Inconel X-750 Plate – Reliable & Durable Material for Gas Turbines

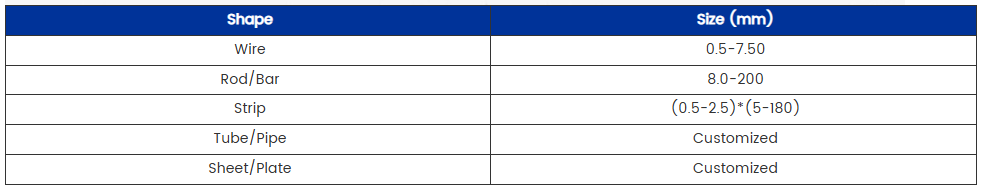

We offer factory direct pricing and special discounts for bulk orders. Whether you need small or large quantities, our products are shipped quickly to ensure a reliable supply for industrial projects worldwide.

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

- High Strength at Elevated Temperatures: Inconel X-750 retains its strength and mechanical integrity at temperatures as high as 1,000°C (1,832°F), making it ideal for gas turbines that operate in such extreme environments.

- Oxidation Resistance: The alloy’s superior oxidation resistance is crucial in turbine applications where components are exposed to high-temperature gases and combustion byproducts that can cause severe corrosion.

- Creep Resistance: Inconel X-750 exhibits excellent resistance to creep, a phenomenon where material deforms over time under constant stress, which is vital for components like turbine blades and discs that must maintain their shape and performance under high mechanical load for extended periods.

- Thermal Fatigue Resistance: The alloy can withstand the repeated heating and cooling cycles that gas turbines experience, preventing thermal fatigue and cracking.

- Good Weldability and Fabrication: Inconel X-750 is also known for its good weldability and machinability, which is essential for producing complex turbine parts and maintaining the efficiency of turbine manufacturing processes.

-

Gas Turbine Components: Inconel X-750 plates are extensively used to manufacture critical components in gas turbines, including turbine blades, vanes, discs, and combustion chambers. These parts are subjected to extreme temperature and mechanical stresses, making it essential to use a material with outstanding high-temperature strength and fatigue resistance. Inconel X-750's ability to withstand continuous high-temperature exposure ensures that gas turbines maintain high efficiency and durability.

-

Aerospace Propulsion Systems: In addition to industrial gas turbines, Inconel X-750 is also used in aerospace propulsion systems, where it is critical for turbine blades and other high-stress components in jet engines. Aerospace applications require materials that can endure extreme temperatures and rapid thermal cycles, and Inconel X-750 delivers excellent performance in such conditions.

-

Power Generation: In the power generation industry, Inconel X-750 plates are used in gas turbines for electricity generation. These turbines often operate at high temperatures, where efficiency and long service life are essential. Inconel X-750’s high creep resistance and oxidation resistance allow for reliable and efficient performance in these high-stress environments.

-

Chemical and Petrochemical Industries: Inconel X-750 plates are also used in the chemical and petrochemical industries, particularly in heat exchangers, reactors, and pressure vessels where high-temperature performance is required. The alloy’s resistance to oxidation and thermal fatigue is critical in environments where high-pressure gases and chemicals are involved.

-

Marine Gas Turbines: In marine applications, Inconel X-750 is used for turbines that power ships, particularly in military and commercial vessels where turbine performance is critical. The alloy’s resistance to high temperatures and corrosion from seawater makes it a preferred material for marine propulsion systems.

-

Industrial Gas Turbines for Compression Systems: Gas turbines used in industrial applications for gas compression also rely on Inconel X-750 plates. These turbines must perform efficiently at high temperatures and under high mechanical stresses, making Inconel X-750 the material of choice due to its resistance to wear, oxidation, and high-temperature creep.

