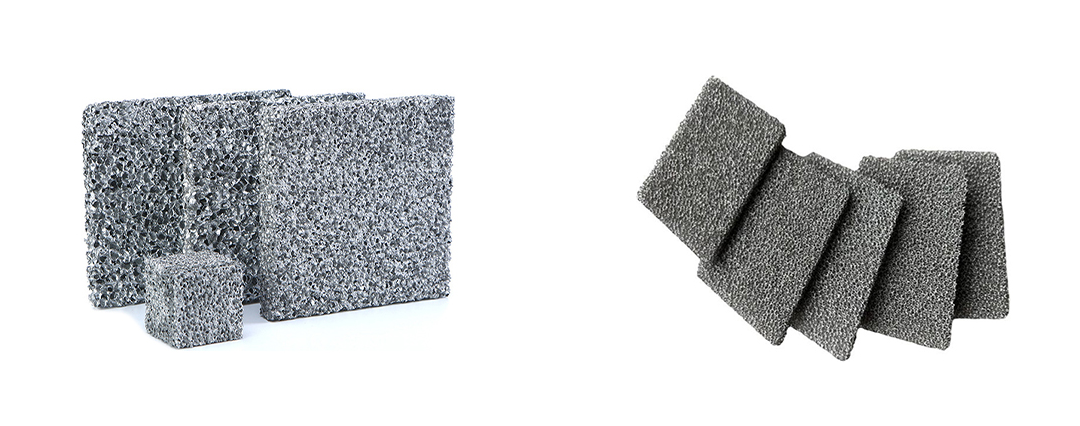

Innovative Foam Nickel for Efficient Thermal Management in Aerospace and High-Temperature Applications

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

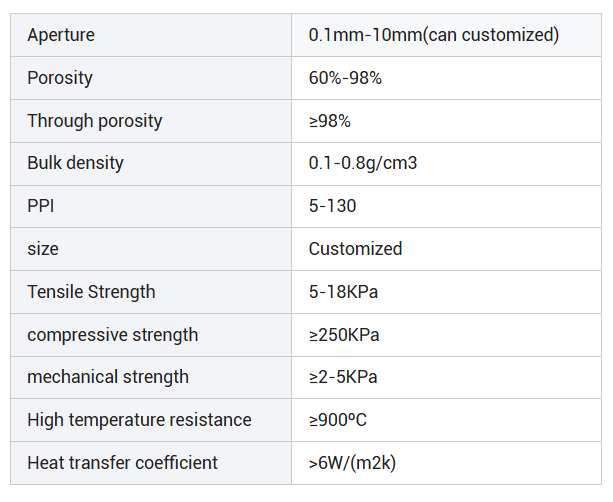

- Specification

- About Us

- FAQs

- Recommended Products

-

Heat Dissipation in Aerospace Electronics

- Aerospace systems, including avionics, satellite communication devices, and radar systems, require efficient heat dissipation to prevent overheating and ensure reliable performance.

- Foam nickel’s high thermal conductivity and large surface area enable effective heat transfer, helping maintain optimal operating temperatures in extreme aerospace conditions.

-

Thermal Protection for Jet Engines and Spacecraft Components

- Foam nickel is used in heat shields and thermal barriers to protect jet engines, spacecraft, and propulsion systems from extreme heat exposure.

- Its ability to withstand high temperatures while maintaining structural integrity ensures long-lasting performance in harsh aerospace environments.

-

Cooling Solutions for High-Power Electronics

- Power electronics in military aircraft, satellites, and space probes generate significant heat, requiring advanced cooling solutions.

- Foam nickel serves as a heat sink material, improving thermal conductivity and enhancing cooling efficiency for longer operational lifespan.

-

Heat Exchangers for Extreme Environments

- Foam nickel is widely used in compact heat exchangers for high-temperature industrial and aerospace applications.

- Its porous structure enhances fluid flow, ensuring maximum heat transfer efficiency in high-performance cooling systems.

- Exceptional Thermal Conductivity: Foam nickel efficiently dissipates heat, reducing the risk of thermal failure in aerospace and high-power systems.

- Lightweight and Strong: Unlike traditional heat-dissipating materials, foam nickel offers a high strength-to-weight ratio, making it ideal for weight-sensitive aerospace applications.

- Corrosion and Oxidation Resistance: Foam nickel performs exceptionally well in high-temperature and corrosive environments, ensuring long-lasting durability.

- Enhanced Energy Efficiency: Its high porosity and large surface area maximize heat transfer, contributing to energy savings and improved system performance.

