Industrial-Grade Inconel X-750 Spring Wire for Superior Fatigue Resistance

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

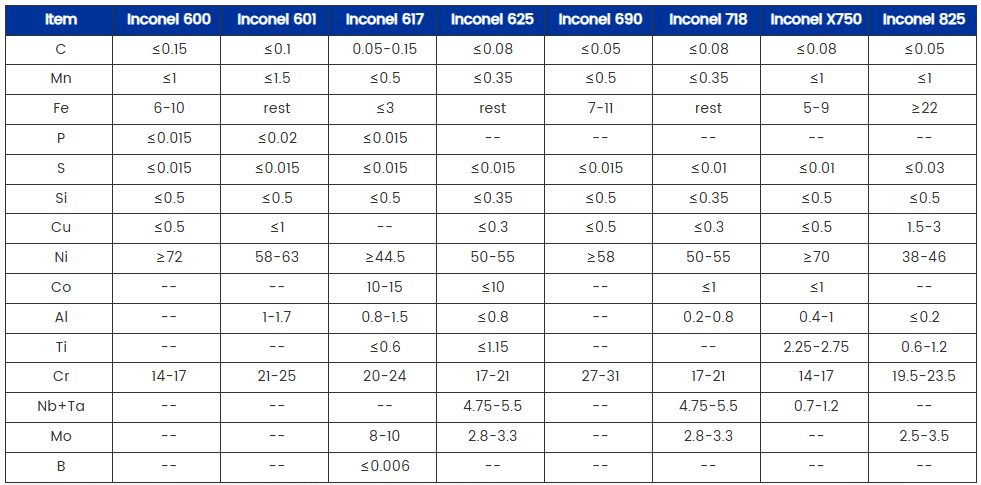

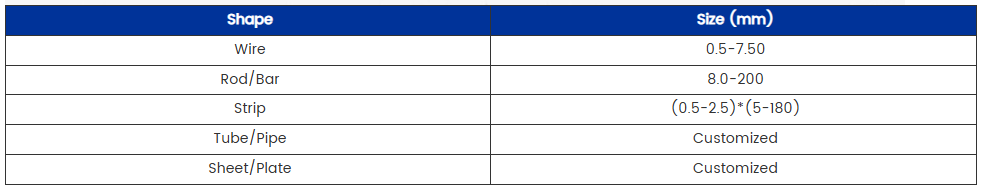

- Specification

- Applications

- FAQs

- Recommended Products

-

Withstands high cyclic loading without failure, ideal for springs in dynamic environments.

-

Maintains structural integrity under repeated stress cycles, outperforming conventional steels.

-

Retains strength up to 1300°F (700°C), making it suitable for jet engines and turbine components.

-

Excellent creep resistance under prolonged stress at elevated temperatures.

-

Resists chloride stress corrosion cracking, sulfuric acid, and seawater exposure.

-

Forms a protective oxide layer, preventing degradation in harsh chemical environments.

-

Tensile strength: ~160-180 ksi (1100-1240 MPa) after heat treatment.

-

Yield strength: ~95-120 ksi (655-825 MPa), ensuring long-term reliability.

-

AMS 5667 / AMS 5698 – Aerospace material specifications for heat-treated Inconel X-750.

-

ASTM B637 – Standard for precipitation-hardened nickel alloy bars and wires.

-

Turbine Engine Springs – Used in compressor and combustion sections for high-temperature resilience.

-

Aircraft Landing Gear – Fatigue-resistant springs endure repeated stress during takeoff/landing.

-

Missile & UAV Components – Reliable performance in extreme conditions.

-

Downhole Tool Springs – Withstands high-pressure, corrosive wellbore environments.

-

Valve & Pump Components – Resists sour gas (H₂S) and acidic conditions.

-

Nuclear Reactor Springs – Maintains performance under radiation and thermal cycling.

-

Gas Turbine Components – Used in power plants for high-stress, high-heat applications.

-

Heavy-Duty Compression Springs – For presses, actuators, and vibration damping systems.

-

Chemical Processing Equipment – Springs in pumps, valves, and seals resist corrosive media.

-

With rising air travel and military spending, next-gen jet engines require advanced alloys for higher efficiency and durability.

-

Inconel X-750 is critical for GE, Rolls-Royce, and Pratt & Whitney engine components.

-

Deepwater drilling and sour gas extraction demand materials that resist H₂S cracking and high-pressure fatigue.

-

Inconel X-750 is increasingly used in subsea equipment and fracking tools.

-

Small Modular Reactors (SMRs) and advanced nuclear plants require high-performance alloys.

-

Inconel X-750 is used in control rod mechanisms and reactor cooling systems.

-

3D-printed Inconel X-750 springs are being tested for custom aerospace and medical applications.

-

Powder bed fusion (LPBF) allows complex geometries with maintained fatigue resistance.

-

Nickel price volatility affects raw material costs, but demand remains strong.

-

Manufacturers are optimizing heat treatment processes to enhance performance while reducing waste.

In high-performance industrial applications where extreme stress, temperature, and corrosion resistance are critical, Inconel X-750 spring wire stands out as a premier material choice. This nickel-chromium superalloy is engineered for exceptional fatigue resistance, making it indispensable in aerospace, oil & gas, and power generation industries.

As industries push the limits of mechanical durability and operational longevity, the demand for high-reliability spring materials like Inconel X-750 continues to grow. This article examines its material properties, key applications, and industry trends shaping its adoption.

Material Properties: Why Inconel X-750?Inconel X-750 is a precipitation-hardened nickel alloy optimized for high strength and fatigue resistance. Key characteristics include:

1. Superior Fatigue Resistance

2. High-Temperature Performance

3. Corrosion & Oxidation Resistance

4. Mechanical Strength & Durability

Standards & Specifications

1. Aerospace & Defense

2. Oil & Gas Industry

3. Power Generation

4. Industrial Machinery

1. Growth in Aerospace & Jet Engine Manufacturing

2. Harsher Oil & Gas Exploration Environments

3. Expansion of Nuclear & Renewable Energy

4. Advancements in Additive Manufacturing

5. Supply Chain & Cost Considerations

As industries demand higher performance, longer lifespan, and extreme environment resistance, Inconel X-750 spring wire remains a top-tier solution. Its superior fatigue resistance, high-temperature stability, and corrosion resilience make it irreplaceable in aerospace, energy, and heavy industry.

With advancements in additive manufacturing and increasing extreme-environment applications, Inconel X-750 will continue to evolve as a critical material for next-generation engineering challenges.

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.