Inconel 690 Wire – Ideal for High-Corrosion Industrial Applications

We offer factory direct pricing and special discounts for bulk orders. Whether you need small or large quantities, our products are shipped quickly to ensure a reliable supply for industrial projects worldwide.

- Overview

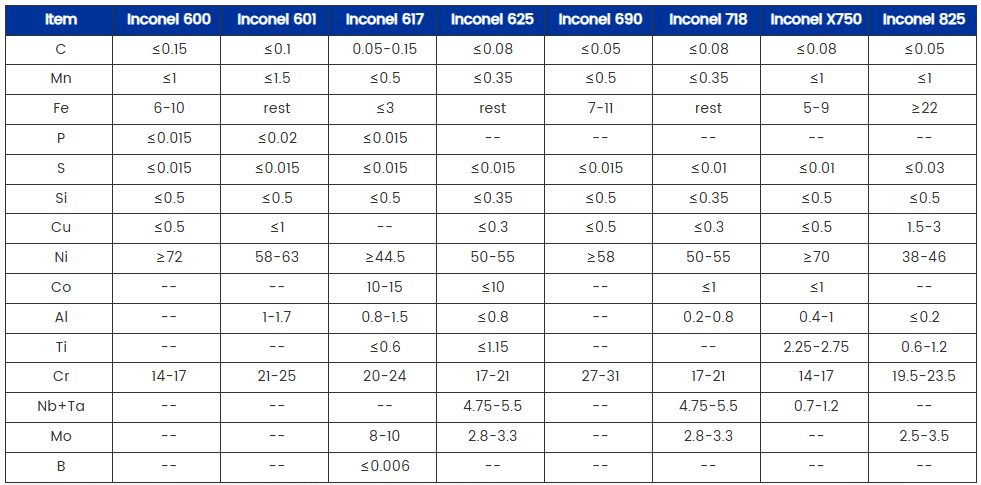

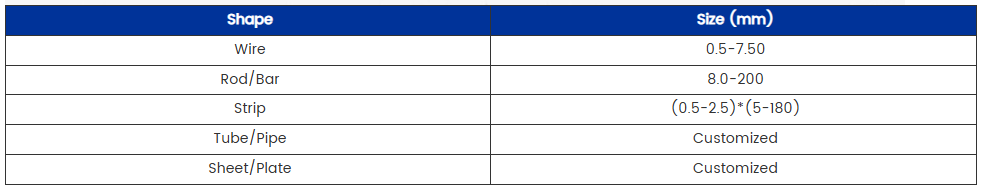

- Specification

- Applications

- FAQs

- Recommended Products

-

Chemical Processing: Inconel 690 wire is frequently used in chemical processing industries, where it is exposed to a wide range of aggressive chemicals at high temperatures. The alloy's resistance to sulfur compounds, acids, and other corrosive substances makes it ideal for applications such as reactor components, piping, and heat exchangers in chemical plants.

-

Petrochemical and Oil Refining: The oil and gas industry demands materials that can withstand extreme temperatures and exposure to corrosive substances such as hydrogen sulfide, sulfur dioxide, and other by-products of refining processes. Inconel 690 wire is used in various applications, including high-temperature piping, flare lines, and reactor internals, providing superior performance in environments prone to corrosion and high mechanical stresses.

-

Nuclear Power Plants: Inconel 690 wire is used in nuclear power plants for components that must withstand both high temperatures and the corrosive effects of radiation. It is commonly employed for steam generator tubing, reactor core components, and other critical parts exposed to highly corrosive and thermally demanding conditions.

-

Aerospace and Jet Engine Components: Due to its high resistance to oxidation and high temperature stability, Inconel 690 wire is used in various aerospace applications, including turbine blades, exhaust systems, and other components that are exposed to extreme heat and corrosive gases. It helps maintain the strength and performance of jet engine parts under high-stress conditions.

-

Marine and Offshore Equipment: Inconel 690 wire is ideal for marine and offshore applications where components are exposed to saltwater and harsh marine environments. The alloy’s resistance to saltwater corrosion makes it a top choice for seawater-cooled equipment, marine turbines, and other critical infrastructure that is exposed to continuous seawater immersion.

-

Waste Incinerators and High-Temperature Furnaces: The extreme temperatures and corrosive nature of the gases generated by waste incineration and industrial furnaces require materials that can withstand both high heat and chemical exposure. Inconel 690 wire is used in components such as burners, heat exchangers, and structural parts in these high-temperature industrial environments.

-

UNS N06690: This is the primary specification for Inconel 690, offering excellent corrosion resistance and high-temperature performance. It is the most widely used grade for applications requiring resistance to both oxidation and corrosion in aggressive environments, particularly in the chemical processing and nuclear industries.

-

AMS 5581: This specification refers to a high-strength, solution-annealed version of Inconel 690, which is commonly used in applications requiring exceptional mechanical properties at elevated temperatures. It is suitable for use in industries like aerospace and power generation.

-

DIN 2.4642: The European equivalent of UNS N06690, this grade of Inconel 690 is commonly used in various applications in chemical, petrochemical, and power generation industries where resistance to corrosion and high-temperature oxidation is critical.

-

Melting and Alloying: The base materials, including nickel, chromium, iron, and other alloying elements, are melted together in a vacuum induction furnace or electric arc furnace. This process ensures that the alloy composition is accurate and consistent, which is crucial for the alloy’s high-performance characteristics.

-

Drawing: After the alloy is cast into billets or rods, the material is drawn through a series of dies to form wire. This process reduces the diameter of the material while preserving its mechanical properties, allowing the wire to achieve the desired size and shape for specific applications.

-

Heat Treatment: Inconel 690 wire is often heat-treated, including solution annealing, to relieve internal stresses and optimize the alloy’s properties. Heat treatment improves the wire’s strength, ductility, and resistance to oxidation at elevated temperatures.

-

Finishing and Coating: Once the wire has been drawn and heat-treated, it may be coated or finished to enhance its properties further. Inconel 690 wire is sometimes coated with an additional layer of protection, depending on the specific needs of the application, to enhance its resistance to chemical attack or wear.

-

Inspection and Quality Control: Stringent quality control procedures are applied throughout the manufacturing process to ensure the wire meets industry standards. This includes mechanical testing, dimensional verification, and surface inspection to detect any defects or inconsistencies in the wire. Non-destructive testing (NDT) methods, such as ultrasonic testing, are commonly used to ensure the integrity of the wire.

Inconel 690 is a high-performance nickel-chromium alloy that is designed to offer exceptional resistance to high-temperature oxidation and corrosion in a variety of aggressive industrial environments. Composed primarily of nickel (58-63%) and chromium (27-30%), Inconel 690 is highly resistant to oxidation, carburization, and sulfidation, even at elevated temperatures. It also contains small amounts of iron, molybdenum, and titanium, which further enhance its mechanical properties and resistance to both high-temperature and high-corrosion environments.

The alloy's combination of outstanding oxidation resistance and mechanical strength makes Inconel 690 ideal for demanding industrial applications, particularly where harsh chemical exposure and extreme operating temperatures are common.

Applications of Inconel 690 Wire

Inconel 690 wire is commonly used in industries where components are exposed to high-temperature and high-corrosion environments. Some of the key applications include:

Grade & Specifications

Inconel 690 is available in various grades and forms, including wire, rods, sheets, and tubes. The following are common grades and specifications for Inconel 690 wire:

Manufacturing Process

The manufacturing process of Inconel 690 wire is designed to ensure that the final product retains the alloy’s desirable properties, such as resistance to corrosion and high-temperature strength. The key stages in the production of Inconel 690 wire include:

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.