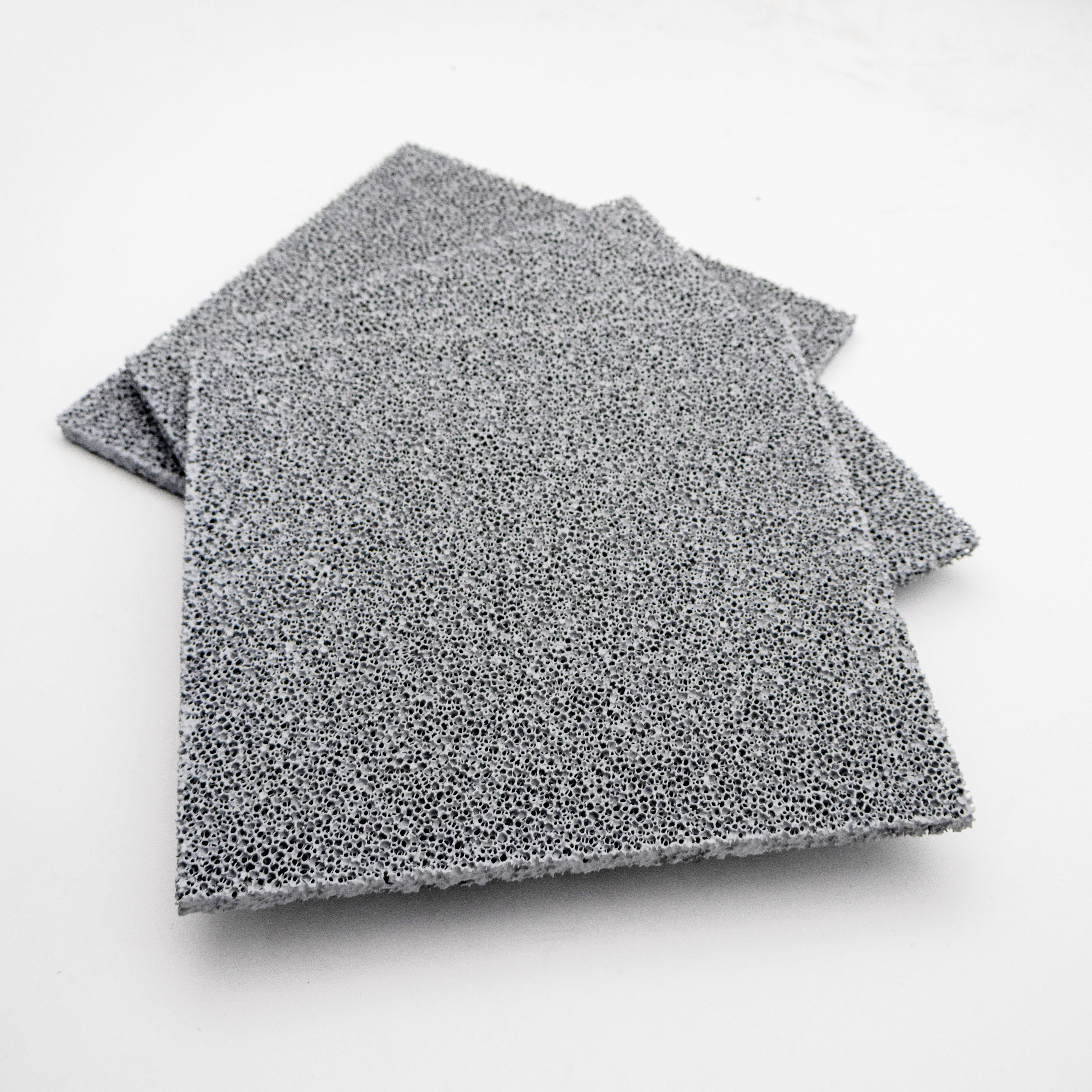

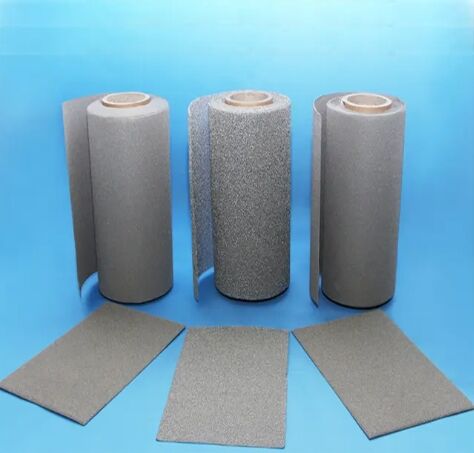

With the increasing demand for high-performance thermal management solutions, foam nickel has emerged as an innovative material for aerospace and high-temperature applications. Its lightweight, porous structure, and exceptional thermal conductivity make it an ideal choice for heat dissipation, energy absorption, and temperature control in extreme environments. As industries continue to push the limits of performance and efficiency, foam nickel provides a durable and effective solution for managing heat in critical applications.

Applications of Foam Nickel in Aerospace and High-Temperature Environments

Meeting Industry Needs with Foam Nickel Solutions

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.