-

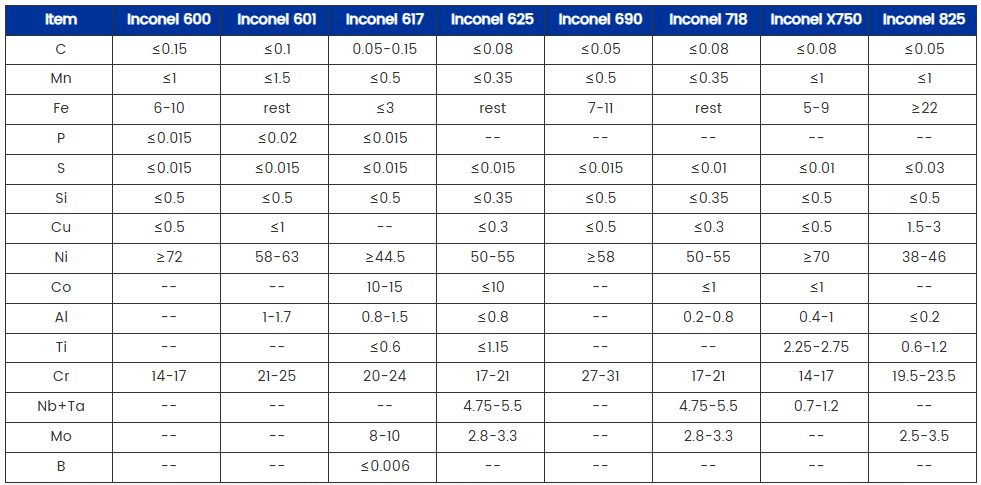

UNS N07750: This is the primary designation for Inconel X-750 and indicates a nickel-chromium-based alloy with molybdenum and aluminum additions. It is widely used in high-temperature applications such as gas turbines, combustion chambers, and aerospace components.

-

AMS 5542: This specification is for Inconel X-750 in plate form, ensuring that the material meets the mechanical properties, such as tensile strength, yield strength, and elongation, required for turbine components and high-temperature applications.

-

ASTM B435: This standard specification covers Inconel X-750 plate and other forms used in gas turbines and other high-temperature industrial applications. It ensures that the material adheres to required chemical composition, dimensional tolerances, and mechanical properties.

-

ISO 9001 Certification: Many Inconel X-750 manufacturers adhere to ISO 9001 standards, ensuring that the material is produced in a controlled environment to meet the highest quality and reliability standards. This certification assures users of consistent quality and performance.

-

Melting and Alloying: The production process begins with the melting of high-quality nickel, chromium, and other alloying elements in a vacuum induction furnace. The precise control of the chemical composition is essential for ensuring the high-temperature strength and oxidation resistance of Inconel X-750.

-

Hot Rolling or Forging: Once the alloy is melted, it is cast into billets and then hot-rolled or forged into plate form. The hot rolling process ensures that the plate has the required thickness and shape for use in turbine components. Forging may also be used for components requiring specific mechanical properties.

-

Heat Treatment: The Inconel X-750 plates undergo heat treatment to optimize their mechanical properties, including solution annealing and aging processes. This heat treatment helps precipitate strengthening phases in the alloy, which enhances its resistance to high-temperature creep and fatigue.

-

Cold Rolling (Optional): For certain applications, the plates may undergo cold rolling to improve surface finish, dimensional accuracy, and uniformity. This is especially important for precision applications where tight tolerances are required.

