Inconel 601 Tube – Perfect for Furnace & Thermal Processing Equipment

We offer factory direct pricing and special discounts for bulk orders. Whether you need small or large quantities, our products are shipped quickly to ensure a reliable supply for industrial projects worldwide.

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

-

Furnace Components: Used in radiant tubes, muffles, and retorts for heat treatment processes.

-

Thermal Processing Equipment: Applied in industrial ovens, kilns, and annealing chambers.

-

Chemical Processing: Ideal for heat exchangers and reactors exposed to corrosive chemicals and high heat.

-

Power Generation: Utilized in boiler components, superheaters, and gas turbines.

-

Petrochemical Industry: Suitable for steam reforming tubes and high-temperature piping systems.

-

ASTM B167 / ASME SB167: Covers seamless nickel-chromium-iron alloy pipes and tubes.

-

ASTM B168 / ASME SB168: Covers plates, sheets, and strips for tube manufacturing.

-

ASTM B516 / ASME SB516: Covers welded tubes of Inconel 601.

-

UNS N06601: The unified numbering system (UNS) designation for Inconel 601.

-

Melting and Alloying: The raw materials are melted in vacuum or electric arc furnaces to achieve precise chemical composition.

-

Hot and Cold Working: The alloy is extruded or drawn to achieve the desired tube dimensions.

-

Heat Treatment: Solution annealing enhances corrosion resistance and mechanical properties.

-

Welding and Fabrication: Welded tubes undergo precision welding processes to ensure structural integrity.

-

Testing and Quality Control: Tubes undergo rigorous testing, including mechanical, corrosion resistance, and non-destructive testing (NDT).

Inconel 601 is a high-performance nickel-chromium-iron alloy known for its exceptional oxidation resistance and high-temperature strength. Inconel 601 tubes are widely used in furnace and thermal processing equipment, where durability and reliability under extreme thermal conditions are critical.

Material Overview

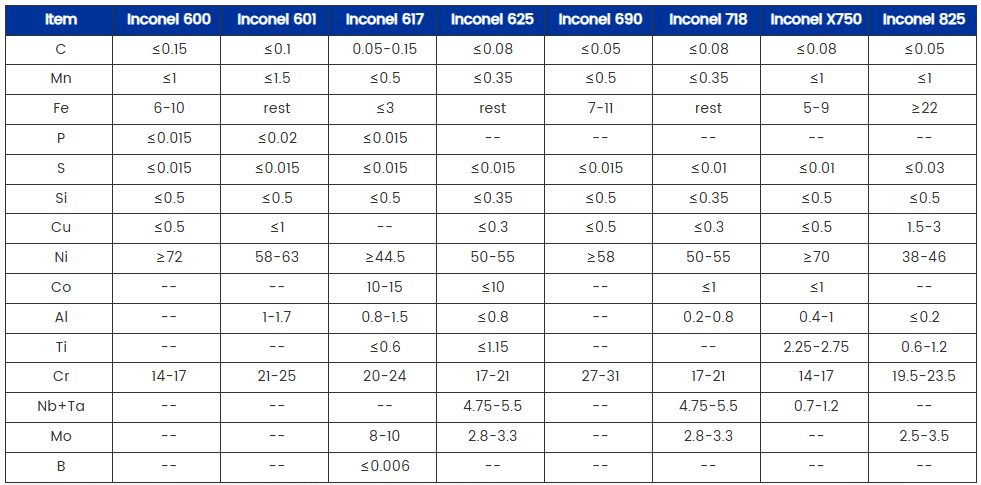

Inconel 601 is primarily composed of nickel (58-63%), chromium (21-25%), and iron, with small amounts of aluminum and other elements. This composition enhances its resistance to oxidation, carburization, and high-temperature corrosion. The alloy retains its mechanical properties even after prolonged exposure to elevated temperatures, making it ideal for furnace and heat-processing applications.

Applications

Thanks to its superior properties, Inconel 601 tubes are extensively used in industries that require resistance to high temperatures and aggressive environments, including:

Grades and Specifications

Inconel 601 tubes are available in different grades and specifications to meet industrial requirements. Some common standards include:

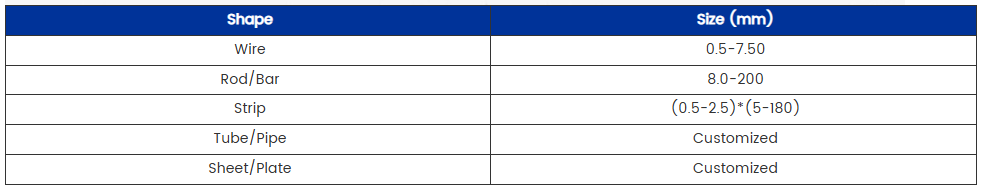

These tubes come in various diameters, wall thicknesses, and finishes to accommodate diverse applications.

Manufacturing Process

The production of Inconel 601 tubes involves several critical steps to ensure high quality and performance:

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.