Industrial-Grade Inconel 718 Spring Wire for Deep-Sea and Oil & Gas Applications

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

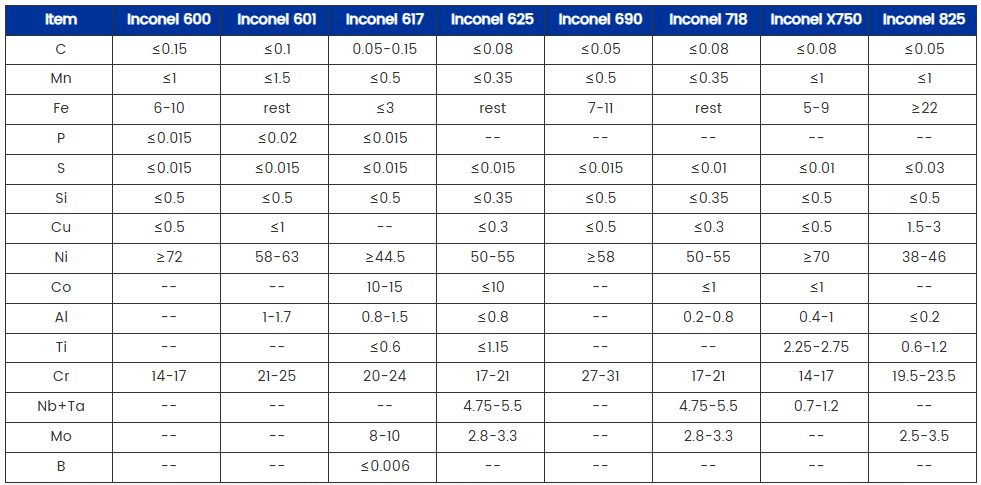

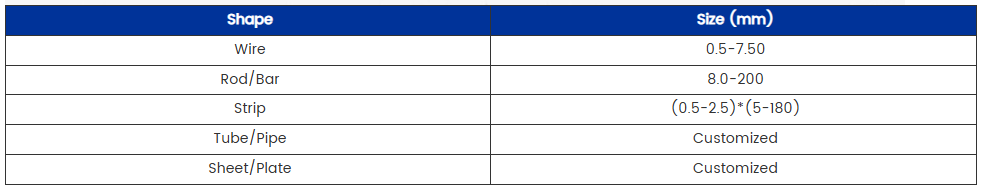

- Specification

- Applications

- FAQs

- Recommended Products

-

Pressure resistance: Maintains structural integrity at depths exceeding 3,000 meters (9,800 ft)

-

Chloride resistance: Exceptional performance in seawater and brine environments

-

Hydrogen sulfide immunity: Resists sour gas corrosion (NACE MR0175 compliant)

-

Temperature stability: Operational range from -40°C to 650°C (-40°F to 1200°F)

-

Fatigue strength: 620 MPa (90 ksi) at 10⁷ cycles in seawater

-

Yield strength: 1,035 MPa (150 ksi) minimum

-

Creep resistance: <0.5% creep strain at 600°C after 1,000 hours

-

Stress relaxation: <15% load loss after 10,000 hours at 200°C

-

ROV and AUV Components

-

Thruster control springs

-

Manipulator tool return mechanisms

-

Pressure compensation systems

-

Subsea Production Equipment

-

Christmas tree valve springs

-

Pipeline connection systems

-

Wellhead control modules

-

Oceanographic Instruments

-

Sensor deployment mechanisms

-

Sampling device return springs

-

Deep-sea camera systems

-

Downhole Tools

-

Formation testing valve springs

-

Safety valve actuation systems

-

Perforating gun components

-

Surface Equipment

-

Blowout preventer (BOP) control springs

-

Surface safety valve mechanisms

-

Pressure relief systems

-

Processing Facilities

-

Sour gas processing valves

-

Corrosive fluid handling systems

-

High-pressure pump components

-

Ultra-deepwater exploration pushing to 4,000+ meter depths

-

Subsea mining equipment requiring durable spring solutions

-

Offshore renewable energy systems needing corrosion-resistant components

-

High-pressure/high-temperature (HPHT) wells demanding enhanced materials

-

Digital oilfield technologies requiring reliable downhole sensors

-

Aging infrastructure refurbishment creating replacement part demand

-

Enhanced Alloy Variants

-

Improved sulfide stress cracking resistance

-

Optimized microstructure for fatigue performance

-

Reduced susceptibility to hydrogen embrittlement

-

Manufacturing Advances

-

Precision wire drawing for consistent diameters (±0.01mm)

-

Advanced heat treatment protocols

-

Surface engineering for extended service life

-

Sustainability Initiatives

-

Recycled content optimization

-

Life extension technologies

-

Environmentally conscious manufacturing processes

In the extreme environments of deep-sea exploration and oil & gas operations, industrial-grade Inconel 718 spring wire has emerged as an engineering solution that combines unmatched corrosion resistance with exceptional mechanical reliability. This nickel-chromium superalloy is specifically engineered to withstand the high-pressure, corrosive, and variable temperature conditions characteristic of subsea and hydrocarbon extraction environments.

Material Properties and Performance Advantages

Extreme Environment Capability

Mechanical Reliability

Critical Industry Applications

Deep-Sea Exploration Systems

Oil & Gas Operations

Emerging Industry Trends

Deep-Sea Technology Advancements

Oil & Gas Sector Developments

Material Innovation Trends

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.