Inconel 718 Plate – Best Choice for Turbine Blades & Cryogenic Tanks

We offer factory direct pricing and special discounts for bulk orders. Whether you need small or large quantities, our products are shipped quickly to ensure a reliable supply for industrial projects worldwide.

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

-

Turbine Blades in Jet Engines: Inconel 718 plate is a primary material used in the aerospace industry, particularly for turbine blades in jet engines. The material’s ability to withstand high temperatures (up to 700°C) without losing its strength makes it an excellent choice for turbine blades, where it must endure the high heat and mechanical stresses produced during flight. Inconel 718's resistance to thermal fatigue, oxidation, and creep makes it ideal for these high-performance applications.

-

Cryogenic Tanks and Rocket Motors: Another important application for Inconel 718 plate is in cryogenic tanks used in space exploration and rocket motors. In these systems, the material must withstand extremely low temperatures, often below -250°C (-418°F). Inconel 718 has been specifically engineered to perform under both high-temperature and cryogenic conditions, making it the perfect choice for cryogenic tanks and associated components used in the storage and transport of liquefied gases like liquid hydrogen and liquid oxygen.

-

Gas Turbines and Power Generation: In power plants and other energy systems, Inconel 718 plate is used in critical turbine components. The material’s excellent performance in high-temperature environments ensures that components such as blades, rotors, and stators in gas turbines can endure the high stresses encountered during energy generation. Its ability to resist oxidation and thermal creep at temperatures exceeding 700°C allows for reliable, long-term operation in these demanding applications.

-

Chemical Processing Equipment: Inconel 718 is also used in the chemical processing industry for applications where resistance to both heat and corrosion is paramount. Tanks, reactors, and other high-temperature components that are exposed to aggressive chemicals are often made from Inconel 718, as it provides long-lasting durability in corrosive environments.

-

Marine and Offshore Applications: Inconel 718 plate is utilized in marine turbines, deep-sea drilling operations, and other offshore equipment where components are exposed to both high pressure and corrosive saltwater. Its corrosion resistance, high strength, and fatigue resistance make it a suitable material for such high-performance and high-stress applications.

-

UNS N07718: This is the standard designation for Inconel 718. It is widely used for components that need to withstand high temperatures and mechanical stresses. UNS N07718 plate is known for its superior strength, oxidation resistance, and thermal stability at high temperatures, making it ideal for turbine blades, cryogenic tanks, and aerospace applications.

-

AMS 5596: This specification is for Inconel 718 plate used in aerospace applications. AMS 5596 is particularly suited for critical turbine blades and engine components that are exposed to extreme temperatures and mechanical loads during operation.

-

AMS 5590: This is another specification for Inconel 718 plate, commonly used for aerospace parts. It is specifically designed for applications requiring high fatigue and creep resistance, such as turbine blades and rocket engine components.

-

DIN 2.4668: The European standard equivalent of UNS N07718, this grade is used for the same critical applications, including turbine blades, cryogenic tanks, and components in high-temperature environments. The composition and performance characteristics align closely with the ASTM standards used in the US.

-

Melting and Alloying: The production of Inconel 718 plate begins with the melting of high-purity nickel, chromium, molybdenum, niobium, and titanium alloys in a vacuum induction furnace or electric arc furnace. The precise control of the alloying process ensures the material has the correct chemical composition and properties, including excellent oxidation resistance, strength, and resistance to thermal fatigue.

-

Casting and Forming: After the alloy is melted, it is cast into large billets or ingots. The billets are then heated and forged to refine the material and give it the required shape. This step also ensures uniformity in the grain structure, which is crucial for maintaining high strength and resistance to creep under extreme conditions.

-

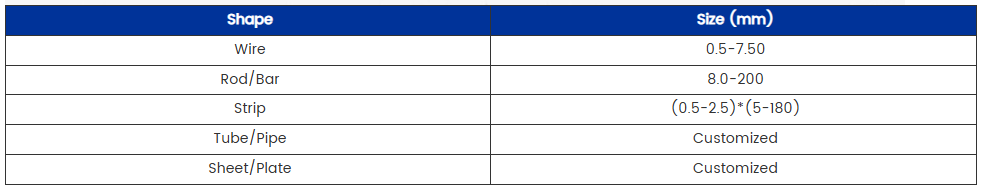

Rolling and Plate Formation: The forged billets are then hot rolled into large plates of varying thickness. The rolling process refines the material’s grain structure and improves its mechanical properties, particularly its strength and fatigue resistance. The thickness of the plate is carefully controlled to meet the specific requirements of turbine blades, cryogenic tanks, and other applications.

-

Heat Treatment: Inconel 718 plate undergoes a heat treatment process consisting of solution annealing followed by aging. Solution annealing is used to relieve stresses and homogenize the microstructure, while aging is done to strengthen the material through precipitation hardening. This heat treatment process ensures that the material can perform at its highest level under both high-temperature and cryogenic conditions.

