Inconel X-750 Wire – High-Performance Alloy for Springs & Fasteners

We offer factory direct pricing and special discounts for bulk orders. Whether you need small or large quantities, our products are shipped quickly to ensure a reliable supply for industrial projects worldwide.

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

-

Springs for High-Temperature Applications: Inconel X-750 wire is commonly used to produce springs that need to function at elevated temperatures, particularly in gas turbines, jet engines, and industrial systems. The wire's superior strength and fatigue resistance make it ideal for springs subjected to constant mechanical stress and high heat. These springs are essential in components like turbine engines, compressors, and exhaust systems where high strength, resistance to thermal creep, and performance under temperature cycling are critical.

-

Fasteners in Aerospace and Power Generation: Inconel X-750 wire is widely used for making high-strength fasteners, including bolts, nuts, and washers, which are crucial in aerospace and power generation industries. The wire's ability to withstand extreme mechanical forces, combined with excellent resistance to thermal expansion and oxidation, makes it suitable for high-stress fastening applications in jet engines, gas turbines, and other high-temperature industrial systems.

-

Gas Turbines: In gas turbines, fasteners made from Inconel X-750 wire are required to withstand high temperatures and mechanical stresses. The wire’s resistance to thermal fatigue and oxidation ensures that fasteners used in turbine engines remain functional and secure, even in the harshest conditions, preventing failures in mission-critical components.

-

Rocket Propulsion Systems: Rocket engines and propulsion systems experience extreme temperatures and mechanical stresses during operation. Inconel X-750 wire is used in the manufacturing of springs and fasteners in rocket propulsion systems, where it must endure significant temperature changes, high vibration, and mechanical loads. The wire’s ability to retain strength and resistance to oxidation at elevated temperatures makes it ideal for these applications.

-

Industrial Equipment and Chemical Processing: The chemical processing industry also utilizes Inconel X-750 wire for manufacturing components like springs and fasteners that operate in high-temperature environments. The wire’s excellent resistance to oxidation and corrosion, especially in aggressive environments, ensures the reliability and long service life of springs and fasteners used in reactors, heat exchangers, and pressure vessels.

-

Marine and Offshore Equipment: Inconel X-750 wire is also used in marine and offshore applications, including subsea equipment, where high strength and resistance to seawater corrosion are necessary. Springs and fasteners made from Inconel X-750 wire provide the durability and performance needed for components exposed to both high pressure and corrosive environments.

-

UNS N07750: The primary designation for Inconel X-750, UNS N07750, defines the composition and mechanical properties of the alloy. This grade is known for its excellent resistance to oxidation, thermal creep, and high-temperature fatigue, making it suitable for use in springs, fasteners, and other critical components in aerospace and power generation industries.

-

AMS 5681: This specification covers Inconel X-750 wire for aerospace and industrial applications, particularly for components like springs and fasteners. AMS 5681 provides detailed requirements for mechanical properties such as tensile strength, yield strength, and elongation, ensuring the wire meets the performance criteria for high-temperature and high-stress applications.

-

ASTM B805: ASTM B805 is a standard specification that covers Inconel X-750 wire used in welding applications, though it also applies to wire used in other critical applications such as springs and fasteners. The standard outlines the chemical composition, mechanical properties, and testing requirements to ensure the wire’s performance in harsh environments.

-

Melting and Alloying: The production of Inconel X-750 wire begins with the careful melting and alloying of nickel, chromium, and other elements, such as molybdenum and titanium. This is usually done in a vacuum induction furnace or electric arc furnace, which allows precise control over the alloy's composition, ensuring that the wire meets the necessary strength, oxidation resistance, and thermal stability requirements.

-

Wire Drawing: Once the alloy is cast into billets or ingots, it undergoes the wire drawing process. The billets are heated and drawn through a series of progressively smaller dies to reduce the diameter of the wire. This process improves the material’s mechanical properties and flexibility, allowing the wire to be formed into springs, fasteners, or other components while retaining its strength and resistance to high-temperature deformation.

-

Heat Treatment: After the wire is drawn to the desired size, it is heat-treated to enhance its mechanical properties. This typically involves a solution annealing process, followed by aging to strengthen the alloy through the precipitation of fine particles. Heat treatment helps increase the wire's creep resistance, tensile strength, and fatigue resistance, which are critical for high-performance applications like springs and fasteners.

-

Finishing and Quality Control: After heat treatment, the wire undergoes various finishing processes to achieve the desired surface finish and dimensional accuracy. It is then subjected to rigorous quality control testing, including tensile testing, hardness testing, and surface inspection, to ensure it meets the specifications for strength, oxidation resistance, and other key properties. Non-destructive testing methods like ultrasonic testing or eddy current testing may also be used to detect any internal flaws.