-

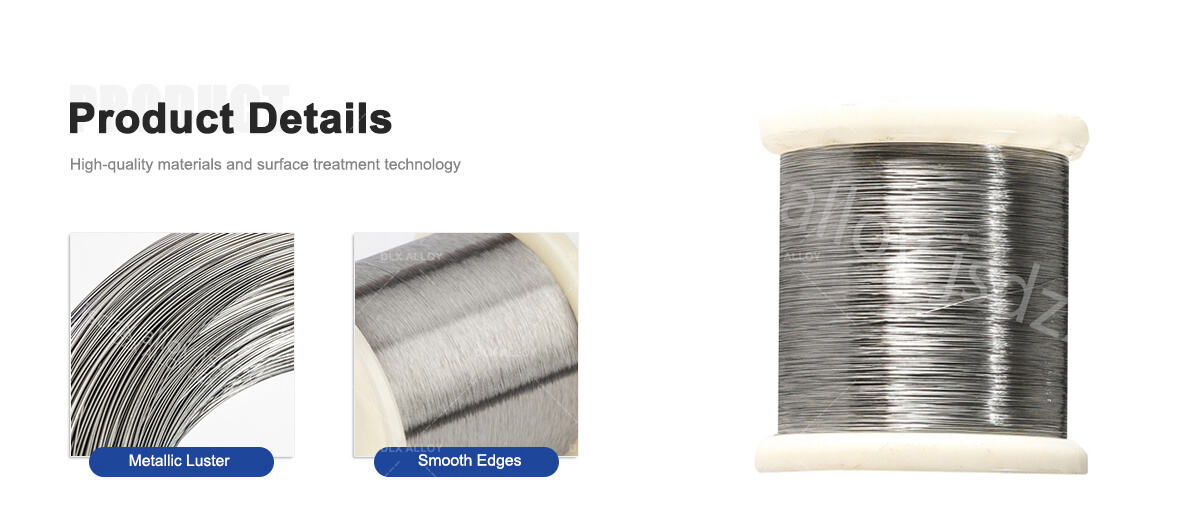

Surface Finishing: Surface finishing processes such as grinding, polishing, or shot peening may be applied to improve the surface quality of the plate. These processes help reduce surface imperfections that could lead to material failure under high-stress conditions.

-

Inspection and Quality Control: Inconel X-750 plates undergo rigorous testing to ensure they meet all required mechanical properties and dimensional tolerances. Common tests include tensile tests, hardness tests, and non-destructive testing methods like ultrasonic or X-ray inspection to detect any internal defects.

-

High Strength at Elevated Temperatures: Inconel X-750 plate must maintain its strength even at temperatures exceeding 1,000°C (1,832°F). This is crucial for turbine blades, discs, and other critical components that experience extreme heat and mechanical stress.

-

Oxidation and Corrosion Resistance: The plate must offer excellent resistance to oxidation and corrosion, particularly when exposed to hot gases, combustion byproducts, and aggressive chemical environments. This ensures the longevity of components used in gas turbines and other high-stress applications.

-

Creep and Fatigue Resistance: Inconel X-750 must exhibit superior resistance to creep, which is the slow deformation of material under sustained high stress at high temperatures. It should also resist thermal and mechanical fatigue caused by repeated heating and cooling cycles.

-

Dimensional Accuracy and Tolerances: Users demand that Inconel X-750 plates be produced to precise dimensional tolerances to ensure proper fit and function in turbine systems. Plates used for turbine components must be cut or machined to exact specifications to avoid issues during assembly and operation.

-

Weldability and Fabrication: The plate must be easily fabricated and welded into complex turbine shapes without compromising its mechanical properties. Inconel X-750 is known for its good weldability, which allows it to be used in complex gas turbine designs.

-

Consistency and Quality: Users expect the material to be of consistent quality, with properties that meet the required specifications. This ensures that turbine components made from Inconel X-750 plates can perform reliably over long periods without failure.

Inconel X-750 is a high-performance, nickel-based superalloy renowned for its exceptional mechanical properties, particularly in high-temperature environments. It is widely used in demanding industrial applications, where components must withstand extreme heat, stress, and corrosion. One of the most important applications of Inconel X-750 is in gas turbines, where the alloy's high strength, oxidation resistance, and excellent creep resistance make it the ideal material for critical turbine components. When manufactured into plate form, Inconel X-750 offers versatility and reliability for engineers designing and producing parts for gas turbines that require high performance in the harshest conditions.

Material Properties of Inconel X-750 Plate

Inconel X-750 is made primarily from a nickel-chromium matrix with additions of molybdenum, iron, and other elements to enhance its mechanical properties and resistance to high-temperature oxidation. The alloy is well-known for its:

Applications of Inconel X-750 Plate

Grade & Specifications

Inconel X-750 is manufactured according to strict standards to ensure that it meets the demanding requirements of gas turbine applications. Common grades and specifications for Inconel X-750 plates include:

Manufacturing Process of Inconel X-750 Plate

The manufacturing of Inconel X-750 plate involves several key steps to ensure its mechanical properties and performance in high-temperature environments:

User Requirements for Inconel X-750 Plate

For users in industries like aerospace, power generation, and chemical processing, Inconel X-750 plates must meet several critical requirements to ensure reliable performance in high-temperature environments:

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.