-

Finishing and Inspection: After the heat treatment, Inconel 718 plate is subjected to finishing processes to achieve the required surface finish and dimensions. The plate is then inspected for any internal defects or irregularities. Common inspection techniques include ultrasonic testing, eddy current testing, and X-ray inspection. Dimensional measurements are also taken to ensure that the plate meets the necessary specifications for its intended application.

-

High Strength and Fatigue Resistance: Inconel 718 plate must exhibit excellent tensile strength and resistance to fatigue, especially in turbine blades and components that are subject to cyclic loading and high mechanical stresses. The material must maintain its integrity over long periods of use, even under extreme operational conditions.

-

High-Temperature Resistance: For applications in jet engines, turbines, and other high-temperature systems, Inconel 718 plate must retain its strength and performance at temperatures exceeding 700°C (1290°F). Its ability to withstand thermal creep and oxidation makes it ideal for components that operate in environments with fluctuating temperatures.

-

Cryogenic Performance: In cryogenic applications, Inconel 718 plate is expected to retain its mechanical properties at extremely low temperatures, often below -250°C (-418°F). The material must maintain its toughness, dimensional stability, and resistance to embrittlement even in these harsh conditions.

-

Corrosion and Oxidation Resistance: Components exposed to harsh environments, such as chemical processing units, marine applications, and power generation turbines, demand materials that resist oxidation and corrosion. Inconel 718’s excellent corrosion resistance ensures its long-term durability in aggressive conditions.

-

Dimensional Precision: Users in aerospace and power generation require Inconel 718 plate to meet precise dimensional specifications. Tight tolerances are necessary to ensure that the plate fits into complex assemblies and performs reliably under high-pressure and high-temperature conditions.

-

Weldability and Fabrication Ease: Inconel 718 plate should also be easily weldable and adaptable to various fabrication techniques. Its good weldability ensures that it can be integrated into complex systems without compromising its strength or resistance to high temperatures.

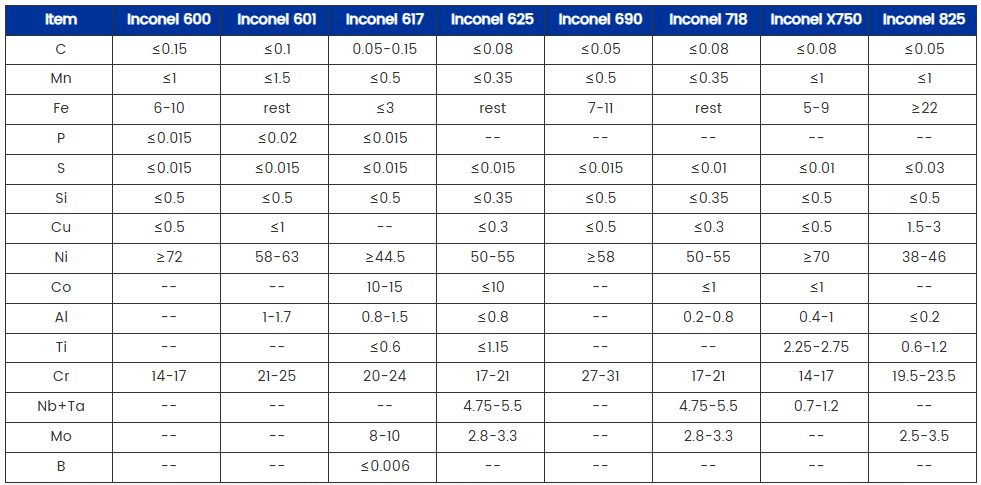

Inconel 718 is a high-performance nickel-chromium superalloy, known for its exceptional strength, oxidation and corrosion resistance, as well as its excellent performance at elevated temperatures. The alloy is primarily composed of nickel (50-55%), chromium (17-21%), and key elements such as molybdenum, niobium, and titanium, which confer remarkable properties, making Inconel 718 an ideal material for critical aerospace, power generation, and cryogenic applications.

Inconel 718 plate is produced in a variety of thicknesses and is widely used in high-stress, high-temperature environments, where materials must maintain their mechanical integrity under challenging conditions. Thanks to its high yield strength, fatigue resistance, and ability to resist thermal creep, Inconel 718 plate is especially well-suited for manufacturing turbine blades and cryogenic tanks, where extreme conditions of pressure, temperature, and mechanical stress prevail.

Applications of Inconel 718 Plate

Grade & Specifications

Inconel 718 plate is manufactured to meet specific industry standards and grades to ensure it meets the exacting requirements of applications like turbine blades and cryogenic tanks. Some of the key specifications include:

Manufacturing Process of Inconel 718 Plate

The manufacturing process of Inconel 718 plate involves a series of steps to ensure that the material meets the required specifications for high-performance applications. These processes are designed to enhance the material’s mechanical properties and ensure the consistency of the plate’s dimensions and quality.

User Requirements

Users of Inconel 718 plate typically have demanding requirements due to the high-performance nature of the applications. Some of the key user demands include:

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.