-

High Strength and Durability: Inconel X-750 wire must provide excellent strength in high-temperature environments, particularly in aerospace and power generation applications. It needs to maintain its tensile strength and resist creep deformation over long periods, even at temperatures up to 700°C (1290°F).

-

Excellent Oxidation and Corrosion Resistance: Inconel X-750 wire is required to resist oxidation, pitting, and other forms of corrosion, especially in harsh environments like gas turbines, chemical processing plants, and marine applications. This is essential for ensuring the longevity of components like springs and fasteners, which are critical for system integrity.

-

Fatigue Resistance: Springs and fasteners often undergo repeated mechanical stresses, especially in jet engines, turbines, and rocket propulsion systems. Users need Inconel X-750 wire to exhibit excellent fatigue resistance to prevent premature failure due to repeated thermal cycling and mechanical load variations.

-

Weldability and Fabrication Flexibility: Inconel X-750 wire is often used in welding and fabrication processes, so it must offer good weldability and flexibility in fabrication. Users require a material that can be easily formed into different shapes and sizes for specific applications without compromising its high-performance properties.

-

High-Temperature Performance: Inconel X-750 wire must be able to maintain its mechanical properties at elevated temperatures. It is essential that the wire does not lose its strength, ductility, or fatigue resistance when exposed to high temperatures, particularly in environments like jet engines and gas turbines.

-

Dimensional Accuracy: Users of Inconel X-750 wire demand precise dimensions and tolerances to ensure the wire fits correctly into the final assembly. Whether it’s for fasteners or springs, the wire needs to meet stringent size and mechanical property specifications to perform as expected in critical applications.

Introduction to Inconel X-750 Wire

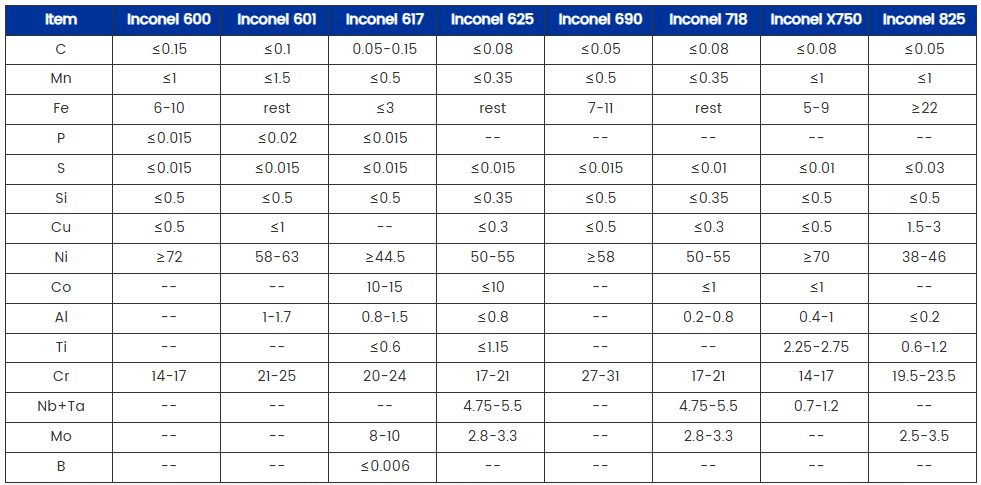

Inconel X-750 is a high-performance nickel-chromium-based superalloy that offers exceptional mechanical properties at elevated temperatures and outstanding resistance to oxidation and corrosion. The alloy is composed primarily of nickel (approximately 72%), chromium (15-17%), and small additions of molybdenum, iron, titanium, and aluminum, which contribute to its outstanding high-temperature strength, excellent fatigue resistance, and resistance to thermal degradation.

Inconel X-750 wire is manufactured to retain these superior properties in the form of a wire, allowing it to be used in various demanding applications such as springs, fasteners, and other components subjected to high temperatures and mechanical stresses. The wire form is ideal for applications requiring both strength and flexibility while maintaining performance in extreme environments.

Applications of Inconel X-750 Wire

Grade & Specifications

Inconel X-750 wire is produced according to several industry standards that ensure its suitability for high-temperature and high-stress applications. Some of the relevant grades and specifications include:

Manufacturing Process of Inconel X-750 Wire

The manufacturing process for Inconel X-750 wire involves several steps to ensure that the wire maintains its high strength, flexibility, and resistance to thermal fatigue and oxidation. The process typically includes the following stages:

User Requirements

Users of Inconel X-750 wire typically operate in industries where components must perform reliably under extreme temperatures, mechanical stresses, and corrosive environments. Some of the key user requirements for Inconel X-750 wire include:

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.