coefficient of thermal expansion (CTE). These unique properties make it an ideal material for applications requiring minimal expansion or contraction due to temperature changes. Invar36 alloy is primarily composed of iron and nickel, with a special emphasis on precision and stability, even under extreme conditions. This makes it one of the most trusted materials in industries where accuracy is crucial, particularly in the aerospace sector.

Applications of Invar36 Alloy Sheets

Invar36 alloy sheets are widely utilized in the aerospace industry due to their exceptional dimensional stability. The aerospace sector demands high-precision components that can withstand significant temperature fluctuations without distorting or losing their shape. The low CTE of Invar36 ensures that parts maintain their dimensional accuracy, even in environments with extreme thermal stresses. Some key applications include:

User Demands and Requirements

Users of Invar36 alloy sheets, especially in the aerospace industry, have several key requirements and demands that the material must meet:

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

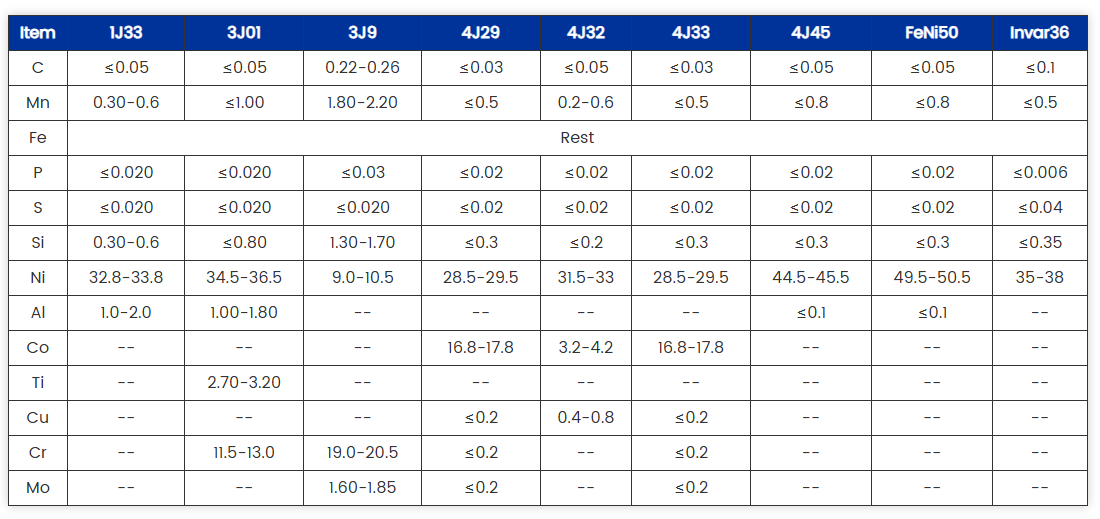

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.